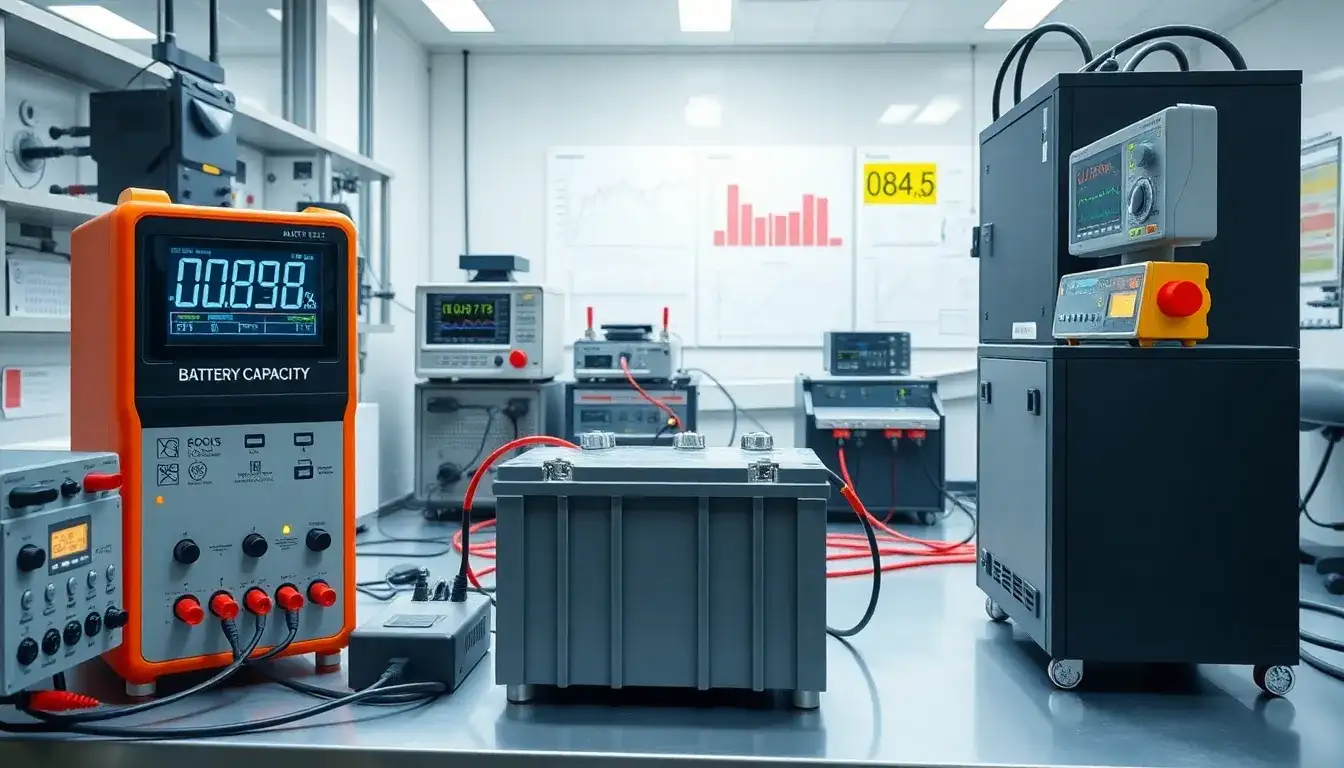

During a battery capacity test, several key components need to be verified to ensure accurate and reliable results. Here are the main aspects to focus on:

Key Components to Verify

-

Voltage and Current Measurements:

- Monitor the overall battery voltage and individual cell voltages throughout the test.

- Measure the discharge current and ensure it remains at a specified C-rate during the test.

-

Time and Capacity Calculation:

- Record the time it takes for the battery to discharge from its fully charged state to a specified cutoff voltage.

- Calculate the actual capacity in ampere-hours (Ah) or watt-hours (Wh) by multiplying the current by time.

-

Temperature Adjustments:

- Ensure that temperature conditions are maintained and corrected for during the test, as temperature affects battery capacity. A cold battery may show less capacity than a warm one.

-

Cutoff Voltage:

- Establish a specific end-of-discharge voltage to safely terminate the test and protect the battery from deep discharge.

-

Individual Cell Performance:

- Monitor and record individual cell voltages at intervals and especially at the end of the test to identify weak cells.

-

Verification of Rated Capacity:

- Compare the measured capacity to the manufacturer’s rated capacity to ensure the battery meets specifications.

-

Physical and Electrical Integrity:

- Conduct a visual inspection for any physical damage or defects and ensure all electrical connections are secure and within specifications.

These components are crucial for ensuring a comprehensive and accurate battery capacity test.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-key-components-to-verify-during-a-battery-capacity-test/