1. Radial Flow Packed-Bed Thermal Energy Storage (KTH, Sweden)

- Researchers at KTH have developed a radial flow packed-bed TES system using hot air and solid materials like pebbles or copper slags as thermal storage media.

- This design achieves over 90% thermal efficiency and stores heat at temperatures up to 800°C.

- It reduces pressure drops by about half compared to traditional axial flow packed-beds, enhancing performance and lowering operational losses.

- The system facilitates effective heat transfer and storage in CAES by combining hot air circulation with packed solid materials, aiming for commercialization soon.

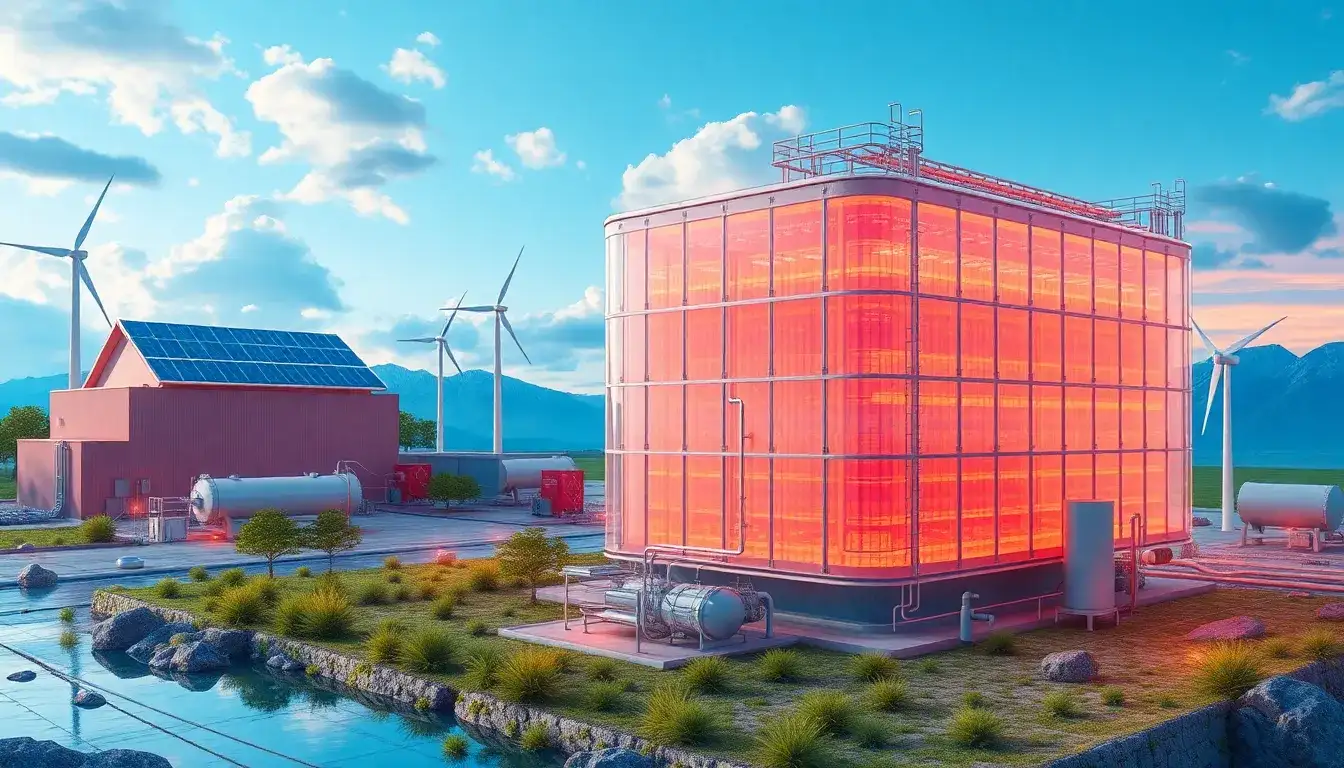

2. Pumped Thermal Energy Storage (PTES) by Synchrostor (UK Startup)

- Synchrostor has patented a novel PTES system that integrates a multi-cylinder compressor-expander machine operating at high pressure.

- During charging, electricity runs the compressor, pressurizing and heating an operating gas, which heats a thermal storage material in a heat exchanger.

- The heated material is stored in an insulated silo at atmospheric pressure, optimizing thermal storage stability.

- PTES also includes a cold storage silo to capture low-temperature energy, improving overall cycle efficiency.

- This approach uses abundant, non-strategic local materials, enabling scalable and sustainable deployment without reliance on rare resources.

- It addresses grid stability and variable power demand challenges with flexibility and large-scale thermal storage capabilities.

3. Electrically Conductive Firebrick by Electrified Thermal Solutions

- A scalable and cost-effective TES innovation involves electrically conductive firebricks capable of storing heat without embedded wires.

- These firebricks enable storage of high-temperature heat efficiently for industrial heating processes.

- Such materials can be integrated with CAES systems to provide stored thermal energy for process heating in industries like cement or iron manufacturing, which are typically difficult to decarbonize.

- This innovation contributes to reducing costs and increasing the feasibility of TES in industrial and energy storage applications.

4. Broader Trends and Applications

- TES innovations increasingly target decarbonizing hard-to-electrify sectors by offering clean heat storage solutions.

- Technologies that combine thermal storage with compressed air systems enable more efficient, resilient, and scalable energy storage.

- Advanced TES can capture and reuse heat released during air compression in CAES, significantly enhancing overall system efficiency and reducing fossil fuel reliance.

Summary Table of Key Innovations

| Innovation | Description | Benefits |

|---|---|---|

| Radial flow packed-bed TES (KTH) | Uses hot air and pebbles/copper slags for >90% efficient heat storage at ~800°C | High efficiency, reduced pressure drop, scalable |

| Pumped Thermal Energy Storage (Synchrostor) | High-pressure compressor-expander cycle with hot and cold thermal silos | Grid stability, uses abundant materials, scalable |

| Electrically Conductive Firebrick (ETS) | Firebrick storing heat without wires for industrial heat | Cost-effective, scalable, supports industrial decarbonization |

| Integration of TES in CAES | Using heat storage to capture compression heat and supply thermal energy | Increases CAES efficiency, reduces fossil fuel consumption |

These innovations collectively represent the frontier of thermal energy storage integrated with CAES, enabling cleaner, more efficient, and economically viable large-scale energy storage solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-most-innovative-thermal-energy-storage-solutions-for-caes/