Energy storage cylinder manufacturers are companies that specialize in the production and design of cylindrical devices capable of storing various forms of energy. 1. These manufacturers contribute significantly to green technology, 2. Enhance energy efficiency, 3. Cater to diverse industries, 4. Innovate with advanced materials and technologies. One prominent aspect includes the utilization of emerging technologies to improve storage capacity and efficiency. For instance, utilizing advanced materials such as graphene and other composites can substantially increase the energy storage capacity per unit volume. Additionally, manufacturers are keen on developing systems that can manage fluctuating energy demands, particularly relevant in the renewable energy sector where energy availability can be inconsistent. This innovation facilitates a more resilient energy grid, allowing for effective integration of renewable energy sources such as solar and wind power.

ENERGY POLICY AND GOVERNMENT REGULATIONS

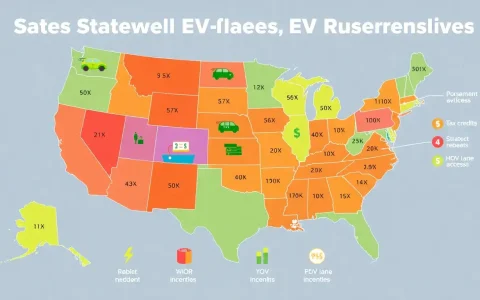

Navigating the landscape of energy storage cylinder manufacturing mandates a keen understanding of energy policies and governmental regulations. As global concerns over climate change amplify, many governments are instituting favorable policies that encourage the development of renewable energy storage solutions. Compliance with these regulations is not merely a matter of adhering to laws; it shapes the entire production process. Understanding compliance mandates is essential for manufacturers as they streamline operations and minimize legal repercussions. In this environment, manufacturers benefit from government incentives, tax credits, and grants formulated to foster innovation and sustainability.

Moreover, regulatory frameworks dictate the safety and environmental standards applicable to energy storage devices. This encompasses everything from material sourcing and production methods to disposal strategies at the end of a product’s life cycle. Manufacturers must remain agile, adapting to often fluid governmental guidelines that are influenced by new scientific findings and public sentiment. By proactively engaging with regulatory bodies, manufacturers can shape the policies that govern their operations, ensuring that both they and the environment benefit from sustainable practices.

MATERIALS USED IN ENERGY STORAGE CYLINDERS

The selection of materials for energy storage cylinders is critical, influencing the efficiency, cost, and longevity of the devices. Traditional materials such as lead-acid and nickel-cadmium have their advantages, primarily in cost-effectiveness; however, they are less favored due to environmental concerns and limited lifespan. Innovative materials such as lithium-ion, solid-state structures, and organic compounds are becoming increasingly prevalent. These materials offer distinct advantages, including greater energy densities, longer lifespans, and reduced environmental impact.

Lithium-ion batteries, for instance, serve as a cornerstone in modern energy storage solutions, especially concerning electric vehicles and renewable energy systems. Despite their robust performance, challenges such as resource scarcity and recycling difficulties remain pertinent. Solid-state batteries are being explored as an alternative, providing increased safety and energy density but are still hindered by high production costs. Emerging organic materials represent a novel approach, aiming to leverage sustainable resources and create biodegradable solutions that minimize ecological footprints.

Adoption of these newer materials demands extensive research and development, fostering competition among manufacturers. Continuous efforts to innovate not only aim for better performance metrics but also seek to address pressing environmental concerns associated with existing materials.

APPLICATIONS ACROSS INDUSTRIES

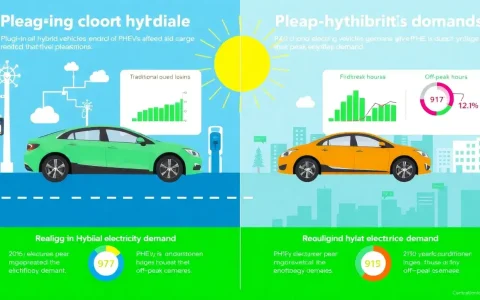

The versatility of energy storage cylinders enables their application across a myriad of industries. From transportation to telecommunications, their pivotal role in enhancing operational efficiency cannot be overstated. In the transportation sector, especially electric vehicles (EVs), energy storage cylinders store electrical energy, facilitating the transition from fossil fuels to clean energy alternatives. The growing market for EVs has propelled manufacturers to innovate, leading to advancements in battery technology and charging infrastructure.

In telecommunications, uninterrupted power supplies (UPS) are essential for maintaining network reliability, making energy storage cylinders integral to operations. These batteries ensure that critical communication systems remain functional during outages. Robust energy storage systems enable telecom companies to manage peak loads effectively, improving service availability. Moreover, industries such as healthcare and finance rely heavily on consistent power supplies, emphasizing the critical nature of energy storage cylinders in daily operations. By analyzing usage patterns and predicting demand surges, companies can implement energy storage solutions to boost resilience against potential disruptions.

ENVIRONMENTAL IMPACT AND SUSTAINABILITY

Amid rising environmental awareness, manufacturers are determining the ecological implications of energy storage cylinders. The lifecycle of these devices—from raw material extraction to disposal—demands a comprehensive assessment of their environmental footprint. A fundamental challenge is the end-of-life management of various materials used in batteries, such as lithium and cobalt, which can pose significant environmental hazards when improperly discarded.

Encouragingly, advancements in recycling technologies are being realized. New processes enable the efficient recovery of valuable materials from spent batteries, significantly decreasing the need for virgin resources and ensuring a circular economy. Efforts to enhance sustainability also focus on reducing energy consumption during production and discovering alternative, less harmful materials.

Furthermore, the energy storage industry’s transition toward eco-friendly practices aligns with broader environmental goals such as reducing greenhouse gas emissions. By committing to sustainable sourcing, responsible production, and effective recycling, manufacturers contribute to a more sustainable future. The industry thus finds itself at a crossroads, where economic growth harmonizes with environmental stewardship.

FUTURE TRENDS IN ENERGY STORAGE TECHNOLOGIES

The landscape of energy storage solutions continues to evolve rapidly, with numerous trends shaping the future of cylinder manufacturing. One major trend is the increased integration of artificial intelligence (AI) and machine learning in optimizing energy management systems. Analysts predict that AI can improve energy efficiency, predict usage patterns, and allow better allocation of resources, making storage systems more intelligent and efficient.

Furthermore, as the world shifts toward renewable energy sources, manufacturers are increasingly investing resources into the development of large-scale energy storage systems. These systems are imperative for tackling intermittency issues associated with wind and solar energy. New technologies such as flow batteries and ultra-capacitors are gaining traction, promising longer cycles and enhanced lifecycle performance.

Moreover, as consumer demand for cleaner energy solutions rises, so does the need for collaborative platforms that integrate various storage technologies. The emergence of hybrid systems, combining different forms of energy storage, presents a promising avenue for enhancing overall system performance. The energy storage sector is poised for transformation, with innovative advancements leading the charge toward greater efficiency, affordability, and sustainability.

BUSINESS MODELS AND ECONOMIC CONSIDERATIONS

Energy storage cylinder manufacturers are not only contending with technological challenges but also navigating complex business models. The economics surrounding energy storage have shifted as market dynamics evolve, leading to innovative pricing mechanisms and partnerships. Traditional sales models are giving way to new strategies such as leasing, subscription services, and performance-based contracts, which lower upfront costs and create ongoing revenue streams for manufacturers.

Additionally, the capital-intensive nature of energy storage projects invites investment from multiple stakeholders, including private investors, public institutions, and energy providers. Collaboration and partnerships become crucial, allowing manufacturers to pool resources and share risks while benefiting from shared expertise. This collaborative environment fosters innovation, helping companies stay agile and responsive to market demands.

The significance of cost reduction is undeniable as manufacturers strive to make energy storage more accessible to businesses and consumers. Continuous improvements in manufacturing processes and economies of scale can reduce the final cost of energy storage solutions. Increased competition within the industry further drives prices down, benefiting end-users while promoting widespread adoption of storage technologies.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE TECHNOLOGIES ARE AVAILABLE?

Numerous energy storage technologies cater to different applications and needs. The most common types include batteries, pumped hydro, compressed air, and thermal storage. Each offers specific advantages. Batteries, such as lithium-ion, are popular for their high energy density and responsiveness, making them ideal for electric vehicles and grid storage. Pumped hydro storage utilizes gravitational potential energy by moving water between elevations, providing large-scale storage solutions. Compressed air energy storage involves using surplus energy to compress air, which is released to generate electricity during peak demand. Thermal energy storage systems capture heat for later use in heating or power generation, optimizing energy consumption patterns.

HOW DOES ENERGY STORAGE IMPACT RENEWABLE ENERGY INTEGRATION?

Energy storage systems are vital for fulfilling the promise of renewable energy sources, which can be intermittent in availability. By storing excess energy produced during peak generation times, storage systems can supply power during periods of low generation. This capability allows for a more balanced energy grid and reduces reliance on fossil fuels during peak demand. Integrated storage solutions not only increase the viability of solar and wind energy but also enhance grid reliability and reduce electricity prices for consumers.

WHAT ARE THE ENVIRONMENTAL CONCERNS ASSOCIATED WITH ENERGY STORAGE?

While energy storage technologies, particularly batteries, offer many advantages, they also present environmental concerns. The extraction of raw materials, such as lithium and cobalt, can lead to significant ecological damage and ethical issues related to labor practices. Moreover, the end-of-life handling of batteries poses challenges, as they may contain hazardous materials. Proper recycling and disposal measures are crucial to mitigate these risks. The industry is making strides toward more sustainable practices, including improving recycling technologies, leveraging eco-friendly materials, and promoting circular economies that reduce environmental impact.

The discourse surrounding energy storage cylinder manufacturers encapsulates a dynamic and evolving arena, shaped by technological advancements and environmental considerations. Emphasizing the role these manufacturers play in enhancing energy storage capabilities reveals their fundamental importance in a transitioning energy landscape. Their contributions enhance energy efficiency, drive sustainability, and facilitate the adoption of renewable energy sources, ultimately reshaping how power is managed and consumed. With materials innovation and integrative technologies offering pathways forward, the energy storage industry stands at the cusp of a revolution. As government policies bolster investments in clean energy, the ability of these manufacturers to respond and adapt will significantly influence future energy paradigms. Leading manufacturers are not merely fabricators; they are pivotal players shaping the future trajectory of global energy consumption. The time has come for energy storage cylinder manufacturers to rise to the occasion, spearheading efforts that combine innovation, responsibility, and economic viability. With cooperation among industries and the public sector, the potential for widespread adoption of advanced energy storage solutions can flourish, enabling the transition toward a more sustainable and resilient energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-energy-storage-cylinder-manufacturers/