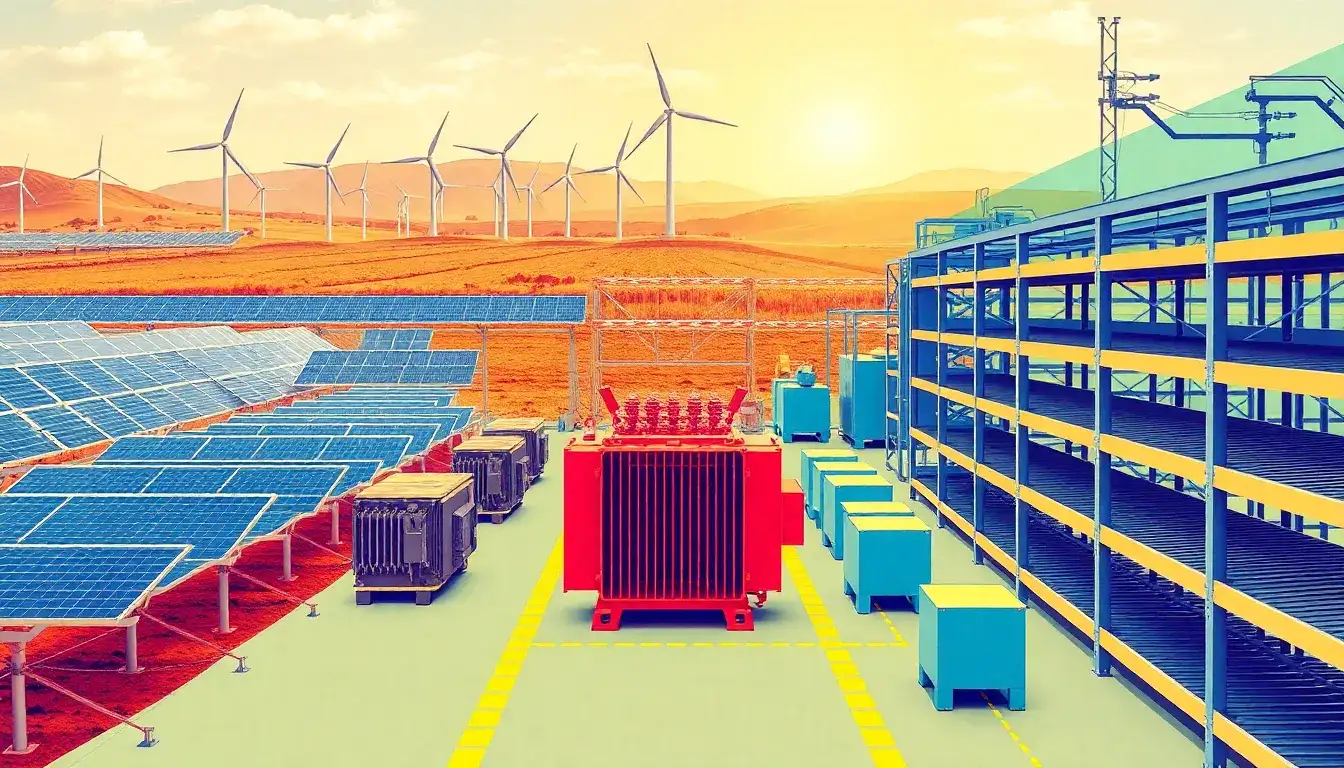

Supply Chain and Material Constraints

Grain-oriented electrical steel (GOES) demand has surged due to competition from electric vehicles, EV chargers, and transformer production. This specialized steel is critical for transformer cores, and global supply chain disruptions—including pandemic backlogs, shipping delays, and geopolitical tensions—have exacerbated shortages.

Rising Electricity Demand

Electrification of transportation, buildings, and industries, combined with data center expansion and renewable integration, has spiked grid load. NREL projects nearly 16% higher transformer demand by 2030, requiring more and larger units. This growth strains manufacturing capacity amid existing lead times of up to three years for new orders.

Production and Labor Challenges

Custom designs dominate the market, limiting standardized manufacturing efficiencies. Simultaneously, labor shortages in skilled manufacturing roles delay production scaling. Combined with raw material scarcity, these factors have driven transformer costs up 400% since 2020.

Policy and Infrastructure Pressures

Extreme weather events (e.g., wildfires, hurricanes) accelerate grid rebuilds, further stressing supply. Without coordinated standardization efforts or strategic reserves, delays in renewable projects—affecting up to 25% globally—will persist.

The convergence of these issues has created a bottleneck, directly slowing clean energy transitions in the U.S. and Europe.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-reasons-for-the-shortage-of-transformers-in-the-renewable-energy-sector/