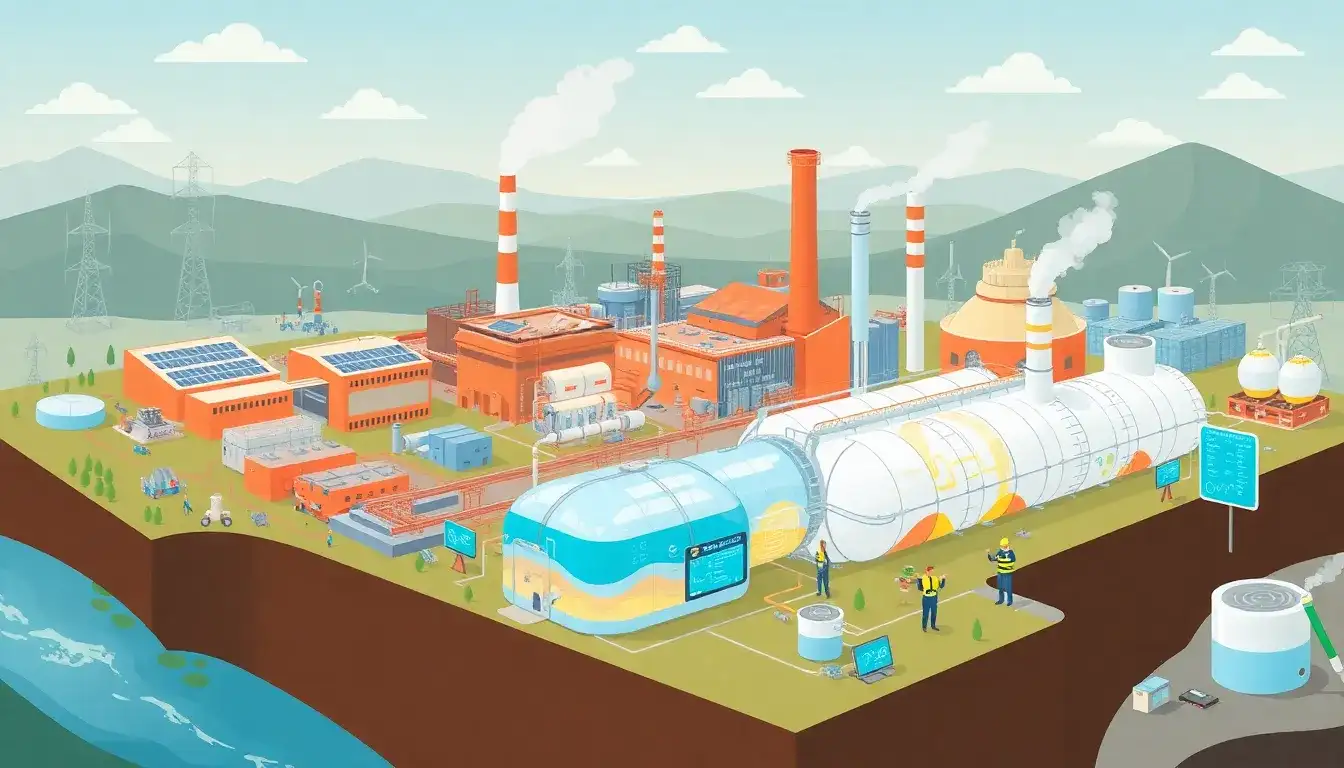

Main Applications of TES in Industrial Processes

- High-Temperature Process Heat:

- Cement, Steel, and Iron Production: TES systems can provide the high temperatures (over 1,000°C) needed for these processes, helping to decarbonize hard-to-abate sectors.

- Methanol and Paper Production: Lower temperature heat from TES can be utilized in these applications as well as for district heating.

- Combined Heat and Power (CHP):

- Systems like Rondo Energy’s Heat Battery allow thermal energy to be converted into both heat and power using steam turbines, offering baseload electricity generation alongside process heat.

- Seasonal Storage:

- TES can store heat from summer for winter use, significantly reducing reliance on fossil fuels for heating purposes.

- Energy Efficiency and Waste Heat Recovery:

- By storing waste heat or excess energy from industrial processes, TES systems can improve overall energy efficiency and reduce energy consumption.

- Grid Stability and Demand Response:

- TES can help manage renewables’ intermittency by storing energy during periods of low demand and releasing it when needed. This capability also supports grid stability and enables participation in demand response programs.

These applications highlight TES’s potential to transform industrial heating by leveraging renewable energy sources, thus contributing to a more sustainable and decarbonized industrial sector.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-main-applications-of-thermal-energy-storage-in-industrial-processes/