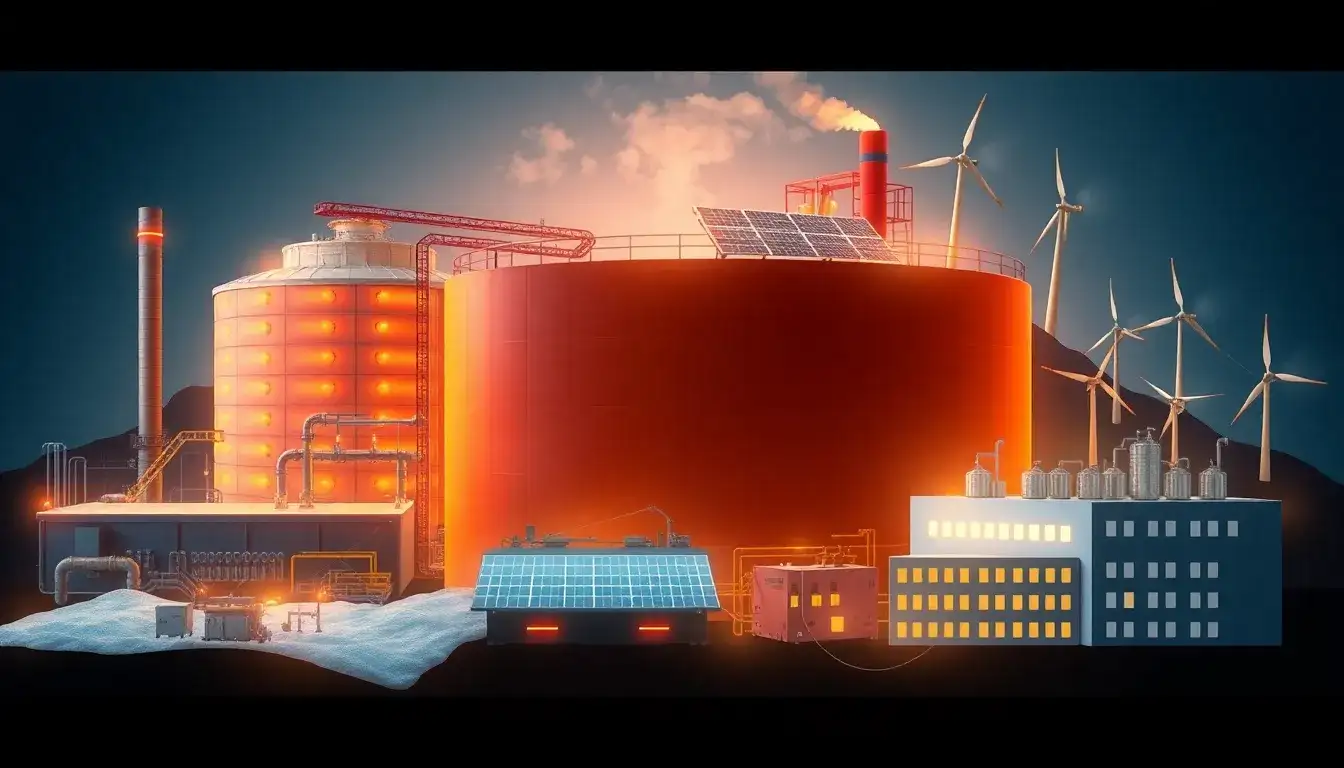

Thermal energy storage (TES) has several main applications in industries, primarily focusing on decarbonizing processes, improving energy efficiency, and enabling the use of renewable energy sources for industrial heat needs. The key industrial applications include:

Main Applications of Thermal Energy Storage in Industries

<strong>1. High-Temperature Process Heat for Heavy Industries</strong><br>

TES is vital for industries like steel, cement, and iron manufacturing, which require very high temperatures (often above 1,000°C) for their processes. These sectors are among the hardest to decarbonize due to their heavy reliance on fossil fuels. TES systems can store thermal energy at these high temperatures, allowing industries to replace fossil fuel heat with renewable electricity converted into stored heat, significantly reducing CO2 emissions.

<strong>2. Industrial Process Heating</strong><br>

TES is used to supply process heat in various forms including calcination, drying, and heating of process fluids. This application spans a wide range of industries such as chemical production, paper and pulp, and methanol synthesis, which often require lower-temperature heat but benefit from the flexibility TES provides in managing energy loads and integrating intermittent renewable energy sources.

<strong>3. Decarbonizing Heat Supply and Enhancing Energy Flexibility</strong><br>

By storing heat generated from surplus or low-cost renewable electricity (e.g., solar or wind), TES enables industries to use renewable energy more reliably and on demand. This approach helps in balancing intermittent electricity supply and providing clean, dispatchable heat, thereby reducing dependence on fossil fuels like natural gas. Examples include systems that heat refractory bricks to temperatures up to 1,500°C for later heat release, which can be used directly for process heat or to generate steam.

<strong>4. Combined Heat and Power (CHP) Systems</strong><br>

TES can be integrated with CHP setups where thermal storage units supply both heat and power. This dual functionality increases energy efficiency in industrial plants by producing baseload electricity alongside clean thermal energy for industrial processes, further reducing greenhouse gas emissions.

<strong>5. Waste Heat Recovery and Use in HVAC Systems</strong><br>

TES facilitates capturing and storing waste heat from industrial processes, enabling its reuse in heating, ventilating, and air conditioning (HVAC) systems or other process heating needs. This application improves overall energy efficiency and lowers operational costs and emissions in industry.

Summary Table of Industrial TES Applications

| Application | Industry Examples | Temperature Range | Benefits |

|---|---|---|---|

| High-temperature process heat | Steel, cement, iron | >1,000°C | Decarbonization of hard-to-abate sectors |

| Process heat for chemical, paper | Methanol, paper & pulp, chemicals | Low to mid temperature | Energy flexibility, renewable integration |

| Heat storage from renewable electricity | Various industries | Up to 1,500°C | Renewable heat dispatchability |

| Combined Heat and Power (CHP) | Industrial plants with CHP systems | Variable | Efficient heat and power supply |

| Waste heat recovery & HVAC support | Multiple industrial sectors | Variable | Improved energy efficiency, cost savings |

In conclusion, thermal energy storage is increasingly critical in industrial applications to help reduce fossil fuel use, integrate renewable energy, and cut greenhouse gas emissions, particularly in energy-intensive and high-temperature sectors like steel, cement, and chemical processing.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-applications-of-thermal-energy-storage-in-industries/