What are the sheet metal parts of energy storage chassis?

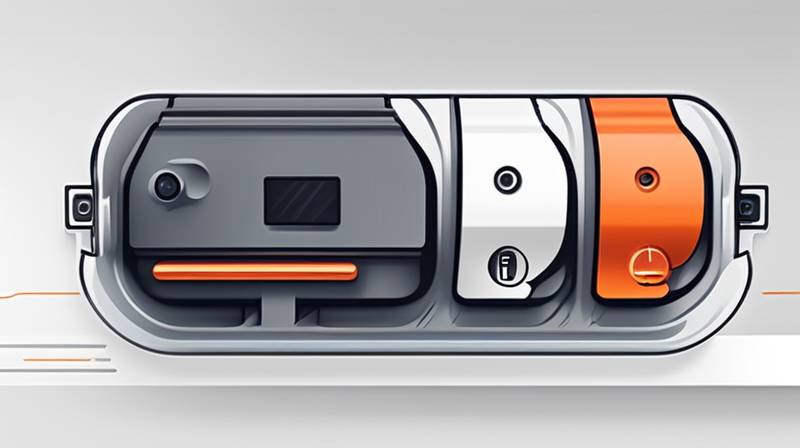

1. Sheet metal components are essential in energy storage chassis, specifically providing structural integrity and housing for various electrical systems. 2. These components, including brackets, enclosures, panels, and frames, are designed to withstand environmental factors while maintaining safety and durability. 3. Adequate selection of materials and manufacturing techniques directly impacts the performance and longevity of the chassis. 4. The functionality and aesthetic of the energy storage solution rely heavily on the precise engineering of these sheet metal parts.

1. SIGNIFICANCE OF SHEET METAL IN ENERGY STORAGE CHASSIS

Sheet metal serves as a fundamental element in the design and manufacture of energy storage chassis, heavily influencing the device’s overall efficiency and reliability. The primary role of this material is to form a robust framework that can endure physical stress and safeguard sensitive electronic components. The importance of durability cannot be overstated; energy storage systems often operate in harsh conditions, requiring materials that can withstand temperature fluctuations, humidity, and even potential impacts from the surrounding environment.

Moreover, the fabrication process of sheet metal contributes to its lightweight advantage, making it a preferred choice in the energy sector. Lighter materials not only facilitate easier transportation and installation but also improve the overall energy efficiency of the system. An effective chassis design incorporating lightweight sheet metal can help minimize the energy consumed during transport and installation, as well as improve the performance of the energy storage system itself. By reducing the weight, manufacturers can optimize the energy density and storage capabilities of the system.

Furthermore, the aesthetic aspect of energy storage solutions is equally important. Sheet metal allows for intricate designs that can enhance the visual appeal of the chassis. Whether through powder coating, surface finishing, or the use of various colors, manufacturers can create energy storage solutions that align with modern aesthetic sensibilities while providing essential functionality. The ability to adapt the appearance of the chassis through advanced sheet metal processing techniques is a significant driver of consumer acceptance and integration in residential or commercial settings.

2. COMMON TYPES OF SHEET METAL PARTS

In the realm of energy storage chassis, several specific types of sheet metal components are prevalent, each serving different functions and purposes. Common elements include enclosures, mounting brackets, and structural supports, which all play vital roles in the framework of the system. Enclosures are essential for protecting internal components from environmental factors, which could otherwise compromise their functionality or safety. These enclosures must be expertly designed not only to safeguard electrical components but also to facilitate airflow, providing adequate cooling when the system is operational.

Mounting brackets serve an equally critical purpose, allowing for the secure installation of batteries and other key devices within the chassis. These brackets must be robust enough to handle vibrations and shocks that may occur during operation or transport, thus ensuring that all internal components remain securely in place. The precision engineering of these brackets is paramount, as inadequate mounting can lead to mechanical failures, posing severe risks to both the equipment and the environment.

Structural supports, another common type of sheet metal part, reinforce the chassis itself. These support structures maintain the integrity of the enclosure and mitigate the risk of deformation under load. By distributing stress evenly across the chassis, these supports minimize any local weaknesses that could result from significant operational demands. A well-designed system incorporating adequate structural supports can significantly enhance service life and operational performance.

3. MATERIAL SELECTION FOR SHEET METAL PARTS

When selecting materials for sheet metal components in energy storage chassis, several factors must be considered. The choice between aluminum, steel, or specialized alloys greatly influences the final product’s performance, durability, and cost-effectiveness. Aluminum, for example, is often favored for its lightweight properties and excellent corrosion resistance, making it an excellent option for mobile applications. It can enhance energy efficiency by lowering the overall weight of the chassis.

On the other hand, steel remains a popular choice due to its superior strength and lower cost. While heavier than aluminum, steel provides unparalleled protection against physical impacts and environmental stressors. However, those responsible for chassis design must consider galvanization or other protective treatments for steel components to prevent corrosion over time. This treatment is especially important for applications where chassis components will be exposed to moisture or corrosive agents.

Another crucial consideration in material selection is thermal management. Materials with excellent thermal conductivity ensure that heat generated by energy storage systems is effectively dissipated. This characteristic is vital for maintaining optimal operating temperatures and preventing overheating, which can lead to degraded performance or safety hazards. Designers must consider the thermal properties of the chosen metals and their coatings, optimizing heat dissipation while ensuring mechanical stability.

4. MANUFACTURING TECHNIQUES

The methods employed in fabricating sheet metal components profoundly affect their characteristics and the overall quality of the energy storage chassis. Techniques such as laser cutting, forming, bending, and stamping each contribute unique advantages to the manufacturing process. Laser cutting, for example, offers high precision and reduces material waste, while forming techniques help shape the material into desired configurations without compromising structural integrity.

Another vital aspect of manufacturing is the assembly process for various parts. High-quality welding techniques are critical for joining components, ensuring that the chassis not only functions efficiently but is also resilient. Meticulous attention to detail during assembly guarantees that all joints can withstand operational stresses and environmental challenges—often a vital aspect of ensuring the system’s longevity and reliability.

Additionally, the integration of modern technologies such as computer numerical control (CNC) and robotics can enhance the efficiency and accuracy of producing sheet metal parts. These advancements enable manufacturers to produce high volumes of complex components swiftly and accurately, allowing for greater consistency in production. By adopting these innovations, manufacturers can push the boundaries of what is possible in sheet metal design and fabrication, leading to increasingly sophisticated energy storage systems.

5. STRATEGIC DESIGN CONSIDERATIONS

To maximize the effectiveness of sheet metal parts in energy storage chassis, strategic design considerations must be implemented. Effective thermal management solutions must be integrated to dissipate heat generated during operation. Designs should include provisions for airflow and heat exchange, such as ventilation holes, channeling systems, or even combined thermal management solutions utilizing thermal pads.

Additionally, the layout of internal components must be designed with an eye toward accessibility for maintenance and repair. Factors such as the modular design of internal batteries, ease of access to wiring, and straightforward disassembly are critical. These design innovations improve long-term serviceability while ensuring that components can be replaced with minimal downtime.

By contemplating not only performance but also user experience, designers can create energy storage solutions that meet consumer expectations and thrive in real-world operational conditions. The blend of functionality and user-centric design ultimately dictates the success of the energy storage chassis in the competitive market landscape.

6. EMERGING TRENDS IN SHEET METAL DESIGN

The evolution of energy storage solutions is naturally accompanied by advancements in sheet metal design. Emerging trends include the adoption of sustainable materials and eco-friendly manufacturing practices. As environmental concerns gain traction, manufacturers increasingly seek to reduce their carbon footprint by using recycled metals and optimizing production processes to minimize waste. Sustainable practices attract eco-conscious consumers and often lead to cost savings for manufacturers.

Another noteworthy trend involves the adoption of smart technology within sheet metal designs. Integration of sensors and IoT devices into chassis components can provide real-time monitoring of performance and structural integrity, allowing for proactive maintenance and operational efficiency. These advancements demonstrate how traditional sheet metal design can adapt to modern technological landscapes, providing added value to energy storage solutions and solidifying their place within smart energy infrastructures.

FAQs

WHAT IS THE IMPORTANCE OF SHEET METAL PARTS IN ENERGY STORAGE CHASSIS?

The significance of sheet metal parts in energy storage chassis lies primarily in their ability to provide structural support while housing sensitive electrical systems. These components shield internal mechanisms from environmental factors, enhancing durability and reliability. Furthermore, the lightweight characteristic of sheet metal aids in energy efficiency during transportation and installation. Each part, from enclosures to mounting brackets, plays a crucial role in ensuring the system operates optimally, withstands physical stresses, and maintains safety standards. The precision and adaptability of the materials ensure that the energy storage solutions align with modern requirements.

HOW DO MATERIALS AFFECT THE PERFORMANCE OF SHEET METAL PARTS?

The materials selected for sheet metal components significantly influence an energy storage chassis’s performance, cost, and longevity. Aluminum, for instance, offers lightweight and corrosion-resistant qualities, making it suitable for mobile applications. Conversely, steel provides superior strength at a lower cost but may require additional protective treatments against corrosion. Additionally, materials with good thermal conductivity are vital for effective heat dissipation, ensuring the system operates within safe temperature ranges. Ultimately, the choice of materials directly impacts the durability, efficiency, and overall effectiveness of energy storage systems.

WHAT MODERN MANUFACTURING TECHNIQUES ARE USED FOR SHEET METAL PARTS?

Modern manufacturing methods for producing sheet metal parts include techniques such as laser cutting, CNC machining, and advanced welding processes. These techniques enhance precision, reduce material waste, and bolster the structural integrity of components. Furthermore, the incorporation of automation and robotics streamlines production, ensuring high-volume output with consistent quality. By leveraging these contemporary manufacturing advancements, producers can realize innovative designs and adapt swiftly to market demands, leading to enhanced performance and reliability of energy storage chassis.

In summary, delving into the intricacies of sheet metal components within energy storage chassis reveals not only their structural importance but also their multifaceted role in enhancing performance, efficiency, and aesthetics. A thoughtful exploration of material selection, manufacturing techniques, and design considerations underpins every successful implementation of energy storage solutions. From the assessment of durability under varying environmental conditions to the integration of modern smart technologies, these components illustrate a growing adaptation to the evolving demands of energy systems. By ensuring that these metal parts are crafted with precision and care, manufacturers can significantly improve the longevity and efficiency of energy storage solutions, thereby contributing to a sustainable energy future that meets modern needs and expectations. Ultimately, the sheet metal parts of energy storage chassis serve as foundational pillars in the broader context of energy management and utilization strategies, underscoring their significance in our transition toward effective, sustainable energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-sheet-metal-parts-of-energy-storage-chassis/