1. Various materials, including metals, polymers, and composites, are utilized in the production of energy storage sheet metal components, 2. Key attributes such as weight, conductivity, and durability impact the selection of materials, 3. Metals like aluminum and copper are favored due to their high conductivity, 4. Polymers add versatility and corrosion resistance, making them useful in specific applications, 5. Composite materials enhance strength-to-weight ratios, vital for advanced energy solutions. Among these, metals lead in conductance, playing a crucial role in efficiency and reliability. This article explores the significance of material choice in energy storage systems, contributing to technological advances and sustainability efforts.

1. MATERIALS IN ENERGY STORAGE SHEET METAL PARTS

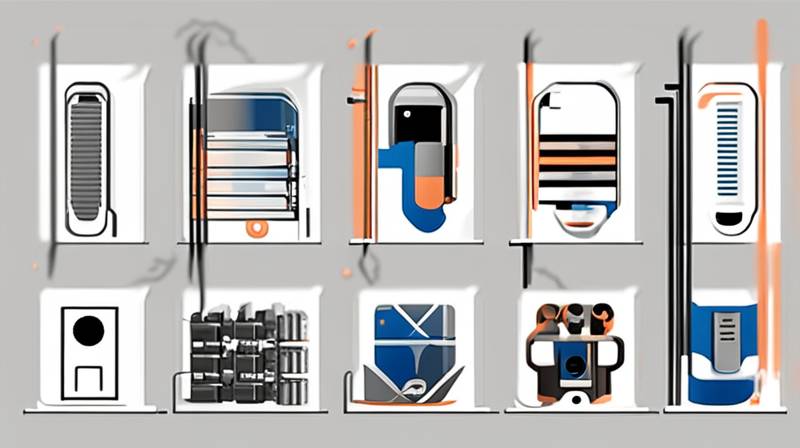

The realm of energy storage comprises a plethora of technologies, each requiring specialized materials to optimize performance. Energy storage systems, such as batteries and capacitors, often rely on sheet metal parts for housing, connections, and support structures. These parts are essential in maintaining the integrity and functionality of the energy storage units. In a landscape striving for efficiency, the choice of materials is pivotal, shaping everything from energy density to lifespan.

When selecting materials for energy storage applications, several factors come into play, including conductivity, mechanical strength, weight, and thermal stability. Each material brings unique attributes that can either enhance or hinder the overall performance of the energy storage system. Furthermore, evolving technologies and environmental concerns necessitate continuous advancements in material science. This dynamic has led to novel approaches in fabricating energy storage components that are not only efficient but also eco-friendly.

2. METALS: ALUMINUM AND COPPER

Metals are at the forefront of energy storage technology due to their superior electrical conductivity and mechanical durability. Among the various metals, aluminum and copper have emerged as the go-to choices for manufacturers in this field. The lightweight nature of aluminum makes it particularly appealing for applications where minimizing weight is crucial, while still offering a commendable balance between cost and performance. Aluminum’s resistance to corrosion also enhances its lifespan, a desirable characteristic in applications exposed to variable weather conditions.

Conversely, copper’s unparalleled conductivity renders it an essential component in battery and capacitor designs. Utilizing copper in wiring and connections ensures minimal power losses, enabling systems to operate at optimal efficiency. However, manufacturers must carefully consider the cost implications since copper tends to be significantly more expensive than aluminum. This financial aspect can influence material choice, especially in large-scale productions or budget-sensitive projects.

3. POLYMER COMPOSITIONS IN ENERGY STORAGE

While metals dominate the energy storage landscape, polymers have carved out their niche, particularly in specific applications that require unique properties. Polymers, such as polyethylene and polypropylene, have gained traction in energy storage systems due to their lightweight and versatile characteristics. Their ability to be molded into various shapes allows for innovative design solutions that can better cater to specific energy storage needs. Moreover, polymers exhibit excellent corrosion resistance, providing a significant advantage in harsh operational environments.

In recent years, researchers have explored the integration of conductive polymers, which combine the beneficial properties of both conductive materials and polymers. These materials can potentially reduce weight while retaining some level of conductivity. This fusion addresses the challenges posed by traditional materials in creating lightweight energy storage solutions, appealing to modern demands for efficiency and versatility.

4. COMPOSITES: ADVANCED MATERIALS FOR ENERGY APPLICATIONS

The development of composite materials signifies a remarkable advancement in material science, particularly for applications demanding a combination of properties not found in solitary materials. Composites typically comprise a matrix material, such as a polymer or resin, reinforced with fibers or particles like carbon or glass fibers. This combination results in enhanced mechanical strength and durability, making composites a popular choice in high-performance energy storage applications.

The biggest advantage of composited materials is the customizable nature of their properties. Engineers can tailor the composite’s weight, stiffness, and thermal resistance, among other factors, to meet specific performance criteria. This flexibility allows manufacturers to create energy storage components that are not only lightweight but also exceptionally strong. The ongoing research into smart composites—materials that can adapt or change properties in response to their environment—holds substantial promise for future energy storage innovations.

5. INFLUENCE OF MATERIAL SELECTION ON PERFORMANCE

The performance of energy storage systems is heavily influenced by the materials utilized in their construction. Material selection impacts efficiency, longevity, and cost-effectiveness, which are fundamental factors for both manufacturers and end-users. As competition heightens and sustainability becomes more critical, the demand for advanced materials that can provide superior performance while being environmentally friendly intensifies.

Additionally, technological advancements intrinsic to material science contribute significantly to the evolution of energy storage technologies. Every incremental improvement in material properties can lead to exponential enhancements in system performance. Therefore, the industry must not only focus on immediate material benefits but also consider long-term sustainability and recyclability of these materials, ensuring that energy storage solutions align with global environmental goals and standards.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE DIFFERENT TYPES OF MATERIALS USED IN ENERGY STORAGE SHEET METAL PARTS?

In the construction of energy storage sheet metal components, a variety of materials are employed, each chosen based on specific functional requirements. The prominent categories include metals, polymers, and composites. Metals, notably aluminum and copper, are favored for their exceptional electrical and thermal conductivity, alongside mechanical durability. These metals facilitate efficient electron flow and thermal management in systems like batteries and capacitors.

On the other hand, polymers such as polyethylene and polypropylene are often selected for lightweight applications requiring flexibility and corrosion resistance. They find use in numerous configurations within energy systems, offering benefits in both longevity and manufacturing ease. Moreover, composite materials, which combine polymers with reinforcing elements, are pioneering structural applications by permitting customization of mechanical properties.

In summary, the selection of materials hinges on balancing conductivity, weight, and durability with cost pathways, directly impacting the performance and sustainability of energy storage solutions.

HOW DOES MATERIAL SELECTION AFFECT ENERGY STORAGE SYSTEM EFFICIENCY?

The efficiency of energy storage systems is intricately linked to the materials chosen for their construction. Core components, such as electrodes and connectors, require materials with high conductivity to minimize resistive losses when charging or discharging. For instance, utilizing copper in these vital connections allows for faster energy transfer, reducing heat generation and associated losses. The choice of material not only determines how quickly energy can be stored or released but also influences the lifespan of the cells.

Furthermore, factors like thermal stability and mechanical integrity are essential in ensuring reliable operation under varying environmental conditions. Materials that exhibit poor thermal characteristics may compromise performance due to heat build-up, leading to energy losses or catastrophic failure. Consequently, understanding and optimizing how different materials interact within the energy storage unit is vital for enhancing the overall efficiency and longevity of these systems.

WHAT ARE THE SUSTAINABILITY CONCERNS RELATED TO ENERGY STORAGE MATERIALS?

As the world increasingly pivots toward sustainable practices, the materials utilized in energy storage systems come under scrutiny for their ecological impact. The extraction, processing, and disposal of materials such as metals can lead to significant environmental degradation, prompting a search for alternatives that mitigate these impacts. The carbon footprint from mining and refining processes, especially for metals like copper and lithium, raises concerns about sustainability in the energy storage sector.

Additionally, lifecycle analysis is crucial in evaluating how long materials can be utilized effectively. Recyclability of materials plays a significant role in ensuring that energy storage systems are not only efficient during their working life but also responsible post-consumption. The development of biodegradable polymers or closed-loop systems where metals are continuously recycled is gaining momentum to address these concerns. Ensuring that energy storage advances align with ecological responsibilities is now more vital than ever.

A detailed analysis of material options and their implications reveals how thoughtfully chosen materials play a crucial role in optimizing energy storage solutions. Key considerations include conductivity, durability, sustainability, and costs, highlighting a multifaceted approach to material selection. Metals such as aluminum and copper lead the way due to their conductive properties but come with cost and weight considerations. Polymers provide unique advantages in weight and corrosion resistance, while composites offer tailored solutions for high-performance applications. This nuanced understanding of materials provides insights not only into the current energy storage landscape but also into its future trajectory. As technologies continue to evolve, and as sustainability concerns grow, the energy sector must adapt by continually innovating in material science. Achieving a balance between performance, cost-effectiveness, and environmental responsibility will dictate the direction of energy storage advancements, aligning with broader goals of creating efficient, reliable, and sustainable energy systems for the future. Each material choice embodies opportunities for innovation, efficiency, and resilience against the challenges posed by a rapidly changing world. The journey ahead remains intertwined with material advancements, underscoring their integral role in shaping the future of energy storage.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-materials-of-energy-storage-sheet-metal-parts/