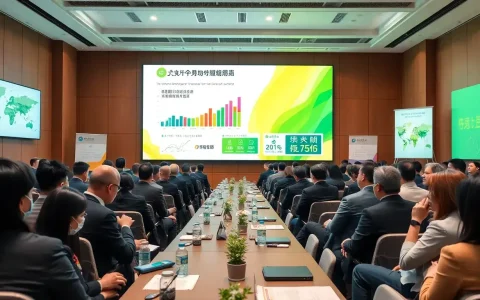

The SNEC 2025 PV&ES Expo, held at the National Exhibition and Convention Centre in Shanghai, China, concluded successfully, attracting over 3,600 companies and industry professionals from almost 100 countries. This year’s event also set a record with an exhibition space of 400,000 square meters. However, the industry faces significant challenges outside the exhibition hall. Polysilicon prices have fallen to RMB 34,500 per ton (approximately US$4,803 per ton), and more than half of publicly listed PV companies have reported losses for five consecutive quarters. As a result, the entire sector is at a critical juncture, grappling with the need to balance “scale expansion” with “value creation.”

As the largest PV exhibition globally, SNEC serves as an excellent platform to observe how companies are adapting in response to the industry’s downturn. This year, TOPCon modules showcased efficiencies exceeding 26%, while perovskite tandem cells entered pilot production. Back contact (BC) technology is evolving into lightweight dual-protection modules, prompting companies to rethink strategies that shift from “price wars” to “long-term survival.” Jinko Solar’s Chairman, Li Xiande, emphasized the need to focus on “revival” rather than merely surviving, while GCL-SI’s Chairman, Zhu Gongshan, noted that the “ice age” of the industry will eventually end, and the true survivors will be those capable of “scenario-defining” and “ecosystem-integrating.”

### N-type TOPCon Divergence and High-Performance Modules

This year’s module offerings have fully transitioned to N-type technologies, with distinct factions emerging among TOPCon, HJT, and BC technologies. N-type modules, paired with perovskite technology, are achieving breakthroughs in both high power and efficiency. Companies have introduced several high-output modules, including Huasun Solar’s HJT-perovskite tandem G12 module that reaches 800W, Astronergy’s ASTRO N8 Pro module which also exceeds 800W, and Tongwei’s THC module at 790.8W.

TOPCon technology has become the flagship product for many manufacturers, with many exhibitors presenting TOPCon-perovskite tandem modules that push power levels higher. Jinko Solar’s Vice President, Qian Jing, stated that the market is set to segment, with 650W modules establishing a new benchmark. Manufacturers capable of mass-producing these will command premium prices, competing with BC technologies in distributed generation markets, while sub-650W products will likely remain mainstream.

### The Rise of Back Contact Technology

In the realm of BC technology, there is a prevailing sentiment that “mass production can wait,” with manufacturers eager to showcase their latest innovations. Notable players like Aiko Solar and LONGi have generated considerable excitement with their advancements. Aiko Solar revealed its fully upgraded ABC module portfolio, which is tailored for various applications, including residential and commercial installations. Their third-generation “Full-Screen” ABC module, featuring 54-cell, 72-cell, and 78-cell variants, can produce output between 800W and 810W, achieving up to 25% conversion efficiency.

LONGi Green introduced its Hi-MO X10 lightweight dual-protection module, designed for low-load commercial and industrial rooftops, and reported that this module is 30% lighter than traditional products, addressing the challenge of underutilized rooftops due to inadequate load-bearing capacity.

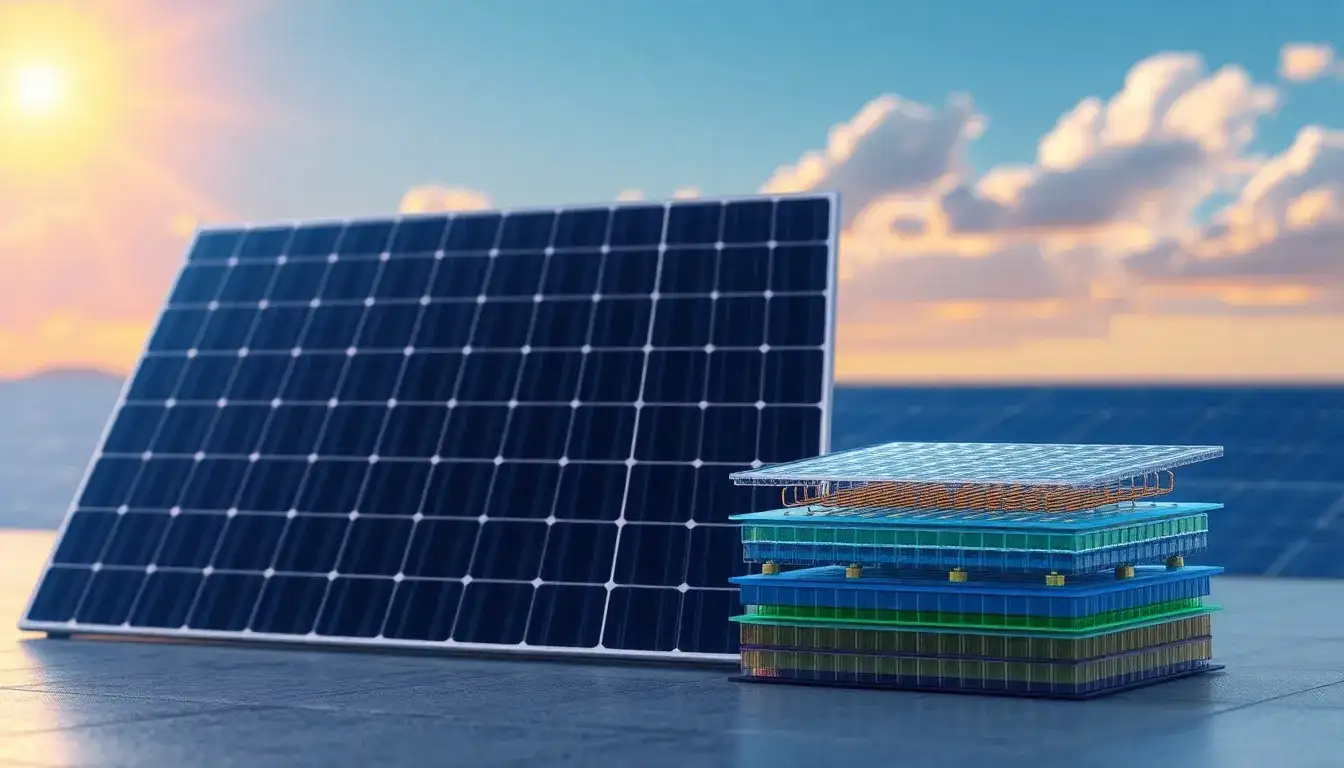

### The Dawn of Perovskite Tandem Cells

Beyond mainstream N-type products, SNEC also highlighted differentiated offerings, including thin-film flexible modules, BIPV products, and balcony PV systems. These products are slowly carving out niches, although predicting future frontrunners remains challenging. Trina Solar’s Chairman, Gao Jifan, believes that the industry’s debate over the superiority of TOPCon, BC, or HJT technologies is futile. He asserts that the emergence of perovskite tandem cells marks a transformative phase for the industry.

Trina Solar plans to establish a perovskite pilot production line, aiming for a minimum efficiency improvement of 4% over conventional crystalline-silicon modules. The company recently announced it achieved a 30.6% efficiency for a perovskite-silicon tandem module, certified by the Fraunhofer Institute for Solar Energy Systems (ISE) in Germany. Similarly, GCL-SI’s Chairman noted that perovskite tandem modules could potentially offer 50% higher theoretical efficiency and reduced costs, estimating that 1GW of such modules could generate an additional RMB 2 billion in revenue over their lifecycle.

At the GCL Tech booth, the company showcased multiple products, including a 2 m² perovskite single-junction module with a conversion efficiency of 19.04% and a tandem module achieving an efficiency of 26.36%. These large-format modules have reached cost-efficient mass production, with manufacturing costs approximately half that of conventional crystalline-silicon modules. A representative from GCL Tech remarked that perovskite has entered an era characterized by “high efficiency, large size, and stability.”

Jinko Solar also announced that its N-type TOPCon-perovskite tandem cell achieved a record conversion efficiency of 34.22% and exceeded 2.01V, certified by a third-party Voc assessment. Furthermore, their tandem cells have demonstrated exceptional reliability, maintaining less than 5% efficiency degradation in multiple tests, thus setting new industry benchmarks.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/snec-2025-highlights-advancements-in-800w-modules-n-type-technology-and-perovskite-tandem-innovations/