Scaling up solid-state battery production poses several significant challenges, which can be broadly categorized into manufacturing complexity, material issues, and system integration challenges.

Manufacturing Complexity

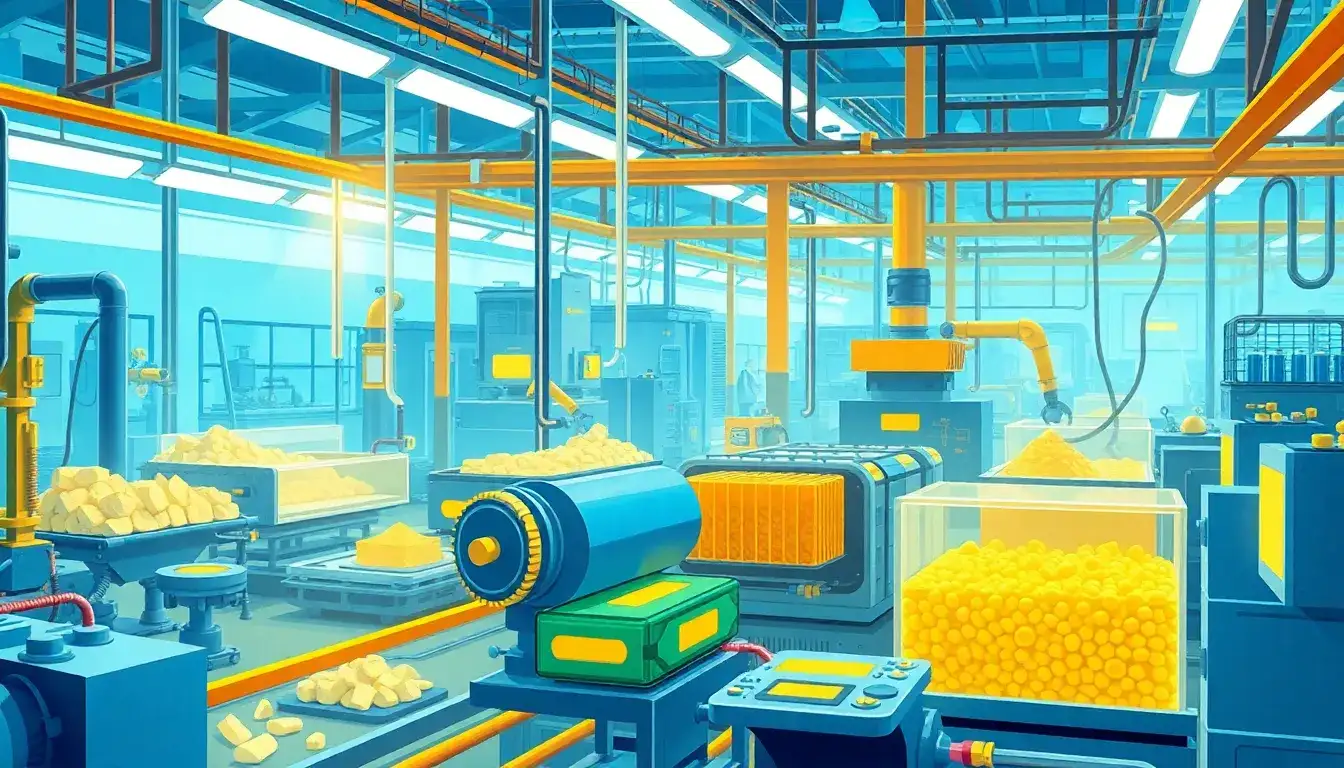

- Advanced Materials and Equipment: Producing solid-state batteries requires expensive and advanced materials, such as solid electrolytes (often ceramics or glass), which demand high precision and uniformity. Additionally, specialized equipment is necessary, increasing production costs.

- Scalability and Consistency: Transitioning from laboratory-scale production to mass manufacturing requires ensuring consistent quality and reliability across large production volumes. This necessitates significant investment in advanced manufacturing technologies and infrastructure.

- Handling Sensitive Materials: Many solid-state electrolytes are brittle or sensitive to moisture, requiring controlled environments like dry rooms during production.

Material Issues

- Mechanical Properties: Solid electrolytes must exhibit high ionic conductivity, chemical stability, and mechanical strength. Maintaining these properties at scale is challenging.

- Dendrite Formation: Preventing dendrite growth, which can cause short circuits, is a critical issue that demands innovative material compositions and manufacturing techniques.

- Material Britteness: The brittleness of some solid electrolytes limits packaging options and poses challenges in handling and manufacturing.

System Integration Challenges

- Interface Contact and Stress Management: Maintaining interfacial contact between solid components throughout the battery’s life cycle is essential. Managing stress applied to cell components adds complexity to manufacturing and system integration.

- Operating Temperature and Pressure: Higher operating temperatures and stack pressures required for optimal performance introduce new demands for thermal management systems, increasing vehicle complexity and cost.

- Safety and Thermal Management: The reactivity of lithium metal with moisture and air necessitates advanced flame retardation systems to prevent catastrophic thermal events, differing from those used in conventional lithium-ion batteries.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-challenges-in-scaling-up-solid-state-battery-production-3/