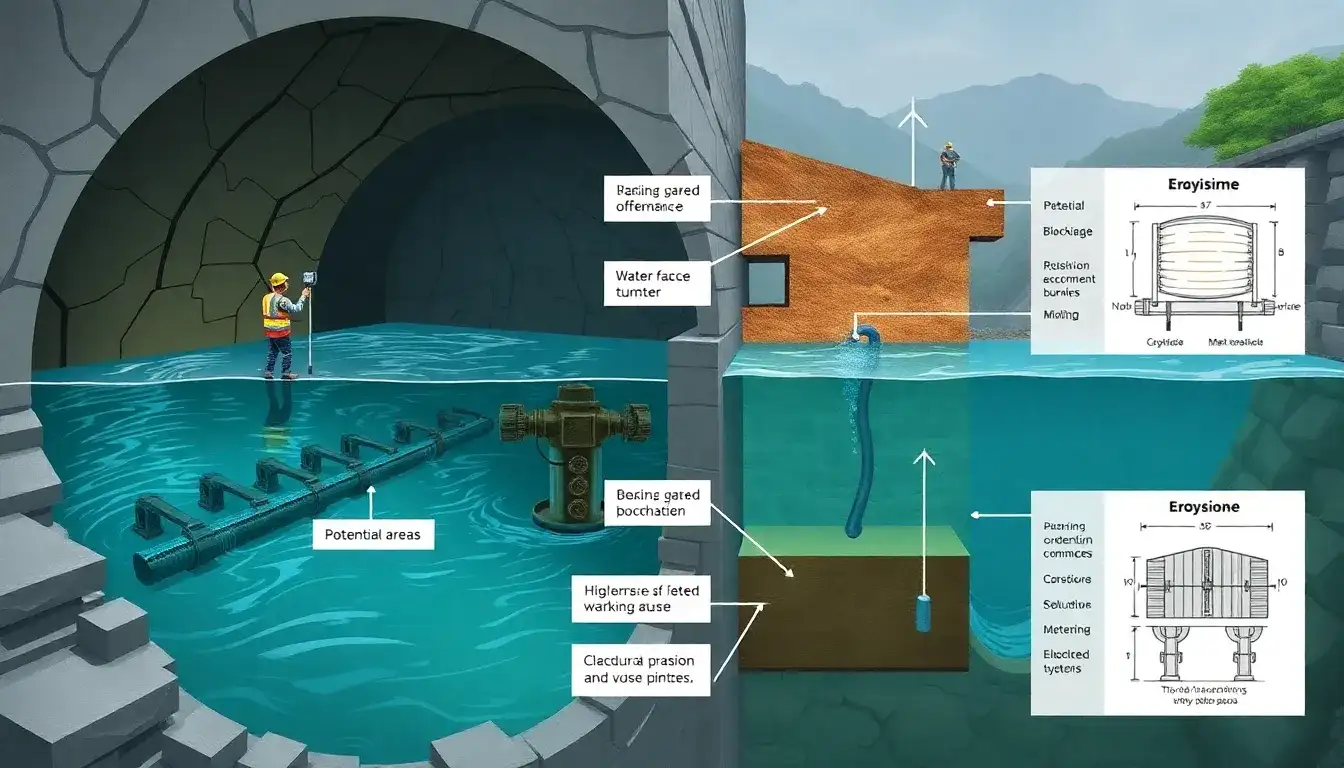

The most common issues with tunnel maintenance in pumped hydro storage plants primarily involve challenges related to sedimentation, erosion, and mechanical damage caused by transported debris. Key problems include:

- Erosion and sediment transport: Changes in sediment load, such as increased sand, gravel, or small rocks carried through the tunnels, can cause significant damage to turbines and other equipment, leading to prolonged stoppages for repair. Erosion within tunnels due to abrasive sediments is a critical maintenance issue.

- Ineffective sand traps: Sand traps are installed upstream of penstocks to reduce sediment loads by slowing flow velocity and allowing heavier particles to settle. However, if these traps are under-designed or fail to operate correctly due to flow variability or increased velocities, sediments may continue downstream, causing damage.

- Flow variability and environmental effects: Variations in flow, including potential ice formation or fluctuating discharge rates at tailraces, can complicate tunnel maintenance and impact aquatic ecosystems. These issues add complexity to operational management and maintenance scheduling.

- Unknown or challenging ground conditions: Tunnel excavation and maintenance can be hindered by unexpected geological conditions, groundwater presence, or structural stresses, which affect both the cost and the feasibility of ongoing maintenance work.

- Corrosion and wear: Given the underground and wet environment, corrosion of tunnel structures and associated components is a persistent challenge, demanding continuous inspection and maintenance to avoid failures.

- High maintenance costs and logistical complexity: The extensive tunneling and underground infrastructure require specialized techniques and equipment for access, inspection, repair, and sediment management, which contribute to high maintenance costs and operational downtime.

In summary, tunnel maintenance issues in pumped hydro storage are dominated by sediment-induced damage, erosion control challenges, ensuring effective sediment traps, coping with variable hydraulic conditions, addressing geological uncertainties, and managing corrosion and operational costs. These factors necessitate ongoing monitoring, predictive tools for sediment behavior, and robust design and maintenance strategies to sustain safe and efficient plant operation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-most-common-issues-with-tunnel-maintenance-in-pumped-hydro-storage/