The main challenges in producing solid-state batteries (SSBs) center around material issues, manufacturing complexity, and performance limitations:

Material and Interface Challenges

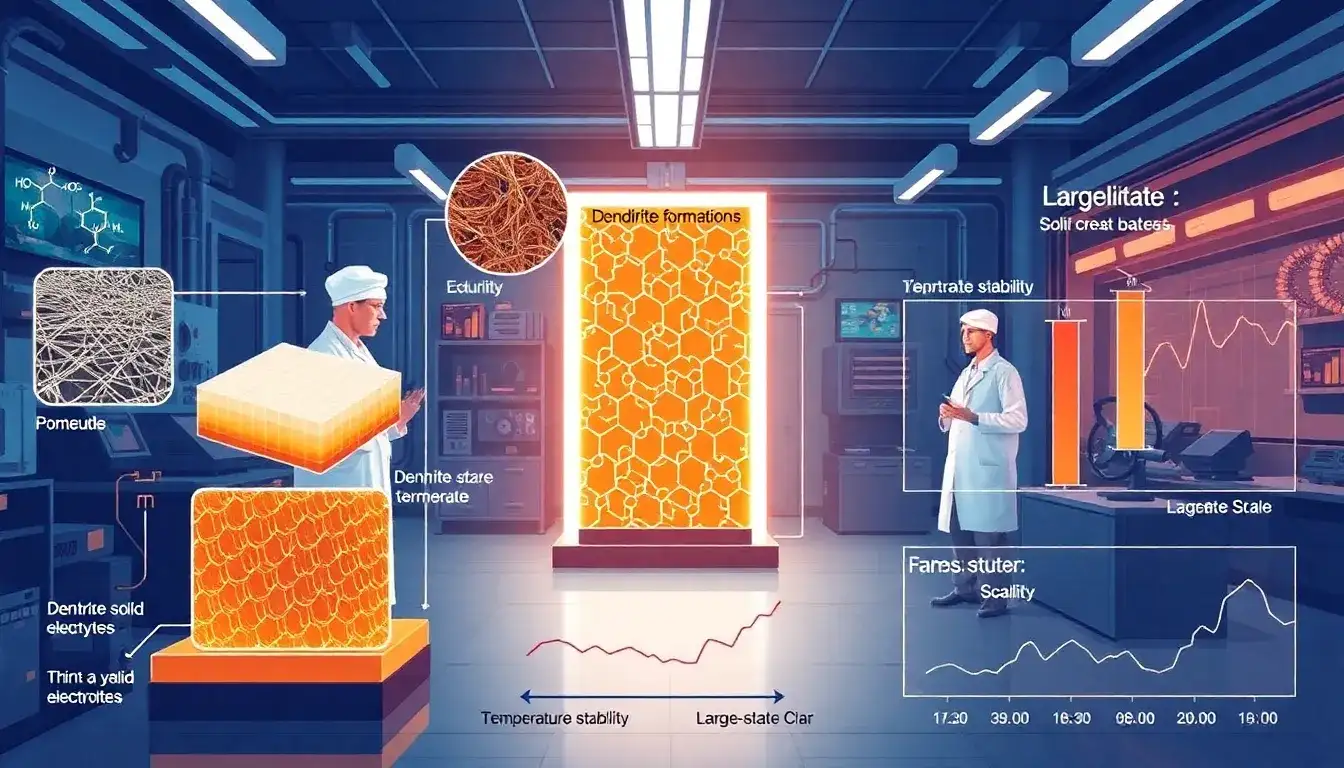

- Dendrite Formation: Even solid electrolytes can still experience dendrite growth (needle-like structures) during charging, which can cause short circuits and battery failure.

- Solid Electrolyte Behavior: Engineering teams often lack comprehensive real-world data on solid electrolytes under temperature fluctuations and mechanical stress, complicating performance optimization.

- Interfacial Stability: Achieving good, stable contact between the solid electrolyte and electrodes remains difficult, causing high interfacial resistance and performance degradation during charge-discharge cycles.

- Brittleness: Many solid electrolytes (e.g., ceramics) are brittle, making handling in manufacturing complex and causing potential cracks or mechanical failure during EV operation.

- Material Selection: Selecting appropriate materials, such as lithium metal anodes or silicon, is challenging due to their reactive nature, volume changes, and degradation risks, which affect battery safety and longevity.

Manufacturing and Scalability Challenges

- Complex Fabrication: Producing thin, defect-free solid electrolyte layers with precise electrode contact is a complex process requiring advanced facilities and dry rooms to prevent moisture contamination.

- Scaling Production: Transitioning from laboratory to large-scale gigawatt-hour manufacturing requires heavy investment, advanced manufacturing technology, skilled labor, and rigorous quality control to maintain consistency and reliability across large volumes.

- Cost and Infrastructure: The cost of specialized materials, equipment, and the establishment of large-scale production infrastructure poses economic challenges for commercialization.

Performance Limitations

- Slow Charging and Discharging: Current solid-state batteries face bottlenecks in charging and discharging speeds compared to liquid electrolyte batteries, limiting practical application especially for fast-charging EVs.

- Capacity Decay: Rapid capacity loss during cycling impacts the battery lifespan and reliability, with challenges related to mechanical and chemical stability over time.

- Balancing Membrane Thickness and Strength: Solid polymer electrolytes (SPEs) require trade-offs between membrane thickness for mechanical strength and ionic conductivity, which affects overall performance.

In summary, the primary hurdles are ensuring stable, durable solid electrolyte interfaces, overcoming brittleness and dendrite risks, developing scalable and cost-effective manufacturing processes, and improving the batteries’ charging speeds and lifespan. These challenges collectively slow the path toward commercial viability despite the promising advantages of solid-state battery technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-challenges-in-producing-solid-state-batteries/