Benefits of Using Microencapsulated Mixtures in LHTES

1. Increased Heat Transfer Efficiency

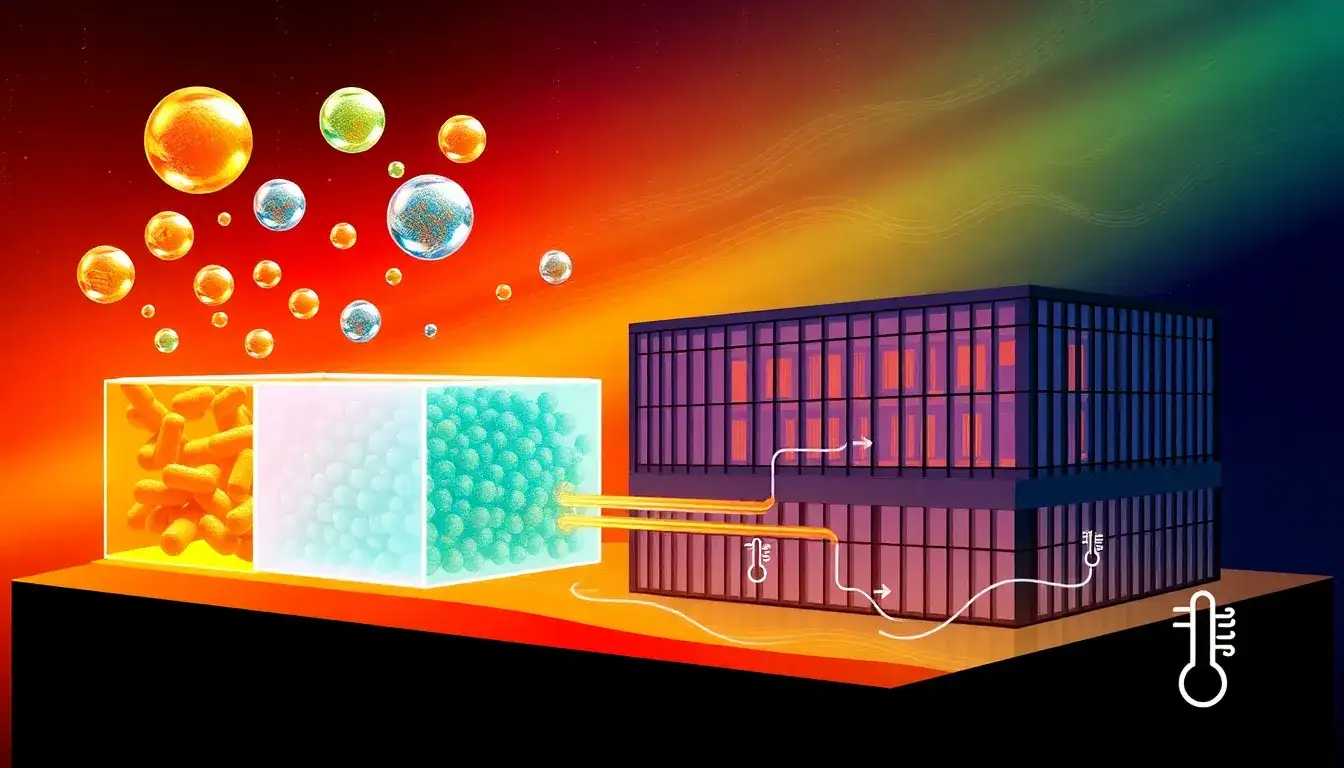

Microencapsulation creates small PCM particles, which greatly increase the surface area available for heat transfer per unit volume. This facilitates a higher heat transfer rate during the phase change process, improving the efficiency of thermal energy absorption and release.

2. Prevention of Leakage and Phase Separation

The microcapsule shell physically contains the PCM, preventing leakage of the molten phase during melting. This containment avoids phase separation and material loss, which are common issues in bulk PCMs, thereby enhancing durability and reliability over repeated thermal cycles.

3. Enhanced Mechanical and Thermal Stability

Microencapsulation provides mechanical protection to the PCM core, improving its robustness during operational stresses. The shell material can be engineered to withstand high temperatures and chemical interactions, extending the usable life of the thermal storage system.

4. Narrow Temperature Range for Energy Storage

Microencapsulated PCMs exhibit phase change within a narrow and well-defined temperature range, which allows for precise thermal management and better control in applications such as building climate systems or industrial heat recovery.

5. Compact and Versatile Form Factor

Due to their small size and containment, microencapsulated PCMs can be integrated into various matrices and materials such as building composites, polymers, or fluid suspensions. This versatility allows for a broader range of application options and easier system design.

6. Economic and Technical Feasibility for High-Temperature Applications

Innovations such as coating sodium nitrate particles with polyimide demonstrate that microencapsulated PCMs can be economically and technically viable for high-temperature thermal energy storage systems, maintaining performance while reducing costs.

In summary, microencapsulated mixtures in LHTES systems improve thermal performance by enhancing heat transfer rates, preventing leakage, increasing mechanical durability, maintaining a precise phase change temperature, enabling compact integration, and supporting cost-effective high-temperature storage solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-benefits-of-using-microencapsulated-mixtures-in-latent-heat-thermal-energy-storage/