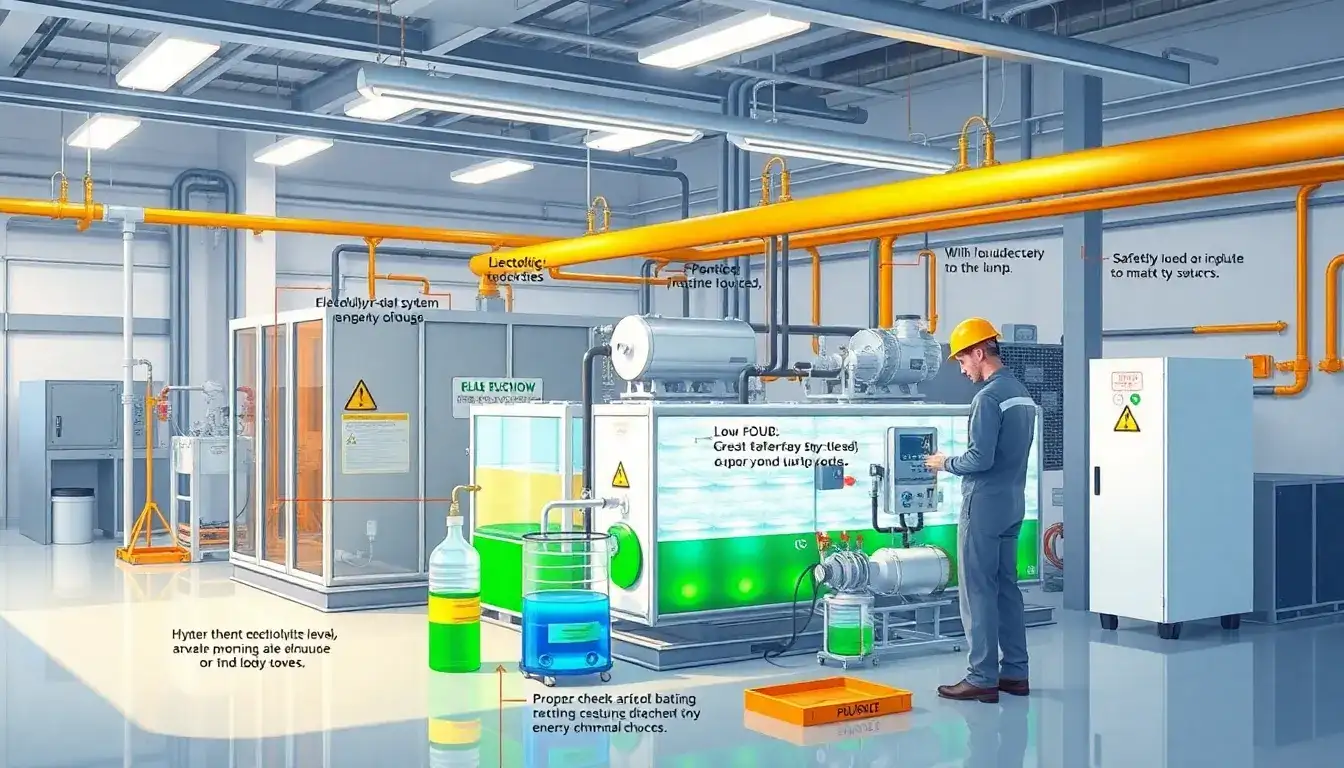

- Monitoring and Maintaining Electrolyte Levels:

- Check electrolyte levels regularly, typically every month.

- Replenish the electrolyte solution as needed to maintain optimal performance and prevent degradation.

- Balancing the Electrolyte State of Charge (SoC):

- Use the system’s control software to monitor and rebalance the SoC in the positive and negative tanks. An imbalance can reduce efficiency and performance.

- Inspecting and Cleaning the Cell Stack:

- Periodically inspect the cell stack for signs of fouling or wear.

- Clean the electrodes according to the manufacturer’s guidelines to prevent efficiency loss.

- Temperature Monitoring:

- Ensure the battery operates within a suitable temperature range, typically between 10°C and 40°C.

- Use temperature control systems if necessary to prevent component damage or electrolyte degradation.

- Regular System Diagnostics:

- Run built-in diagnostic tools to identify potential issues early.

- Monitor key performance metrics such as voltage efficiency, pump flow rates, and electrolyte conductivity.

- Annual Professional Inspections:

- Schedule annual inspections by certified technicians to address any underlying issues and ensure optimal performance.

- Environmental Control:

- Keep the battery environment clean and climate-controlled to avoid dust, humidity, and extreme temperatures that could compromise performance.

By following these maintenance tasks, flow batteries can maintain peak performance and extend their lifespan effectively.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-maintenance-tasks-for-flow-batteries/