1. Complexity and Variability of Battery Designs and Chemistry

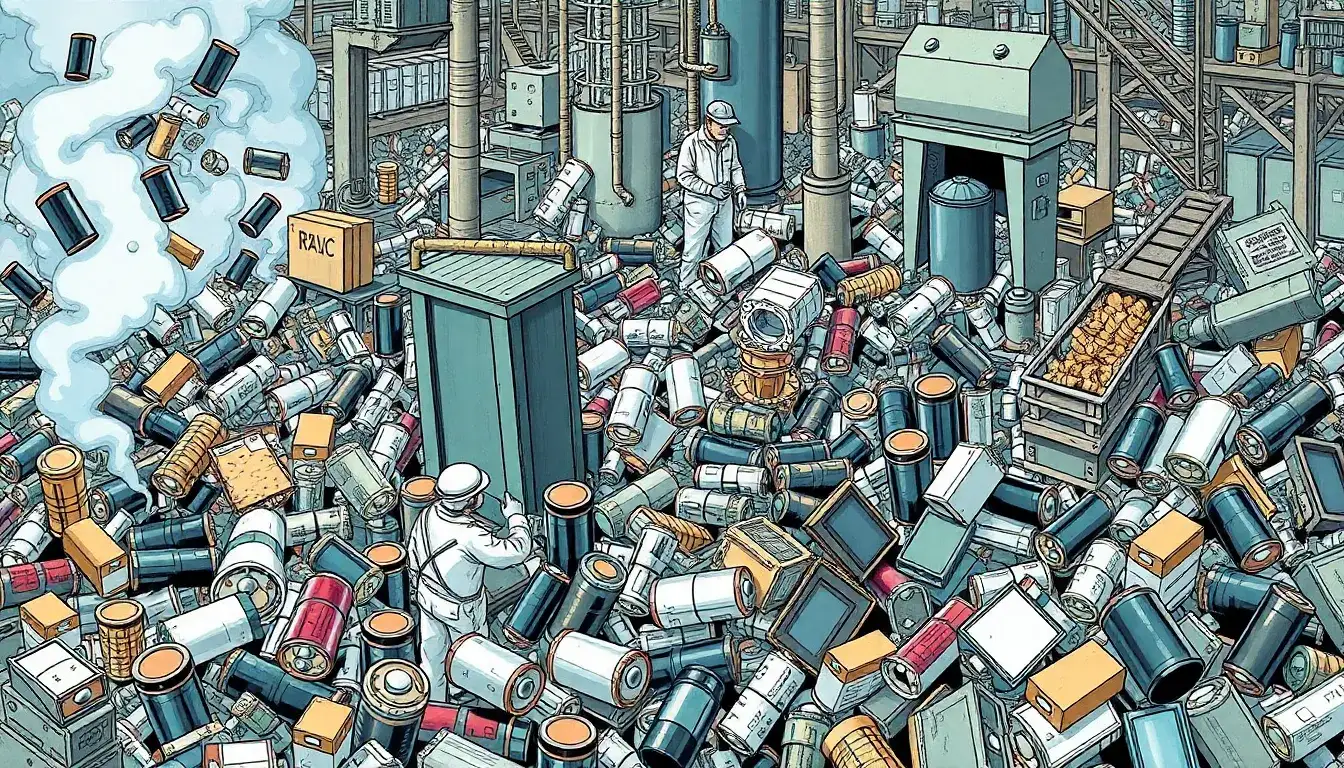

Lithium-ion batteries vary widely in their chemical compositions and structural designs. Different batteries use different combinations and proportions of materials such as lithium cobalt oxide, lithium nickel manganese cobalt oxide, and lithium nickel cobalt aluminum oxide. These variations require batteries to be carefully sorted and separated by their specific chemistry for effective recycling, which raises both costs and processing time. Moreover, the physical design of batteries is not standardized, making disassembly labor-intensive and often manual, especially for large battery packs that may include safety devices and sensors like those used in electric vehicles.

2. Safety Concerns in Handling, Storage, and Transportation

Lithium-ion batteries can pose fire and explosion risks, particularly if damaged or improperly handled. Storage and transportation require strict safety protocols to avoid incidents. Unlike other types of batteries (e.g., lead-acid), lithium-ion batteries demand careful handling due to their reactive and ignitable nature. This creates challenges in logistics for collecting and moving used batteries to recycling facilities safely.

3. Economic Viability and Market Fluctuations

Recycling lithium-ion batteries involves high costs related to sorting, disassembly, and chemical processing. Additionally, fluctuations in the prices of raw battery materials like lithium, cobalt, and nickel create economic uncertainty for recyclers. This can affect the incentive to invest in and scale up recycling operations, limiting the overall volume and efficiency of recycling.

4. Environmental Impact of Extraction and Recycling Processes

While recycling aims to reduce environmental harm, the process itself can pose challenges. Extracting lithium and other metals from batteries sometimes involves water-intensive processes and risks of toxic overflow into soil and water. Recycling operations need to manage these environmental risks carefully to truly be sustainable.

In summary, the key challenges are:

- Diverse and complex chemical compositions and designs, requiring manual, costly sorting and disassembly.

- Safety risks associated with battery handling, storage, and transport.

- Economic uncertainty due to fluctuating raw material prices and high processing costs.

- Environmental concerns related to resource extraction and recycling processes.

Addressing these challenges requires technological innovations in battery design, improved recycling technologies that can handle diverse chemistries more efficiently, safer logistic protocols, and stable market conditions to support scaled recycling efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-challenges-in-recycling-lithium-ion-batteries-3/