Nanxiong energy storage fire protection manufacturers encompass companies that specialize in producing advanced fire safety solutions specifically tailored for energy storage systems, particularly lithium-ion batteries. 1. These manufacturers combine innovation with safety protocols, ensuring compliance with national and international standards, 2. Their products include fire-resistant materials, advanced suppression systems, and monitoring technologies designed to preemptively address potential hazards, 3. Manufacturers are increasingly focusing on sustainable practices, aiming to harmonize energy storage benefits with environmental safety, 4. The Nanxiong region is notable for its emphasis on integrating high-tech advancements to improve safety measures in energy storage infrastructure. The demand for reliable fire protection is critical as energy storage capacities continue to expand.

1. UNDERSTANDING ENERGY STORAGE SYSTEMS

In the contemporary energy landscape, energy storage systems play a vital role in stabilizing supply and demand dynamics. The increasing adoption of renewable energy sources has necessitated the development of efficient storage solutions that can accommodate fluctuating energy outputs. Traditional energy generation methods, such as fossil fuels, face significant challenges in providing consistency. As a result, lithium-ion batteries have emerged as the predominant technology for energy storage, offering numerous advantages such as high energy density, modularity, and scalability.

However, with the adoption of lithium-ion technology also comes a series of critical safety concerns. When tasked with storing significant quantities of energy, these systems can pose fire risks, primarily due to overheating, thermal runaway, and external impacts. As a response to these challenges, manufacturers in the Nanxiong region are spearheading the innovation of fire protection technologies specifically designed for energy storage applications. This enables systems to operate with heightened safety while mitigating risks associated with lithium-ion battery failures, thus promoting broader acceptance and integration of energy storage solutions in various sectors.

2. NANXIONG’S MANUFACTURING LANDSCAPE

Nanxiong has earned recognition as a hub for manufacturing in various industries, particularly in energy storage solutions. The region boasts a concentrated ecosystem of companies dedicated to advancing fire protection technologies for energy storage systems. These manufacturers are not only equipped with cutting-edge equipment and technologies but also have access to a skilled workforce well-versed in electrical and safety engineering.

The local manufacturing landscape is characterized by collaboration between various stakeholders, including government institutions, research organizations, and private companies. This collaborative environment fosters innovation and accelerates the development of sophisticated fire protection systems. Manufacturers engage in research and development projects focused on integrating materials science and engineering to create advanced fire-resistant materials and suppression systems.

Furthermore, Nanxiong’s strategic location allows for efficient logistics and supply chain management, facilitating the rapid distribution of fire protection solutions to the larger energy storage industry. The interplay of various participants in this localized network ultimately translates into innovative products that effectively tackle safety challenges associated with energy storage technology.

3. INNOVATIONS IN FIRE PROTECTION TECHNOLOGIES

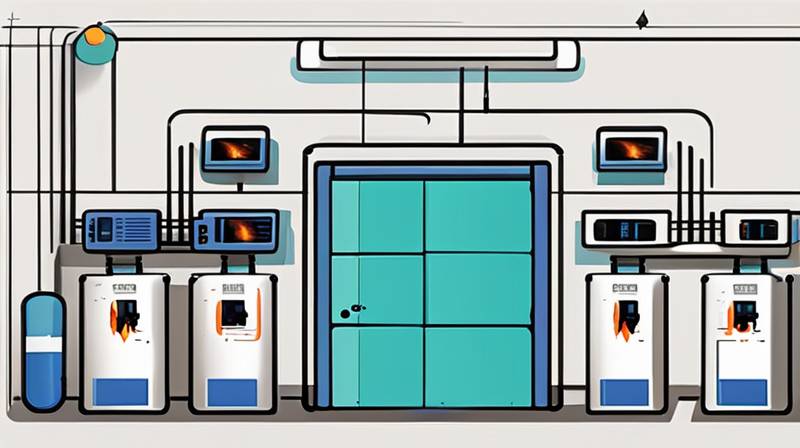

As the energy storage sector evolves, manufacturers in the Nanxiong region are continuously innovating to improve fire protection methodologies. Advancements in materials science have led to the development of fire-resistant enclosures and insulating materials that significantly reduce the risk of thermal runaway. These materials are engineered to withstand high temperatures, preventing the transfer of heat to adjacent cells and minimizing the potential for catastrophic failures.

Additionally, sophisticated suppression systems have emerged as commonplace within energy storage facilities. These systems utilize a range of materials and technologies to extinguish flames in the early stages of a fire, thereby safeguarding both human resources and assets. Rodent and pesticide barriers are also essential components of energy storage design, as they help to mitigate fire risk from uncontrolled pest infestations, which can lead to the deterioration of insulating materials or wiring.

The integration of smart monitoring technologies has further enhanced fire protection measures. Advanced systems utilize sensors and software to continually assess the condition of battery cells, detecting signs of overheating or failure before they escalate. By leveraging data analytics and machine learning, these technologies provide early alerts to facility operators, allowing them to act swiftly in response to any anomalies.

4. REGULATORY LANDSCAPE AND STANDARDS COMPLIANCE

Manufacturers in Nanxiong must navigate a complex environment of regulations and standards designed to uphold safety in energy storage systems. Local and international governing bodies impose a variety of requirements to ensure that energy storage solutions comply with fire safety regulations. These regulations not only validate the efficacy of fire protection measures but also cater to increasingly stringent environmental and sustainability mandates.

In this regard, compliance encompasses various facets, including the selection of materials, system architecture, and operational safety protocols. Manufacturers collaborate with regulatory agencies to establish safety guidelines and standards that align with global practices. This collaboration is critical in maintaining a competitive edge in the energy storage market while ensuring that products meet or exceed safety expectations.

Moreover, ongoing training initiatives for manufacturing personnel are essential, as they familiarize staff with the latest codes and compliance requirements. By promoting a culture of safety and compliance, manufacturers strengthen their reputation and instill confidence among clients and investors in the increasingly critical energy storage domain.

5. SUSTAINABILITY AND ENVIRONMENTAL CONSIDERATIONS

The need for sustainable practices is ever-increasing within the manufacturing sector, and Nanxiong’s energy storage fire protection manufacturers are at the forefront of this effort. Transitioning toward eco-friendly production processes minimizes the environmental impact associated with manufacturing fire safety solutions. This emphasis on sustainability manifests through the choice of materials, energy-efficient manufacturing practices, and end-of-life considerations for products.

Efforts have been made to utilize sustainable materials in the production of fire protection equipment for energy storage systems. The adoption of recyclable or biodegradable materials enhances the overall sustainability quotient of these products, resulting in reduced environmental impact. This forward-thinking approach not only aligns with global sustainability goals but also caters to an increasingly environmentally-conscious consumer base.

Furthermore, manufacturers are also exploring avenues to reduce waste generation during the production process. By implementing lean manufacturing principles, companies can streamline operations, eliminate unnecessary steps, and optimize resource utilization. These principles contribute to a smaller carbon footprint while maintaining high quality and safety standards.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE KEY SAFETY CONCERNS OF ENERGY STORAGE SYSTEMS?

Safety concerns associated with energy storage systems predominantly revolve around thermal runaway, electrical failures, and external hazards. Thermal runaway occurs when a battery cell overheats due to internal short circuits or exposure to environmental factors, subsequently triggering a chain reaction that leads to combustion. The risk is particularly heightened in lithium-ion batteries, which, if not properly managed, can lead to catastrophic outcomes.

Electrical failures can stem from faulty wiring or component malfunctions, potentially resulting in explosions or fires. Furthermore, external hazards, such as environmental conditions, mechanical damage, or human factors during installation and maintenance, necessitate rigorous safety measures to prevent incidents. Consequently, manufacturers focus on integrating robust safety protocols, advanced monitoring systems, and high-performance fire prevention technologies in their design frameworks. Regular inspection and certification of these systems are also critical to maintaining safety standards throughout the life cycle of energy storage facilities.

HOW DO NANXIONG MANUFACTURERS ENSURE COMPLIANCE WITH SAFETY STANDARDS?

Manufacturers in Nanxiong prioritize compliance with safety standards by collaborating closely with local and international regulatory bodies. Regular audits and inspections are conducted to assess adherence to established safety protocols. This proactive approach ensures that products are continuously aligned with the latest regulations and industry best practices.

Additionally, manufacturers invest significantly in research and development to stay ahead of evolving safety standards. As new regulations emerge, companies adjust their manufacturing processes, technologies, and materials accordingly. This adaptability not only guarantees compliance but also cultivates an environment of continuous improvement, enhancing the overall quality and safety of fire protection solutions.

Training and certification programs for production personnel play a vital role in ensuring compliance as well. Staff members are educated on the latest safety protocols, standards, and best practices, equipping them with necessary knowledge to maintain compliance throughout production. This ongoing focus on education and training reinforces the commitment to safety, ensuring that all stakeholders are well-prepared to meet and exceed regulatory expectations.

WHAT ROLE DOES INNOVATION PLAY IN FIRE PROTECTION?

Innovation is a cornerstone of effective fire protection solutions for energy storage systems. The rapidly evolving nature of technology presents opportunities to develop cutting-edge materials and systems that enhance fire safety. Manufacturers are compelled to continually innovate to address emerging challenges in energy storage safety.

Advanced materials have been developed to improve fire resistance, prevent thermal runaway, and provide enhanced durability. Furthermore, incorporating smart technology into fire protection systems allows for real-time monitoring and rapid response to potential hazards. Such innovations have become indispensable in maintaining the safety and reliability of energy storage systems. The emphasis on innovative approaches underscores the vital relationship between technology advancement and the continuous improvement of safety measures within energy storage infrastructure.

In summation, the significance of Nanxiong energy storage fire protection manufacturers cannot be overstated. They stand at the forefront of addressing the safety challenges posed by energy storage systems, particularly as reliance on renewable energy sources expands. Their commitment to innovation, regulatory compliance, and sustainability has led to the development of sophisticated fire protection solutions that not only safeguard energy storage facilities but also promote broader acceptance and integration of energy storage technologies within various sectors. Through close collaboration with regulatory bodies and a focus on continuous improvement, these manufacturers pave the way for safer energy futures. As the landscape of energy generation continues to evolve, the ongoing commitment of Nanxiong manufacturers to fire safety will play an integral role in powering the transition toward a sustainable energy paradigm.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-nanxiong-energy-storage-fire-protection-manufacturers/