Energy storage steel belts are increasingly pivotal in the sectors of renewable energy and power management. 1. Manufacturers play a crucial role in producing innovative technologies that enhance energy efficiency, 2. Key market players include multinational corporations and specialized firms, 3. The manufacturing process is highly technical and requires significant investment in research and development, 4. These manufacturers are at the forefront of addressing the scalability and durability of energy storage solutions. An example of practical application includes the use of energy storage steel belts in converting renewable energy into stable power supplies, crucial for overcoming the intermittent nature of renewable resources.

1. ENERGY STORAGE TECHNOLOGY: AN INTRODUCTION

The evolution of energy storage technologies has gained significant momentum in recent years, primarily driven by the increasing demand for sustainable energy solutions. Energy storage systems, particularly those utilizing steel belts, play a pivotal role in allowing energy harvested from renewable sources, such as solar and wind, to be stored efficiently for later use. Unlike traditional energy systems, which often rely on fossil fuels, modern advancements in technology have made it possible to store energy in a manner that enhances reliability and sustainability. It is essential to comprehend the mechanisms and benefits of steel belt technology within the broader context of energy management.

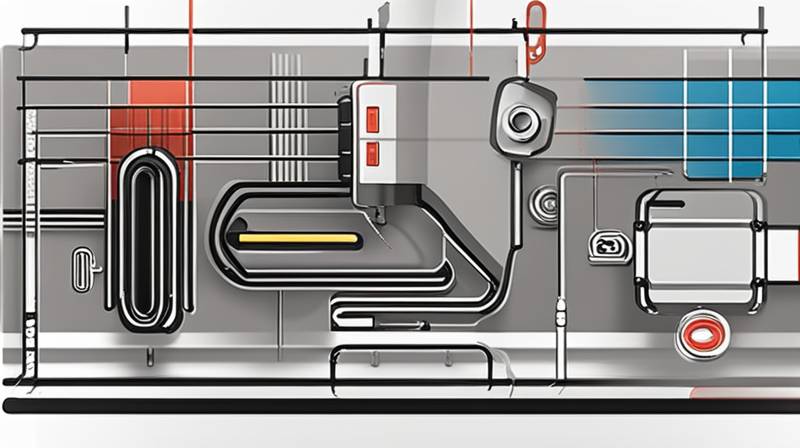

Steel belts serve as the backbone for many contemporary energy storage systems due to their durability and efficiency in managing energy flow between generation and consumption. This technology not only facilitates energy transmission but also acts as a buffer that absorbs fluctuations in energy supply and demand. As renewable energy sources become more prevalent, the need for efficient energy storage solutions becomes even more critical. By evaluating the key players and the technological advancements shaping the landscape of energy storage, one can appreciate the intricate dynamics of this market.

2. MANUFACTURERS OF ENERGY STORAGE STEEL BELTS

When discussing the manufacturers in the niche of energy storage steel belts, it is crucial to highlight several prominent organizations that have established their expertise in this domain. These entities range from renowned multinational companies to specialized startups that focus on niche solutions tailored for varying market needs. Each manufacturer brings unique capabilities and innovations that contribute to the advancement of energy storage technologies.

Some of the major manufacturers include established companies known for their robust industrial solutions. For instance, firms like Siemens, Schneider Electric, and ABB are heavily invested in developing comprehensive energy storage configurations that incorporate steel belt technology. Their experience in large-scale electrical systems positions them well to leverage steel belts in enhancing the efficiency of energy storage. These manufacturers possess the resources to undertake extensive research, ensuring that the steel belts they produce are not only effective but also future-proof, projecting resilience against new technological demands.

On the other end of the spectrum, smaller manufacturers and startups have begun to carve out their niches, focusing on specific applications or innovative production methods for steel belts. By concentrating on areas like cost reduction or improved energy density, these companies can offer specialized solutions. Their commitment to innovation can significantly influence the market, pushing larger competitors to adapt their strategies.

3. THE MANUFACTURING PROCESS OF ENERGY STORAGE STEEL BELTS

Examining the intricacies involved in the manufacturing process of energy storage steel belts reveals a profound complexity that underscores their value. The manufacturing involves high-precision engineering and stringent quality control to ensure that the steel belts can withstand the demanding environment of energy storage systems. The steel used must meet exact specifications for strength and flexibility, enabling the belts to perform effectively over time.

The production process typically begins with the selection of raw materials known for their durability. Steel chosen for energy storage belts must undergo specific treatments to enhance its properties, ensuring it can withstand various thermal and mechanical stresses that may arise during operation. This processing not only improves its performance but also increases the lifespan of the energy storage solution. Manufacturers often engage in rigorous testing protocols to confirm that their belts meet both industry standards and the functional requirements of energy systems.

Furthermore, innovation within the manufacturing process is paramount as technology evolves. Continuous investment in research allows manufacturers to adopt cutting-edge materials and techniques, ensuring competitive advantage in a rapidly changing market. Advanced manufacturing processes—like the integration of automation and robotics—enhance production efficiency while maintaining high quality. As competition intensifies, the ability to innovate in both design and production processes will remain vital for manufacturers of energy storage steel belts.

4. THE ROLE OF ENERGY STORAGE STEEL BELTS IN RENEWABLE ENERGY

Integrating energy storage steel belts within renewable energy systems is crucial for achieving optimal performance and reliability. These belts allow excess energy generated during peak production times to be stored and utilized when demand surpasses supply. This ability to balance the grid is essential for maintaining a stable energy supply, especially as reliance on renewable sources increases.

Furthermore, the strategic use of steel belts can enhance energy conversion efficiencies. They act as efficient conduits for transferring energy between various components of the energy storage system, minimizing losses. Their role in energy storage extends to enhancing the longevity and dependability of battery systems, as they provide mechanical support and protection. With rapid advancements in technology and growing demand for renewable energy, the importance of innovations in energy storage solutions continues to grow.

In addition to technical advantages, the adoption of energy storage belts is also influenced by economic factors. The decreasing costs associated with the production of energy storage systems make them increasingly accessible to consumers and businesses. As the industry moves towards more sustainable practices, manufacturers are expected to adapt their strategies and optimize resource allocation to remain competitive.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON MATERIALS USED IN ENERGY STORAGE STEEL BELTS?

Energy storage steel belts are primarily fabricated from various grades of steel, selected for their strength, flexibility, and resistance to corrosion. Typically, manufacturers may use carbon steel, stainless steel, or alloyed steel, depending on the specific requirements of the application. Carbon steel tends to provide excellent tensile strength and rigidity, making it ideal for situations where structural integrity is paramount. Stainless steel, on the other hand, offers superior resistance to environmental degradation, making it suitable for applications exposed to moisture or corrosive elements. Additionally, manufacturers may incorporate protective coatings to enhance the durability and functionality of the steel belts. Such coatings can further improve their lifespan by preventing corrosion and wear, particularly in challenging operational environments. By utilizing various steels and innovative treatments, manufacturers can tailor energy storage steel belts to meet the evolving demands of modern energy storage solutions effectively.

HOW DO ENERGY STORAGE STEEL BELTS AFFECT ENERGY EFFICIENCY?

The integration of energy storage steel belts plays a crucial role in improving energy efficiency across various renewable energy systems. These belts are designed to facilitate the efficient transfer and storage of energy, ultimately enhancing the overall performance of the energy grid. By acting as a storage medium, steel belts enable excess energy generated during peak production times to be held for use during periods of high demand. This capability minimizes energy loss and provides a buffer that stabilizes energy flow, leading to increased overall system efficiency. Moreover, the mechanical design of energy storage belts allows for rapid energy discharge and replenishment, which is critical for addressing fluctuations in supply and demand. Efficiency extends beyond just the immediate handling of energy; advances in belt material and construction also contribute to reduced operational wear, translating into lower maintenance costs and longer service life for energy storage systems. Manufacturers continue to innovate in this area, seeking new ways to optimize performance and ensure that energy is stored and utilized as effectively as possible.

WHAT ARE THE FUTURE TRENDS IN ENERGY STORAGE STEEL BELT MANUFACTURING?

As the demand for renewable energy solutions continues to surge, the future of energy storage steel belt manufacturing is poised for significant transformation. One major trend likely to shape the industry is the increased focus on sustainability in manufacturing processes. This includes utilizing recycled materials and developing greener production techniques, aligning with global environmental goals. Additionally, advancements in technology will drive innovation in the materials used for steel belts; innovations such as nano-coatings and the use of composites may enhance performance while reducing weight and cost.

Furthermore, the integration of smart technology into energy storage systems is expected to gain traction. This will allow manufacturers to incorporate sensors and advanced monitoring systems within steel belts, providing real-time data to optimize performance and predict maintenance needs. As end-users seek more effective and intelligent solutions, manufacturers will need to pivot towards creating smarter products that add value beyond basic energy storage functions. Embracing these trends will be fundamental for manufacturers seeking a competitive edge in the evolving landscape of energy storage solutions.

Manufacturers of energy storage steel belts are at the forefront of developing solutions that enhance energy efficiency and reliability. The importance of these entities cannot be overstated, as they are crucial for meeting the ever-growing demands of a sustainable energy future. Through innovative manufacturing processes and the adoption of advanced materials, they create products that help to facilitate the transition towards renewable energy sources. Moreover, energy storage steel belts contribute significantly to balancing the energy grid by allowing for efficient energy storage and management, particularly during fluctuations in supply and demand. As the market evolves, manufacturers play a critical role in ensuring that the technology continues to advance, fostering a world that relies more heavily on sustainable practices. In light of these factors, the ongoing development and refinement of energy storage steel belts will be essential not just for market players, but for the global community at large. Companies in this sector must continue to innovate and embrace new technologies to ensure their place in a rapidly changing energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-manufacturers-of-energy-storage-steel-belts/