1. SOLAR INSTALLATION TUTORIAL: HOW TO INSTALL PIPES

To successfully install pipes for a solar energy system, one must follow specific methodologies. The process includes 1. Evaluating site requirements, 2. Selecting appropriate materials, 3. Installing mounting structures, and 4. Ensuring proper insulation and sealing. A thorough understanding of local building codes and standards is essential to avoid pitfalls during installation.

2. UNDERSTANDING THE IMPORTANCE OF PIPE INSTALLATION IN SOLAR ENERGY SYSTEMS

The role of pipes in solar energy systems cannot be overstated. They are responsible for transporting fluids—usually water or antifreeze solutions—between solar collectors and storage tanks. Properly designed piping systems not only enhance efficiency but also contribute significantly to the longevity of the entire system. Heat transfer is largely dependent on the type of pipes utilized which influences the overall performance of solar thermal installations.

When considering pipe installation, one must assess various factors. Ambient conditions, including temperature fluctuations, play a pivotal role. Choosing the right materials, such as copper or PEX, depends on whether the installation is indoor or outdoor. Copper is renowned for its durability and conductivity, while PEX provides greater flexibility and is resistant to corrosion. Contemplating the pros and cons of each material is critical in selecting the most suitable options for a given installation.

Furthermore, the diameter of the pipes should facilitate optimal flow rates. Larger diameters can reduce resistance to flow, whereas smaller ones might necessitate increased pressure, consequently escalating energy consumption. Calculating the required flow rate accurately minimizes energy losses and promotes the efficacy of the system.

3. PREPARING FOR PIPE INSTALLATION

Preparation sets the foundation for a successful solar pipe installation. One must initiate the process by conducting a meticulous assessment of the site’s conditions and requirements. Perform a comprehensive inspection of the area, considering factors such as direction of solar exposure, existing landscapes, and proximity to storage tanks. Such detailed evaluations inform the installation strategy.

An essential aspect of preparation lies in the acquisition of necessary permits and adherence to local building codes and regulations. Different regions have varying prerequisites; hence, understanding these regulations can facilitate a smoother installation process and mitigate the risk of future issues. In some cases, consultations with local authorities can provide clarity on specific requirements.

4. SELECTING THE RIGHT COMPONENTS

They play a vital role in the successful functioning of solar energy systems. The selection of components extends beyond just pipes. A well-rounded approach involves choosing compatible fittings, connectors, and valves that will withstand environmental conditions and ensure a robust system.

When selecting fittings, ensure they align with the chosen pipe material. Employing improper fittings can lead to leaks and, subsequently, a drop in system efficiency. Additionally, quality connectors expedite the assembly process while assuring leak-proof joints. It is prudent to opt for branded components, as they generally offer greater reliability.

Insulation is another crucial component in this process. Proper insulation prevents heat loss during the transit of fluids through the pipes. Without adequate insulation, energy efficiency diminishes significantly, resulting in a higher operational cost. In colder climates, insulating all pipes, especially those located outdoors or in unheated spaces, is non-negotiable.

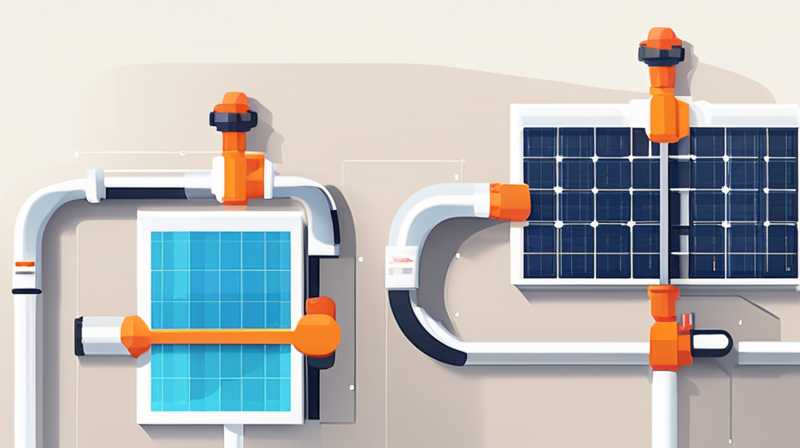

5. INSTALLING MOUNTING STRUCTURES

Before commencing the installation of pipes, an individual’s focus should encompass the mounting structure of the solar collectors. This support system acts as the backbone of the installation, ensuring that collectors maintain optimal angles for sun exposure throughout the day.

Selecting an appropriate mounting structure involves considering geographic locations and the anticipated weather patterns. For instance, fixed mounting systems may suffice in areas with stable weather, whereas adjustable or tracking systems might be more suitable for regions with variable climates. Nonetheless, while more complex, tracking systems can significantly increase energy production.

Also, follow rigorous standards while ensuring secure fastening of the mounts. This step prevents system failures due to wind or structural stresses. Prior to pipe connections, the correct orientation and alignment of collectors must be verified to enhance performance efficiency.

6. PIPE INSTALLATION PROCESS

With preparations and component selections completed, attention turns to the actual pipe installation. Begin by laying out the routes that the pipes will traverse. This step often involves working around existing structures and avoiding obstacles. Marking the intended pathway prior to installation helps visualize the entire process and reduces errors.

Upon marking, proceed to cut the pipes to the desired lengths. Precision in cutting is paramount; irregularities can lead to improper fittings and potential system leaks. Additionally, clean the ends of each pipe thoroughly—debris left on the ends can compromise the integrity of connectors, leading to compromised connections.

Fastening the pipes securely is the next step. Ensure that all connections are tight while avoiding over-tightening which may lead to material fatigue. Following this, rigorously inspect every joint, looking for signs of leakage or misalignment.

7. ENSURING PROPER INSULATION AND SEALING

Once pipes are installed, it becomes vital to focus on insulation and sealing. Poor insulation not only leads to substantial energy losses but also increases the risk of freeze damage in colder climates. Use foam or fiberglass insulation to encase pipes, paying particular attention to bends and joints.

Sealant application at joint points is critical as well. Employ high-quality sealants formulated for outdoor use, ensuring lasting protection against moisture infiltration. Carefully inspect the insulated sections, as sagging may occur if not adequately adhered, thereby exposing the pipes to elements.

8. TESTING AND MAINTAINING THE SYSTEM

After installation, comprehensive testing is crucial to verify the entire system’s integrity. Start with a pressure test to detect leaks within the piping system before initiating any fluid movement. This procedure involves closing all outlets and introducing air pressure to assess for any structural weaknesses throughout the plumbing. Observing pressure gauges closely aids in addressing potential issues before they escalate.

Following the pressure test, initiate a water flow test, scrutinizing all connections for leaks during operation. Precautionary measures should include a continuous inspection over the initial days of system operation to detect any anomalies swiftly. Regular maintenance is indispensable for the longevity and efficiency of the entire system.

During operation, establish a routine maintenance schedule that includes checking fluid levels, inspecting for leaks, and ensuring insulation remains intact. Periodic assessments preserve system health and facilitate early identification of components requiring replacement.

9. ADDITIONAL CONSIDERATIONS AND TIPS

Several other factors contribute to efficient pipe installation for solar systems. Considerations such as local climate, expected energy requirements, and future scalability should inform planning. Not all systems require identical setups; personalization based on unique circumstances can yield significant results.

Networking with professionals or local solar installation companies can enrich one’s understanding of best practices. Such connections provide insights into varying experiences that can ultimately improve installation quality. Attending workshops or educational events related to solar technology enhances knowledge and equips installers to tackle unique challenges confidently.

It is prudent to conduct post-installation evaluations. After a certain period, returning to assess the efficiency of the overall installation provides valuable feedback on potential enhancements. Documenting each system’s performance can guide future installations and amplify knowledge within the solar energy community.

FAQs

WHAT MATERIALS ARE BEST FOR SOLAR PIPE INSTALLATION?

Selecting materials for solar pipe installations necessitates a blend of durability, efficiency, and environmental conditions. Copper is frequently lauded for its excellent thermal conductivity and longevity, making it a popular choice for many installations. However, it may come at a higher price and is prone to corrosion if not adequately managed. PEX (cross-linked polyethylene) has gained popularity for its flexibility and resistance to scale and chlorine, making it ideal for residential installations. Choosing between these materials largely depends on budget constraints, geographical climate, and personal preferences regarding efficiency and longevity. Important considerations include pipe diameter, where larger sizes can allow for greater energy efficiency by minimizing resistance to fluid flow. Evaluating local plumbing codes and consulting with seasoned professionals can guide this decision further, ensuring optimal choices tailored to individual installation needs.

HOW DO I MAINTAIN SOLAR PIPE SYSTEMS AFTER INSTALLATION?

Maintenance of solar pipe systems post-installation is vital in safeguarding performance and longevity. Regularly checking for leaks or wear provides an initial step in preserving integrity. Insulation must remain intact, as poor insulation can lead to heat loss, diminishing system efficiency. Periodic inspections of joints and valve functionalities help prevent operational declines. A systematic approach involves establishing a maintenance schedule that includes cleaning the collector panels, checking fluid levels, and inspecting for potential freeze damage during colder seasons. Environmental changes should prompt evaluations of the surrounding landscape, ensuring no growth encroaches upon the system. Consulting experienced installers or maintenance services can bolster this maintenance routine, leading to optimal performance and extending operational life. Gathering data on performance metrics can help assess efficiency trends over time, prompting timely adjustments or repairs as necessary.

WHAT COMMON MISTAKES SHOULD BE AVOIDED DURING PIPE INSTALLATION?

During the installation of pipes in solar energy systems, several missteps can compromise performance. Insufficient planning or failure to account for local conditions can lead to inadequacy in flow rates, resulting in energy losses. Skipping pressure testing post-installation allows leaks to go undetected, causing eventual failures affecting the entire system. Additionally, the use of incompatible materials for fittings or connectors may result in leaks or premature wear. Neglecting insulation or improper application can leave systems vulnerable to temperature fluctuations, leading to energy inefficiencies. Adhering to local building regulations is also critical; ignoring this can yield penalties and installation rejections. Engaging with experienced professionals or attending workshops can mitigate these risks, ensuring that installations meet or exceed performance expectations. Careful consideration and education regarding these common pitfalls will lead to a more resilient and effective solar piping system.

10. FINAL THOUGHTS ON SOLAR PIPE INSTALLATION

Solar pipe installation requires thoughtful consideration of various elements to ensure efficiency and longevity. This necessitates both adequate preparations and skilled execution. Understanding the importance of material selection, installation techniques, and ongoing maintenance cannot be overstated. Each aspect has ramifications on the system’s operational integrity and energy production capabilities. Proper assessments before installation, coupled with informed choices on components and methods, set the foundation for a successful setup. Ongoing evaluations and adjustments, grounded in performance metrics and feedback, allow for optimization over time. The full scope of considerations ranges from the local climate environment to the specific design choices addressed throughout the installation process. Ultimately, taking the time to approach each step with care enhances not only the performance but also the overall sustainability of the solar energy system, enticing many to harness the power of solar energy effectively. Investing in quality materials, consulting professionals, and adhering to best practices gain significance in the long-term success of solar energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/solar-installation-tutorial-how-to-install-pipes/