1. Manufacturing Process Immaturity and Scalability Concerns

- Lithium-sulfur battery manufacturing processes are not yet as mature or optimized as those for established lithium-ion batteries, leading to concerns about their scalability for mass production. The transition from pilot-scale to gigafactory-level production involves complexities that are not trivial to solve.

2. Quality Control and Production Speed

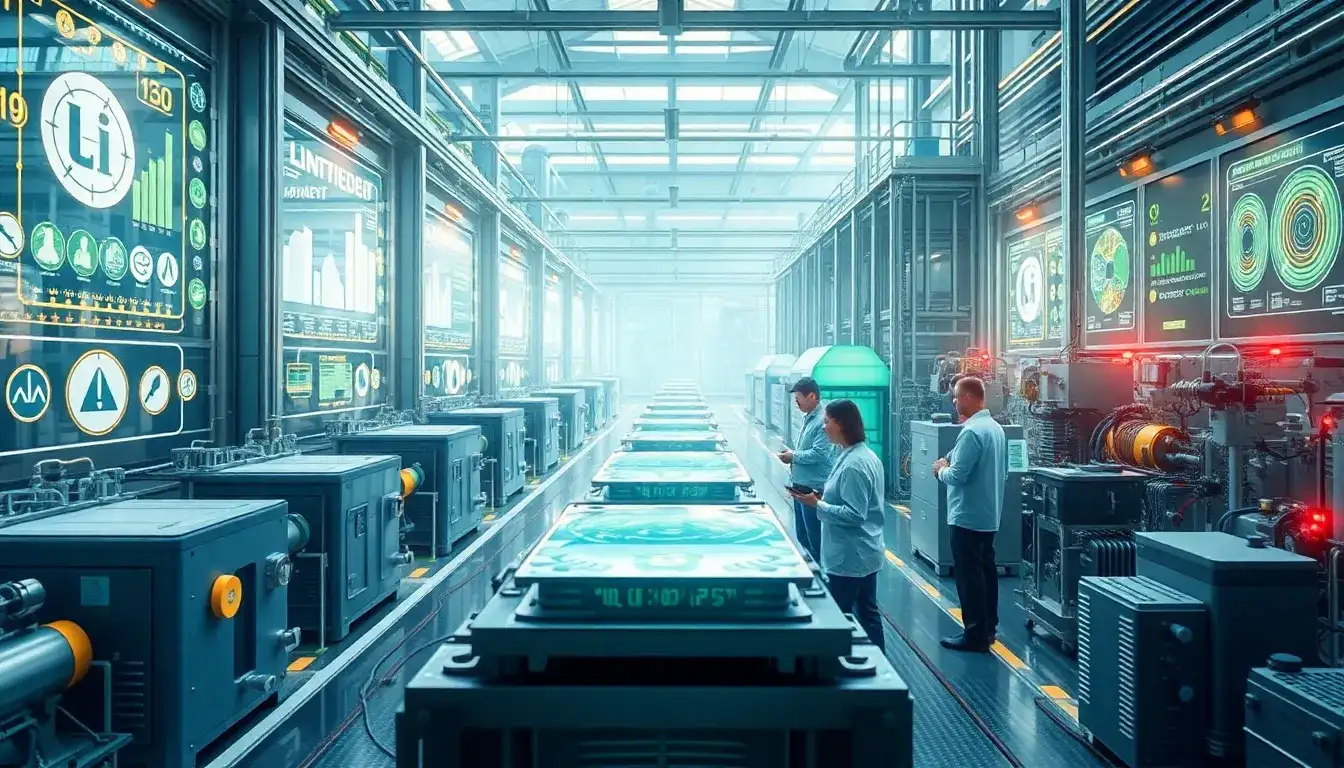

- Scaling up production means faster, automated assembly lines where detecting and fixing defects in real-time becomes more difficult. Small issues that are easily managed during slow pilot production can result in large batches of faulty cells on high-speed lines. Implementing advanced data management and digital monitoring tools is essential to maintain consistent quality during scale-up.

3. Low Cycle Life Due to Technical Limitations

- The key technological hurdle preventing Li-S batteries from mass adoption is their relatively low cycle life compared to lithium-ion alternatives. This is caused by several interrelated factors:

- Dendrite Formation on the Lithium Anode: Irregular growth of the solid electrolyte interface leads to dendrites that cause short circuits and premature battery failure.

- Polysulfide Shuttle Effect: Lithium polysulfides dissolve into the electrolyte, leading to loss of active material, corrosion of the anode, and reduced cycle life.

- Cathode Swelling: Sulfur cathodes experience significant volumetric expansion (up to 80%), which affects mechanical stability and performance over cycles.

4. Electrolyte Optimization Challenges

- Reducing electrolyte amounts to increase energy density (‘lean electrolyte’) tends to deteriorate the electrochemical reaction, impacting battery performance and lifespan. Finding a balance in electrolyte dosage that supports efficient reactions and durability remains a challenge.

5. Raw Material Sourcing and Supply Chain Stability

- Scaling any battery technology also involves securing raw materials reliably and sustainably. While this is not unique to Li-S batteries, the overall industry-wide pressure on battery supply chains poses a hurdle in meeting growing demand efficiently and cost-effectively.

Summary Table of Main Challenges in Scaling Lithium-Sulfur Battery Production

| Challenge | Description |

|---|---|

| Manufacturing immaturity | Lack of optimized, mature production processes for large scale |

| Quality control at high speed | Difficulties in detecting defects quickly on automated lines |

| Low cycle life | Technical issues like dendrite formation, shuttle effect, and cathode swelling |

| Electrolyte dosage balance | Lean electrolytes reduce performance; optimization is hard |

| Supply chain issues | Raw materials sourcing and supply stability |

Addressing these challenges requires continued R&D to improve battery chemistry and materials, investments in automated and data-driven manufacturing systems, and robust supply chain strategies to support scaling from pilot to mass production.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-challenges-in-scaling-up-lithium-sulfur-battery-production/