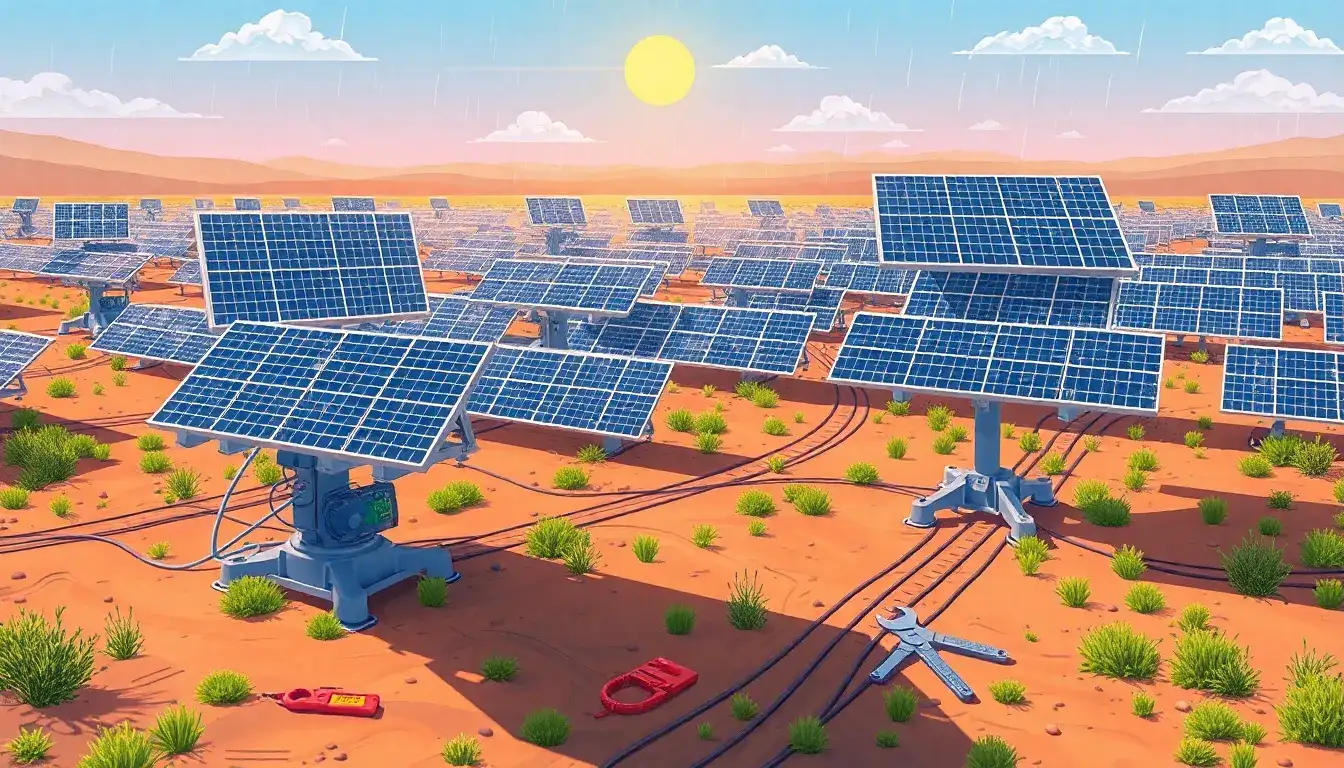

Common Issues Requiring Maintenance in Solar Trackers

1. Mechanical Wear and Tear

Solar trackers have moving parts such as motors, gears, and bearings that enable panel movement to follow the sun. These components are subject to wear over time due to constant motion and exposure to the elements. Regular inspection and lubrication of these mechanical parts are necessary to prevent failures or reduced tracking accuracy.

2. Electrical Connection Problems

Loose terminals and under-torqued lugs that hold wiring connections can lead to poor electrical contact and failures. Pinched wires or damaged conduits protecting wiring are also common issues that cause electrical faults. Regular checks to ensure all connections are secure and conduits intact are vital to avoid system downtime.

3. Motor and Drive Failures

The servo motors or actuators that move the tracker panels often face issues such as overheating, power supply problems, or mechanical jams. These can be caused by improper power sourcing or control signal issues, for example powering servos incorrectly from microcontroller power sources can damage components.

4. Environmental Debris and Pest Infestation

Dust, pollen, leaves, and bird droppings accumulate on solar panels, reducing their efficiency. Similarly, pests like squirrels can chew on wires or nest in tracker assemblies, causing physical and electrical damage. Cleaning the panels regularly and installing deterrents like bird spikes or mesh can mitigate these problems.

5. Sensor and Communication Failures

Trackers rely on light sensors or algorithms to orient panels correctly. Faulty light sensors due to dirt or damage, as well as communication issues between the tracker controller and the motor/drive system, can lead to incorrect positioning or failure to track the sun effectively.

6. Structural Issues and Corrosion

Trackers exposed to weather can develop corrosion in joints or supports, affecting structural integrity and alignment precision. Routine visual inspections for corrosion, misalignment, or frame damage are important maintenance steps.

Summary Table of Common Solar Tracker Maintenance Issues

| Issue Type | Description | Maintenance Action |

|---|---|---|

| Mechanical Wear | Wear on motors, gears, bearings | Lubricate, inspect, replace worn parts |

| Electrical Connections | Loose terminals, pinched wires, leaking conduits | Tighten, repair wiring and conduits |

| Motor/Drive Failures | Motor damage due to power issues or jams | Check power source, replace faulty motors |

| Environmental Debris/Pests | Dust, bird droppings, pests causing damage | Clean panels, install deterrents |

| Sensor/Communication Issues | Faulty sensors or signal loss affecting tracking | Clean sensors, check control wiring |

| Structural/Corrosion Issues | Frame corrosion or mechanical misalignment | Inspect and repair structural components |

Maintaining solar trackers requires a multidisciplinary approach addressing mechanical, electrical, and environmental factors to ensure optimal performance and longevity. Regular inspections, cleaning, tightening electrical connections, and timely repairs are key preventive maintenance measures.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-most-common-issues-that-require-maintenance-in-solar-trackers/