Retrofitting industrial facilities with energy storage systems presents several challenges. 1. Financial implications, including high initial investment costs, complicate the process. Companies often face substantial upfront expenses that deter implementation. 2. Integration complexity arises from fitting new technology into existing infrastructures, requiring expert knowledge and careful planning. Each industrial setup has unique requirements that demand tailored solutions. 3. Regulatory hurdles, such as compliance with local laws and standards, can slow down or halt projects. Navigating the legal landscape often consumes time and resources. 4. Energy management strategies must be developed to ensure optimal usage and performance of the energy storage systems. Without an effective plan, the benefits of the systems may not be fully realized.

1. FINANCIAL IMPLICATIONS

Retrofitting industrial facilities with energy storage systems inevitably involves significant financial considerations. Companies must account for the initial outlay, which encompasses the cost of the technology, installation, and necessary upgrades to existing infrastructure. This investment can often seem daunting, particularly for smaller enterprises or those operating on tight budgets. Financial models must be meticulously crafted to project long-term savings against the immediate costs, emphasizing the importance of energy storage systems in reducing operational expenses in the future.

Furthermore, the availability of financing options plays a crucial role in determining the feasibility of these projects. Depending on the region and the specific industry, there may be state or federal incentives aimed at promoting energy efficiency and sustainability practices. Companies should explore grants, tax incentives, and low-interest loans designed to ease the financial burden. Proper financial planning, therefore, equates not only to an assessment of the costs involved but also to a comprehensive understanding of the economic benefits presented by energy storage solutions over time.

2. INTEGRATION COMPLEXITY

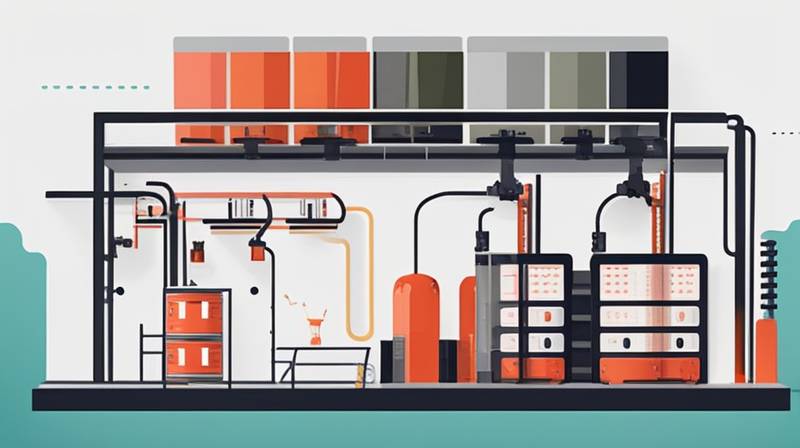

The challenge of integrating energy storage systems within existing industrial frameworks cannot be understated. Every facility operates on a unique set of processes and equipment, requiring customized solutions that may not always be readily available. This complexity necessitates a thorough analysis of both current operations and the desired outcomes of incorporating such technology. Engineers and energy consultants are often called upon to conduct feasibility studies and compatibility assessments to determine the best course of action.

Moreover, the technical difficulties of connecting new storage systems to older, often outdated infrastructure must be addressed. This may include retrofitting older control systems or upgrading electrical grids to handle the increased load from energy storage units. The integration process is time-consuming and demands collaboration between various stakeholders, including engineers, facility managers, and financial planners. The challenges are not just technical; they also involve a significant shift in how energy is managed within the facility, bringing about a need for training and education for the personnel responsible for operating the systems.

3. REGULATORY HURDLES

Navigating the regulatory landscape surrounding the installation of energy storage systems in industrial settings can be cumbersome. Compliance with local, state, and federal regulations is paramount, especially in industries where stringent safety and environmental standards are enforced. Facilities must ensure that their energy storage solutions comply with existing laws pertaining to hazardous materials, emissions, and energy grid connectivity.

In some cases, obtaining the necessary permits or approvals from relevant authorities can delay or obstruct project implementation. This bureaucratic red tape often necessitates the hiring of legal or regulatory experts who specialize in energy laws, further inflating project costs. Understanding the myriad regulations and potential impacts is essential for successful project execution. Companies need to proactively engage with regulators early in the planning process to identify potential roadblocks and address them efficiently.

4. ENERGY MANAGEMENT STRATEGIES

For energy storage systems to deliver optimal results, effective energy management strategies are indispensable. Facilities must develop a comprehensive plan that outlines how energy will be stored, utilized, and monitored. Simply installing a storage system without a strategy risks underutilization or inefficient operation, negating many of the anticipated benefits.

Furthermore, these strategies must adapt to the unique energy consumption patterns of each facility. An in-depth analysis of energy usage data provides insights into peak consumption times and helps determine the ideal size and type of energy storage system required. Continuous monitoring and adjustment of strategies will ensure that the system operates efficiently amidst changing operational dynamics. Companies must leverage advanced data analytics and smart technology to optimize their energy management strategies and maximize returns on their energy storage investments.

FAQs

WHAT ARE THE ECONOMIC BENEFITS OF ENERGY STORAGE IN INDUSTRIAL FACILITIES?

Implementing energy storage systems in industrial environments leads to various economic advantages. Cost savings through reduced energy bills represent a primary benefit, as facilities can store energy during off-peak hours when rates are lower and utilize it during peak times. This shifting of energy usage effectively minimizes reliance on expensive grid electricity, leading to significant reductions in overall energy costs.

Moreover, energy storage provides a buffer against rising energy prices, allowing companies to predict their expenses more accurately. In addition, many regions offer financial incentives such as rebates, tax credits, or grants for implementing energy-efficient technologies. By investing in energy storage, companies may qualify for these incentives, further enhancing their financial position. These factors combined indicate that the economic viability of energy storage systems extends well beyond the initial investment.

HOW LONG DOES IT TAKE TO RETROFIT AN INDUSTRIAL FACILITY?

The duration of retrofitting an industrial facility with energy storage systems can vary widely based on multiple factors. Typically, the process can take several months to a few years from initial planning through to full implementation. Key factors influencing this timeline include the complexity of the existing systems, the need for custom integration solutions, and the scope of regulatory approvals required.

Additionally, engaging with professional consultants and contractors can expedite the process; however, thorough planning and assessments are essential. These preliminary stages may involve feasibility studies and cost-benefit analyses, which can elongate the timeline. Ultimately, careful project management and proactive engagement with stakeholders at every level will facilitate a smoother and more efficient retrofitting process.

WHAT ARE THE COMMON TYPES OF ENERGY STORAGE SYSTEMS USED IN INDUSTRY?

Several types of energy storage systems are commonly deployed across industrial applications, each offering distinct advantages. Battery energy storage systems, particularly lithium-ion batteries, have gained popularity due to their efficiency and scalability. They allow for fast response times, making them suitable for balancing grid fluctuations and storing surplus renewable energy.

Another prevalent option is pumped hydro storage, which is suited for facilities located near water sources. This system utilizes excess energy to pump water to a higher elevation, subsequently generating electricity as it is released back down. Additionally, thermal energy storage systems, which store heat rather than electricity, are increasingly being used in industrial processes that require warmth or hot water. Each of these systems can be tailored to meet specific energy needs, thus enhancing the operational efficiency of industrial facilities.

**The transition towards integrating energy storage systems into industrial facilities offers numerous benefits while posing an array of challenges. From addressing financial hurdles and integration complexities to overcoming regulatory issues and establishing effective energy management strategies, facility operators must navigate a multifaceted landscape. Financial considerations remain at the forefront, as substantial upfront costs often dictate project feasibility. In tandem with this, the complexity of integration demands nuanced expertise in engineering and technical operations, necessitating careful planning and collaboration across all sectors involved.

Regulatory hurdles add yet another dimension of complexity, as compliance with laws and local standards can impede progress. Tailoring energy management strategies specific to each facility’s dynamic needs is crucial for deriving maximum benefit from these systems. Understanding and addressing these challenges will not only prove vital for individual industrial operations but will also contribute towards achieving wider sustainability and energy efficiency objectives. As industries increasingly pivot towards greener alternatives, energy storage systems will play an integral role in ensuring that these innovations are leveraged effectively to fuel sustainable industrial growth.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-challenges-of-retrofitting-industrial-facilities-with-energy-storage-systems/