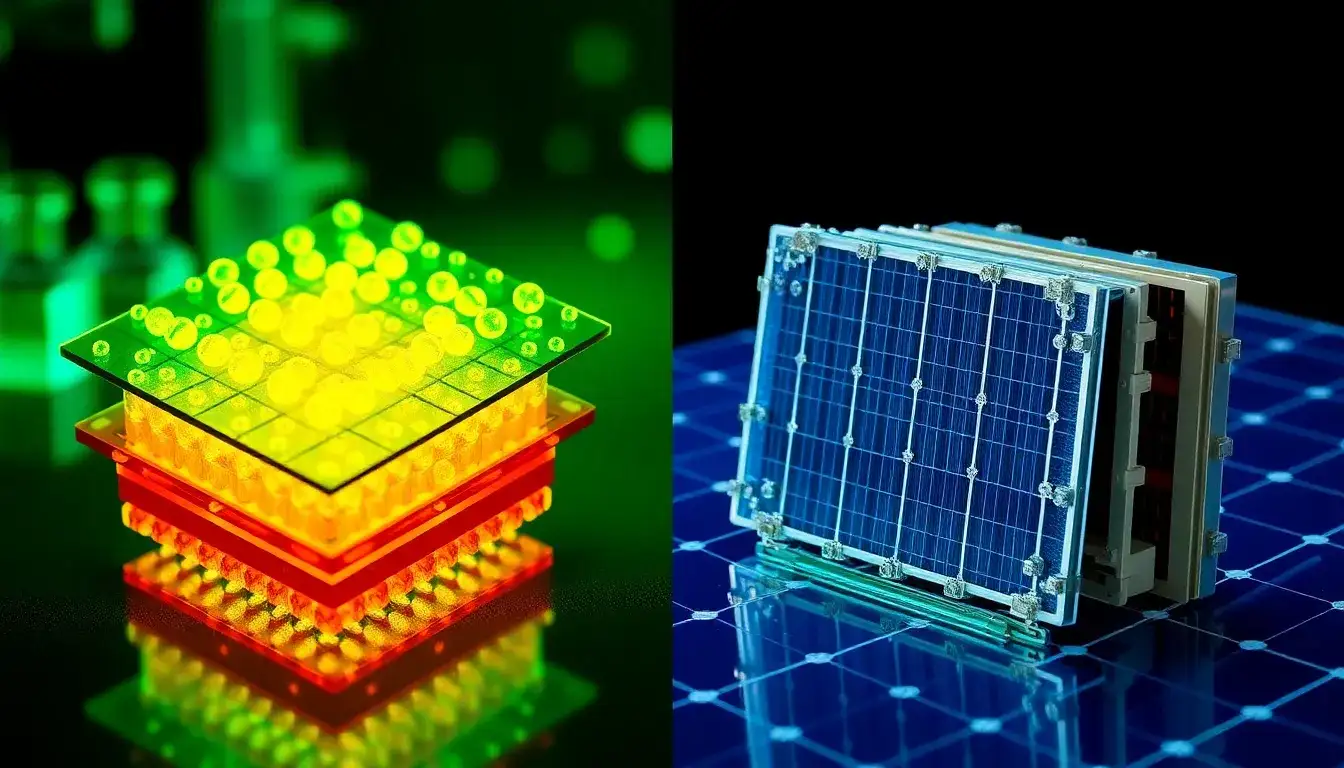

The main materials driving the cost differences between perovskite and silicon solar panels stem from their distinct component needs and manufacturing processes.

Perovskite Solar Panels:

- The primary cost contributors include perovskite precursor inks, which are relatively inexpensive, estimated around $250 USD to cover 1 square meter of surface.

- Additional costs come from solar glass, backsheets, encapsulation materials, and electron transport layer (ETL) precursors used specifically in the perovskite sub-cell of tandem modules.

- Perovskite solar cells benefit from simpler and potentially cheaper materials but currently also require specific processing equipment that contributes to cost.

- The relatively newness of industrial-scale perovskite processing means these costs are expected to decrease significantly as production standardizes.

Silicon Solar Panels:

- Silicon panels typically involve crystalline silicon wafers, which require energy-intensive purification and wafer production processes, historically making them more expensive on a materials and manufacturing basis.

- Silicon solar modules also rely on well-established glass, encapsulation, and backsheet materials, with more mature manufacturing lines driving cost reductions over time.

- The levelized manufacturing cost for silicon panels ranges roughly between $0.34/W and $0.54/W depending on geographic production location.

Comparative Cost Drivers:

| Material/Component | Perovskite Solar Panels | Silicon Solar Panels |

|---|---|---|

| Active Layer Materials | Perovskite precursor inks (low cost but specific) | Purified crystalline silicon wafers (high purification cost) |

| Encapsulation & Module Packaging | Solar glass, backsheets, encapsulation (specific ETL precursors) add to costs | Similar encapsulation and glass materials, well-established supply chain |

| Manufacturing Equipment | Specialized perovskite processing equipment adds to cost | Mature silicon cell manufacturing equipment |

| Module Efficiency Impact | Higher potential efficiencies (25-35%) can lower cost per watt despite material costs | Typical efficiencies around 20-22%, cost stable due to maturity |

In summary, perovskite solar panels currently carry higher costs due to the specialized materials like electron transport layers and processing equipment needed for the perovskite layers, as well as encapsulation requirements in tandem modules. Silicon panels incur costs mainly from the purified silicon wafers and mature production lines. However, perovskite costs are projected to decline sharply with industrial scaling and technology maturation, potentially dropping below silicon in cost per watt as efficiencies improve and materials cost decreases.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-materials-driving-the-cost-differences-between-perovskite-and-silicon-solar-panels/