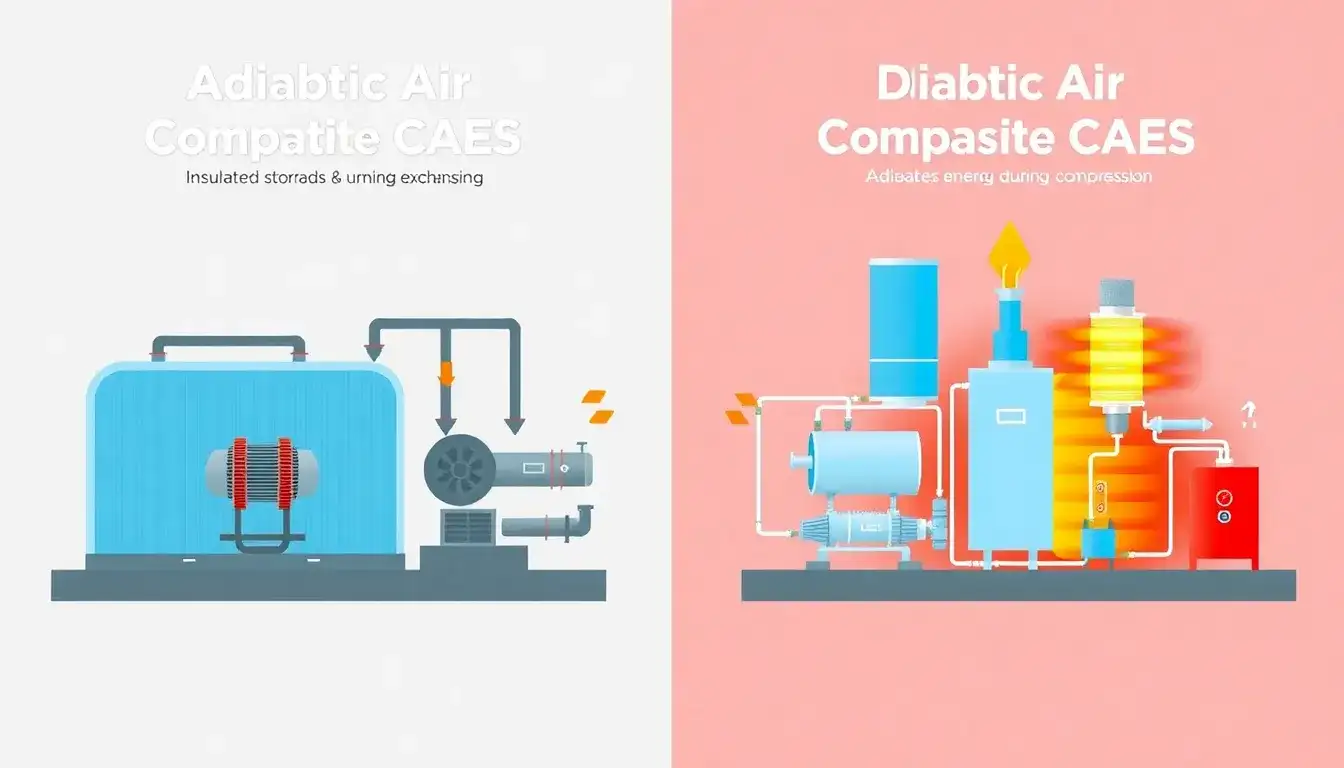

The main differences between adiabatic and diabatic Compressed Air Energy Storage (CAES) systems center on how they handle the heat generated during air compression and its use during expansion to generate electricity.

Adiabatic CAES (A-CAES)

- Heat Management: In adiabatic CAES, the heat produced during compression is captured and stored in a Thermal Energy Storage (TES) system instead of being discarded. This stored heat is then used to reheat the compressed air during the expansion phase, improving overall efficiency.

- System Efficiency: By recovering and reusing compression heat, adiabatic systems can theoretically approach 100% round-trip efficiency with perfect insulation. Practically, efficiencies exceed 70%, which is significantly higher than diabatic systems.

- Thermal Storage Mediums: Heat can be stored in solids like concrete or stone, fluids such as hot oil (up to 300 °C), or molten salts (up to 600 °C), or using packed bed thermal storage units.

- Operation: Ambient air is compressed to high pressure (up to ~70 bar or more), heated air is stored underground along with the thermal energy. During power generation, compressed air is expanded through turbines while the stored heat is reintroduced to maintain temperature, improving turbine efficiency.

- Development and Use: Adiabatic CAES is an area of active research, with no large-scale utility plants fully operational as of the latest data, but promising advancements exist especially with advanced adiabatic CAES (AA-CAES) involving multi-stage compression with inter-stage heat exchange.

Diabatic CAES (D-CAES)

- Heat Management: Diabatic CAES does not store the heat generated during compression. Instead, after each compression stage, the hot air is cooled to near-ambient temperature, and the heat is lost to the environment (waste heat).

- System Efficiency: Due to the loss of compression heat and the need for fuel-based reheating during expansion, diabatic CAES systems have lower round-trip efficiency, often around 40-50%.

- Operation: The compressed air is stored cold underground to reduce thermal stress on storage caverns. To generate power, the air is reheated by burning fossil fuels (typically natural gas) before expansion through turbines.

- Usage: Diabatic CAES is the more mature, older CAES technology. Existing CAES plants, such as the Huntorf plant, operate using this concept but have lower energy conversion efficiency and environmental downsides due to fossil fuel usage.

| Feature | Adiabatic CAES (A-CAES) | Diabatic CAES (D-CAES) |

|---|---|---|

| Heat generated during compression | Captured and stored for reuse | Discarded as waste heat |

| Heat storage medium | Thermal Energy Storage (solid, oil, molten salt) | None; heat lost to environment |

| Air temperature during storage | Stored at high temperature with heat recovery | Stored at near-ambient/cold temperature |

| Power generation | Air reheated using stored heat before expansion | Air reheated by burning fossil fuels before expansion |

| Round-trip efficiency | ~70% or higher | ~40-50% |

| Environmental impact | Lower; no fossil fuel combustion | Higher; fossil fuel combustion needed |

| Maturity of technology | Emerging, research stage | Mature, existing commercial plants |

In summary, adiabatic CAES systems improve upon diabatic ones by capturing and reusing the heat generated during compression, eliminating the need for fossil fuel combustion for reheating, thus offering higher efficiency and lower environmental impact. Diabatic CAES loses this heat and relies on additional fuel, resulting in lower efficiency and more emissions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-differences-between-adiabatic-and-diabatic-caes-systems/