Understanding the process of disassembling a solar light cord involves several key steps that can streamline maintenance and repairs. 1. Tools required, 2. Safety precautions, 3. Step-by-step instructions, 4. Common issues encountered. Disassembling a solar light cord is essential for troubleshooting malfunctions or replacing damaged components, ensuring the longevity of solar lighting systems.

1. TOOLS REQUIRED

Engaging with projects such as disassembling solar light cords necessitates having the appropriate tools on hand. Essential tools commonly include screwdrivers, pliers, and sometimes a multi-tool. A Phillips head screwdriver is particularly useful as many solar lights utilize screws of this type in their construction. Pliers can assist in gripping and pulling apart components, while a multi-tool adds flexibility by providing various functions in one device. Additionally, using a pair of wire cutters may become necessary if electrical connections need to be severed, particularly in cases where replacement components are to be integrated.

However, having tools is only part of the equation. Ensuring that these tools are in good working order significantly enhances the effectiveness of the disassembly process. Dull screwdrivers can strip screws, making it more challenging to access the internal parts of the solar light cord. In more advanced setups, specialized tools might be required, such as a voltage tester to ensure safety when handling electrical components. Preparation with the right tools can save considerable time and effort during disassembly.

2. SAFETY PRECAUTIONS

Prior to initiating the disassembly of a solar light cord, taking safety precautions is imperative. Solar lights contain electrical circuits that, if mishandled, can lead to shocks or injuries. It is essential to always handle solar lights turned off. Removing the batteries beforehand also reduces the chances of accidental discharges. After ensuring the lights are powered down, wearing safety goggles is advisable to protect one’s eyes from potential debris that may dislodge during the disassembly process.

Another important consideration involves working within a well-lit environment. Visibility can significantly affect the precision of the disassembly, making it easier to identify and navigate screws and clips. Having adequate light not only assists with identifying components but also helps in recognizing any potential risks associated with the task. A clean workspace also contributes to a safer experience by minimizing clutter and potential distractions. Overall, taking such precautions will ensure a smoother process.

3. STEP-BY-STEP INSTRUCTIONS

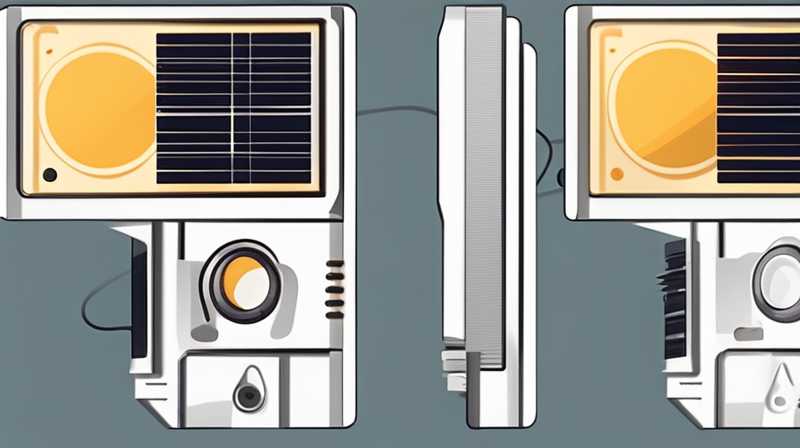

Disassembling the solar light cord follows a structured sequence designed to maximize efficiency and minimize damage. Initially, detach the solar panel from the unit. Usually, this involves unscrewing the panel from its holder, allowing easier access to the wiring. The wires leading from the solar panel are typically secured with clips; gently prying these open can facilitate removal without damage. Once the solar panel is off, attention turns to the light itself.

Next, focus on the casing surrounding the light bulb. Carefully remove the screws securing the casing to avoid breakage or misplacement. In many solar lights, the casing is molded, which may require additional care during removal. Keep track of all screws and components throughout the process to avoid confusion when reassembling. If the wiring within the casing needs to be accessed, ensure appropriate handling, as pinched or frayed wires can disrupt functionality. At this stage, troubleshooting can begin to determine whether any issues exist with the electrical components or if a simpler fix, like replacing a bulb, is all that is required.

4. COMMON ISSUES ENCOUNTERED

During the disassembly process, specific issues may arise that can complicate the procedure. One common challenge involves stripped screws that resist removal. In such cases, a rubber band can be utilized between the screwdriver and screw head, providing additional grip to facilitate extraction. For screws that are completely stuck, penetrating oils can help loosen them, emphasizing the need for patience and care during the process.

Another prevalent problem pertains to damaged wiring or connections once the internal components are accessed. Corrosion, frayed wires, or disconnected components can often cause solar lights to malfunction. Before reassembling the unit, meticulous inspection of wiring should be conducted to identify any possible repairs needed. Replacing wires or soldering connections when necessary ensures that the solar light will function correctly once reassembled. Addressing such issues effectively will contribute to the overall lifespan and operational integrity of the solar lighting system.

FAQs

HOW CAN I TELL IF MY SOLAR LIGHT CORD IS FAULTY?

To determine if your solar light cord is faulty, observe multiple aspects of its performance. Begin with the solar panel, ensuring it receives adequate sunlight and is free from obstructions. A dirty or shadowed panel can misrepresent the functionality of the entire system, leading to diminished energy collection. Examine whether the LED bulb lights up when darkness falls; if it does not, potential issues with the battery or wiring may exist. In such cases, inspecting the connections for corrosion or damage is crucial, as these can disrupt electrical flow. Testing the solder connections on the LED and the battery can also yield insights into possible faults.

Moreover, check the battery voltage using a multimeter. Ideally, the battery should hold a charge well above 1.2 volts; significantly lower readings suggest that replacement is necessary. Equally important, a thorough inspection of the wiring can reveal frays or breaks, indicating repair requirements. If essential components show signs of wear, replacing them promptly can restore functionality and longevity to the solar unit. Fostering a proactive approach to inspections will ensure the solar lighting system performs at its best.

WHAT TYPES OF SOLAR LIGHTS CAN BE DISASSEMBLED?

The disassembly of solar lights can vary based on their design. Generally, solar garden lights, pathway lights, and accent lights can be taken apart for maintenance or repair. Each type features different mechanisms, but the overarching principles of disassembly remain similar. Some models come with simpler configurations, enabling easier access to components, whereas others may boast more intricate designs, requiring greater dexterity and tool familiarity.

Understanding the unique features of the specific model can enhance the disassembly experience. For example, string lights made of solar components often require removal of screws along the line, while stand-alone fixtures might only need unscrewing the light housing and accessing internal circuitry. Familiarizing oneself with the individual model prior to conducting the procedure will allow for better preparedness and a higher likelihood of success. With various types available, knowing the disassembly process increases the ability to effectively maintain and repair different solar light systems.

CAN I REPLACE COMPONENTS IN SOLAR LIGHT CORDS?

Yes, replacing components in solar light cords is feasible, provided the correct parts are sourced. The most commonly replaced components include bulbs, batteries, and wiring. When bulbs burn out, finding a suitable replacement is essential. Many solar lights use standardized bulb types, making it easier to source new ones at hardware stores or online. When it comes to batteries, opting for rechargeable varieties specifically designed for solar use ensures that the system operates effectively.

Replacing wiring can be slightly more complex as this often necessitates some soldering skills or the use of connectors. Inspecting the wiring’s condition allows for timely replacements, saving the overall light functionality from being compromised by deteriorating connections. Should specific components seem irreparable, asserting the purchase of compatible replacements based on the manufacturer’s specifications is vital to ensure proper integration. Thus, actively sourcing and replacing components extends the life of the solar lighting system and enhances performance outcomes.

Bolded and underscored recapitulation can be made effective through ensuring the solar light system is maintained adequately. Proper care can also maximize the operational longevity and help avoid complex issues over time.

In summary, a comprehensive understanding of the disassembly process results in effective troubleshooting, maintenance, and repairs for solar light cords. Maintaining this knowledge proves beneficial for efficient handling of common issues, ensuring every part of the solar light system operates optimally. Engaging in proactive inspections and replacements of faulty components ultimately enhances the longevity and effectiveness of solar lighting products, contributing to a sustainable and practical approach to outdoor illumination.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/video-of-how-to-disassemble-solar-light-cord/