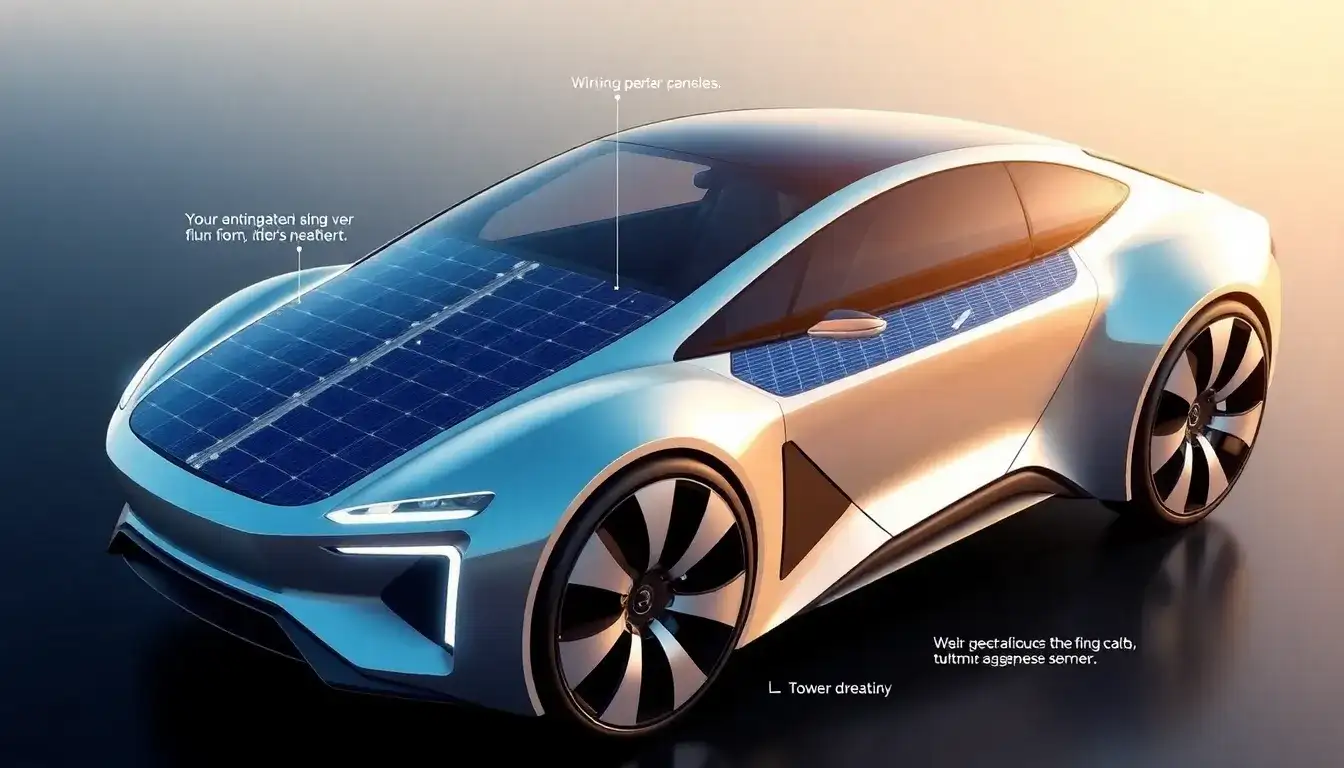

Thin-film solar panels present both opportunities and challenges for vehicle integration, particularly due to their flexibility and lightweight design. Here’s a breakdown of the primary challenges:

1. Power Generation Limitations

- Low energy density: Solar panels generate limited power per square meter, and vehicles offer restricted surface area. A typical car roof might produce only 250–500 watts under optimal conditions.

- Inefficient angles: Horizontal vehicle surfaces are suboptimal for sunlight capture compared to tilted rooftop installations.

- Shading issues: Partial shading (from trees, buildings, etc.) disproportionately reduces output due to cell interconnection challenges.

2. Technical and Structural Challenges

- Curvature mismatches: Vehicle roofs often have complex curves, leading to irradiance variations across cells and potential current mismatches.

- Durability concerns: Thin-film panels must withstand vibrations, impacts (e.g., hail), and UV degradation without compromising safety or aesthetics.

- UV resistance: Current flexible panels often use PET sheets with poor UV resistance, requiring improved materials.

3. Electrical Integration Complexities

- MPPT inefficiencies: Traditional maximum power point tracking (MPPT) systems struggle with rapid irradiance fluctuations caused by moving vehicles.

- Battery charging losses: High-voltage drivetrain batteries may experience transformation losses during solar charging.

- Safety protocols: Wiring and components must be waterproof, crash-resistant, and fail-safe to prevent electrical hazards.

4. Cost and Market Barriers

- Higher upfront costs: VIPV (vehicle-integrated photovoltaics) systems currently lack economies of scale, making them pricier than conventional alternatives.

- Repair complexity: Damaged panels require specialized maintenance without voiding vehicle warranties.

- Insurance hurdles: Custom insurance policies may be needed to cover PV-related repairs or theft.

5. Material and Environmental Factors

- Toxicity concerns: Cadmium in CdTe panels raises recycling and disposal challenges.

- Lifespan mismatch: Thin-film panels (10–20 years) may outlast some vehicle components, complicating lifecycle management.

Comparison of Key Challenges

| Challenge Category | Specific Issues |

|---|---|

| Power Generation | Low surface area, shading, suboptimal angles |

| Structural | Curvature, UV degradation, impact resistance |

| Electrical | MPPT adaptation, charging losses, safety |

| Economic | High costs, repair logistics, insurance |

| Material | Toxicity, lifespan, recyclability |

Innovations like parallel cell grouping (to mitigate shading losses) and advanced encapsulation materials are emerging solutions, but widespread adoption requires further R&D.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-challenges-in-integrating-thin-film-solar-panels-into-vehicles/