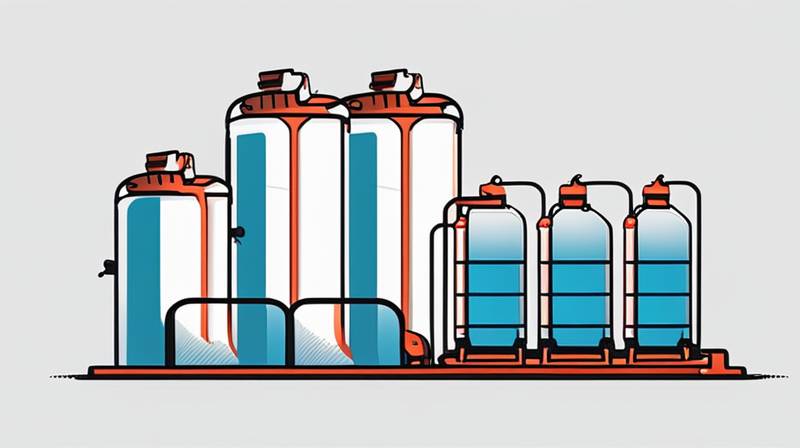

Steam storage tanks are essential components in various industrial applications, acting as reservoirs for accumulated steam. 1. They facilitate the efficient management of steam for heating and processing needs, ensuring consistent performance during peak demand times. 2. These tanks allow for load balancing, ensuring that steam generation meets the operational demands without the need for continual boiler operation. 3. Additionally, they help in energy conservation, enabling industries to use steam produced during off-peak hours for future needs. 4. Moreover, steam storage tanks contribute to improved system resilience, reducing potential downtime due to fluctuations in demand or supply interruptions, making them invaluable in sectors reliant on thermal energy.

1. FUNCTION AND UTILIZATION OF STEAM STORAGE TANKS

Understanding the operational role of steam storage tanks necessitates an exploration of how they function within various industrial scenarios. At their core, steam storage tanks serve as reservoirs that hold pressurized steam under controlled conditions, offering a strategic buffer in steam distribution systems. This aspect is pivotal in industries where steam acts as the primary medium for thermal energy transfer, such as food processing, power generation, and manufacturing. The functionality permits the smooth transition between steam generation and utilization, thereby preventing system strain during peak operational periods.

Moreover, these tanks serve a dual purpose in process optimization. Not only do they store steam, but they also contribute significantly to the effective distribution of heat across processes. In many industrial settings, the demand for steam can fluctuate dramatically, influenced by the operational schedule and production rates. By maintaining a reserve of steam, facilities can ensure continuous and efficient thermal output, irrespective of real-time generation capabilities. This capability not only enhances productivity but also promotes sustainability by minimizing energy wastage during points of low demand.

2. IMPACT ON ENERGY EFFICIENCY

The incorporation of steam storage tanks can directly correlate with energy efficiency improvements within an industrial setup. As energy costs rise, industries are increasingly seeking ways to optimize their consumption patterns, and steam storage systems provide a valuable solution. During off-peak times, when energy costs are lower and production demands decrease, steam can be generated and stored for later use. This strategic delay in consumption not only manages costs effectively but also aligns with modern sustainability initiatives aimed at reducing carbon footprints.

Additionally, the system prevents inefficient operations. Without a steam storage solution, companies would need to operate their boilers continuously at full capacity to meet even sporadic demands. This approach leads to excessive fuel consumption and increased emissions, undermining environmental goals. By allowing plants to run boilers during optimal conditions, steam storage tanks actively support cleaner, more efficient operations, which is increasingly crucial as industries face rigorous sustainability regulations.

3. DESIGN AND TECHNOLOGY CONSIDERATIONS

The design of steam storage tanks is paramount to their efficiency and effectiveness. Various factors must be considered in this design process, including tank size, material composition, and insulation type. The size of the tank plays a critical role, as it must be adequate to accommodate the volume of steam necessary to meet operational demands without excessive cycling. Oversized tanks lead to increased material and energy costs, while undersized tanks can result in production bottlenecks. Thus, achieving the correct sizing is essential for optimal function.

Material selection is another critical aspect. Tanks must be constructed from materials capable of withstanding high pressures and temperatures associated with steam storage. Common choices include carbon steel, stainless steel, and composite materials, each offering different benefits depending on the operating environment and specific application. Additionally, the insulating properties of the tank must be crafted to minimize heat loss, preserving energy and maintaining operational efficiencies over shorter periods.

4. MAINTENANCE REQUIREMENTS AND BEST PRACTICES

To ensure longevity and performance reliability, routine maintenance of steam storage tanks is requisite. Preventive maintenance practices mitigate the risk of failures and costly repairs that can emerge from neglect. Regular inspections should include checks for signs of corrosion, pressure integrity, and operational efficiency. By establishing a routine, industries can detect potential issues before they escalate.

Implementing best practices for maintenance can significantly enhance tank durability. For instance, regular cleaning schedules can prevent sediment buildup that may affect heat transfer efficiency. Furthermore, systems should be in place for monitoring the internal and external conditions of the tank continuously. This includes pressure gauges, temperature sensors, and automated data logging systems to observe performance trends.

5. APPLICATIONS ACROSS INDUSTRIES

Steam storage tanks are versatile, finding applications in diverse industries beyond the initial examples. In chemical processing, for instance, they ensure that steam is readily available for various reactions, fostering consistent product quality and increased throughput. By having steam on demand, chemical plants can maintain precise control over reaction conditions, which is critical in processes where temperature fluctuations can yield significant product variation.

Additionally, in the renewable energy sector, particularly in concentrated solar power systems, steam storage tanks play a pivotal role. They allow for the storage of thermal energy generated during sunlight hours, which can then be utilized during periods of low sunlight or high energy demand. This capability supports grid stability and energy delivery, integrating renewable energy generation into traditional power systems more seamlessly.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF STEAM STORAGE TANKS EXIST?

Various designs and types of steam storage tanks exist to accommodate different industrial requirements. The two primary types include insulated and non-insulated tanks. Insulated tanks are designed to minimize heat loss, maintaining steam at desired temperatures for extended periods. They are typically used in applications where long-term storage is necessary. Non-insulated tanks are employed when immediate usage of steam is anticipated, making thermal retention less critical. Furthermore, tanks can vary in size, materials, and configurations based on operational needs, with some designed for high-pressure environments and others for lower pressure setups. Understanding the specific requirements of a facility will dictate the appropriate choice of steam storage tank to maximize efficiency and ensure proper functioning.

HOW DOES STEAM STORAGE IMPROVE OPERATIONAL EFFICIENCY?

The presence of steam storage tanks markedly enhances operational efficiency in several ways. By storing steam generated during lower demand periods, industries can optimize energy use and reduce costs associated with fuel consumption. This stored steam can then be utilized during high-demand phases without overworking boilers, thus preventing wear and promoting longevity. Furthermore, the flexibility afforded by steam storage facilitates a more stable production process, minimizing downtime caused by fluctuations in steam availability. By ensuring a steady supply of steam irrespective of generation conditions, facilities can maintain consistent quality in products and processes, thus boosting overall operational productivity.

WHAT ARE COMMON CHALLENGES WITH STEAM STORAGE TANKS?

While steam storage tanks provide numerous benefits, they also come with challenges. One common issue is the risk of temperature stratification, where layers of steam at various temperatures can form, leading to inefficiencies in usage. This condition can limit the effectiveness of the stored steam, requiring enhancements in design or operational practices to counteract the phenomenon. Additionally, ensuring safety during operation is paramount, as the high pressures involved can pose risks if not properly managed. Regular inspections and adherence to safety protocols are essential in addressing these challenges. Finally, factors such as corrosion and sediment buildup can impact the performance of storage tanks, necessitating proactive maintenance measures to sustain efficiency and reliability.

The exploration into the utility of steam storage tanks reveals their critical role across various industrial sectors. Their significance emerges not just through steam management, but also in their contribution to energy efficiency, operational stability, and sustainability efforts. As industries continue to seek innovative ways to optimize energy consumption and production processes, the demand for effective steam storage solutions is anticipated to grow significantly. Consequently, understanding the nuances associated with their design, maintenance, and application becomes imperative for stakeholders involved in thermal energy systems.

Emphasizing the importance of regular maintenance cannot be overstated. Facilities equipped with steam storage tanks must recognize the potential pitfalls of neglect, which can lead to decreased efficiency and increased operational costs. Proactively addressing potential issues through scheduled inspections and maintenance can prolong the life of the system and enhance overall productivity. Furthermore, as industries evolve and adapt to new technologies and standards in energy management, steam storage tanks will remain at the forefront, essential for meeting thermal energy demands while also contributing to long-term sustainability goals.

In summary, steam storage tanks embody the intersection of utility and innovation. Their strategic function within industrial operations underpins not only cost-saving initiatives but also supports a broader commitment to energy stewardship and operational excellence. As dependence on thermal energy persists, the critical analysis of steam storage technology will ensure that industries can harness its full potential, paving the way for enhanced productivity in the years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-steam-storage-tanks-used-for/