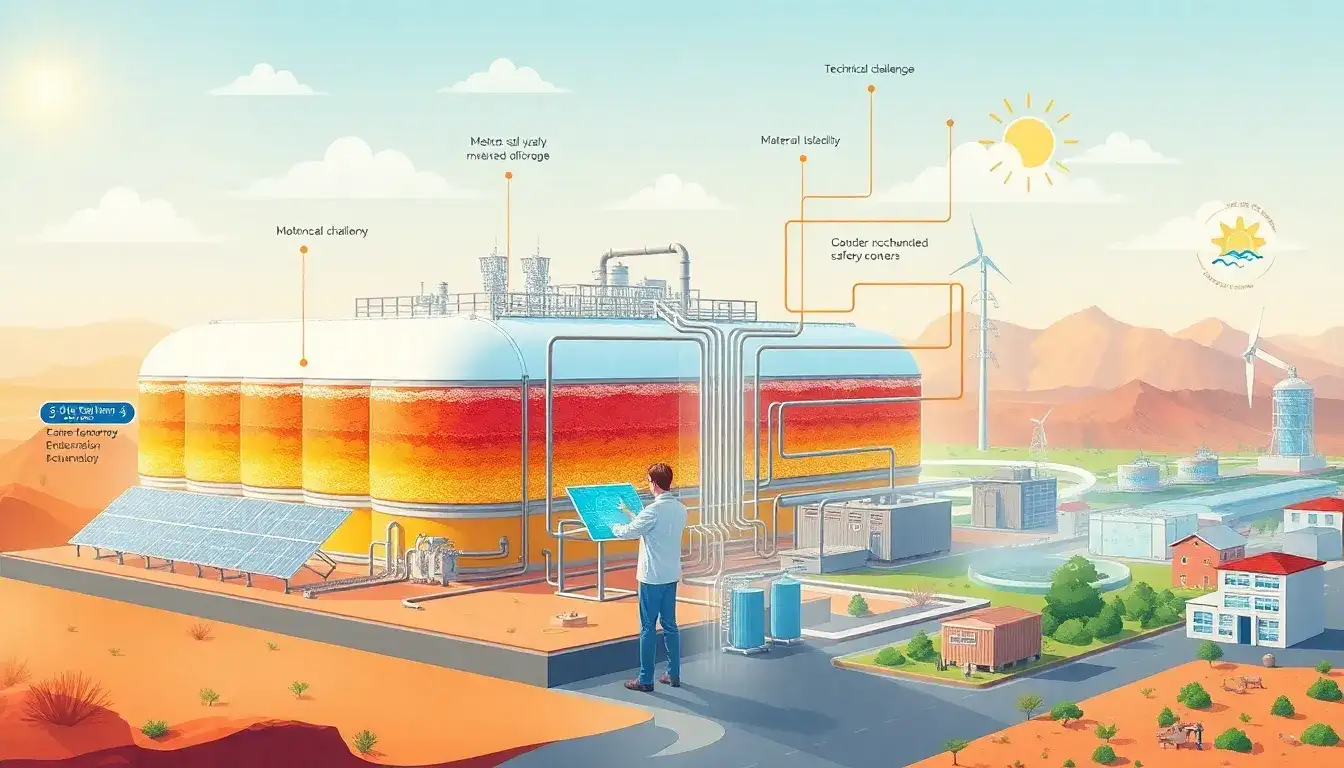

The implementation of molten salt energy storage systems faces several key challenges:

1. Material Stability and Corrosion at High Temperatures

Traditional molten salts like Solar Salt and Hitec Salt struggle with thermal degradation and accelerated corrosion of storage tanks and piping at operational temperatures up to 565°C. Failures in central receiver CSP plants have been linked to tank design flaws and material limitations, particularly under prolonged high-temperature stress.

2. High Costs and Infrastructure Requirements

Initial investments are substantial due to specialized materials (e.g., Hastelloy alloys), corrosion-resistant components, and large-scale infrastructure for tanks and heat exchangers. Maintenance and operational expenses further strain budgets, especially in developing economies.

3. Temperature Management Challenges

Molten salt systems must remain above 250°C to avoid solidification, necessitating continuous energy input for heating and increasing operational costs. This requirement complicates deployment in colder climates without auxiliary heating systems.

4. Design and Fabrication Complexity

Large-scale tank fabrication faces technical hurdles, particularly post-weld heat treatment for stress relief in massive structures (diameters >30 m). Failures in early CSP plants highlight the need for optimized welding protocols and material standards.

5. Limited Low-Temperature Adaptability

Existing nitrate-based salts freeze at temperatures above 0°C, restricting use in colder regions. While research explores additives like lithium and magnesium to lower freezing points, these formulations remain experimental.

6. Operational Risks

Aggressive thermal cycling and non-uniform heat distribution in storage tanks can accelerate material fatigue, leading to leaks or structural failures over time.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-challenges-in-implementing-molten-salt-energy-storage-systems/