Pioneering Advances in Battery Technology

From laptops to electric vehicles, lithium-ion batteries play a crucial role in our daily lives. However, the rising demand for longer-lasting devices threatens to outpace the energy supplied by traditional lithium-ion batteries. To address this challenge, researchers are actively seeking more powerful battery solutions.

A team led by Kelsey Hatzell, an associate professor of mechanical and aerospace engineering at Princeton University and a member of the Andlinger Center for Energy and the Environment, has made significant strides toward developing a new type of battery known as an anode-free solid-state battery. This research aims to push beyond the limitations of lithium-ion technology.

Hatzell emphasizes the potential of these advanced batteries: “If we can successfully introduce these emerging technologies, we could achieve energy densities that are impossible with conventional batteries. This would mean that your laptop and phone could last longer on a single charge, electric vehicles could travel over 500 miles, and we might even see advancements in electrified aviation.”

This research is part of Hatzell’s role as a manufacturing leader in the Mechano-Chemical Understanding of Solid Ion Conductors (MUSIC), an Energy Research Frontier Center supported by the U.S. Department of Energy. MUSIC, led by the University of Michigan at Ann Arbor, brings together 16 faculty members from nine institutions, including Princeton University.

Jeff Sakamoto, an energy storage expert and director of MUSIC, notes that while solid-state batteries have the potential to revolutionize energy storage technology, a significant challenge remains: developing a scalable manufacturing process. “Hatzell’s work is crucial in improving the solid-state manufacturing process,” Sakamoto explains. “Her collaboration with MUSIC exemplifies how integrated research can tackle complex, multidisciplinary challenges.”

Understanding Battery Mechanics

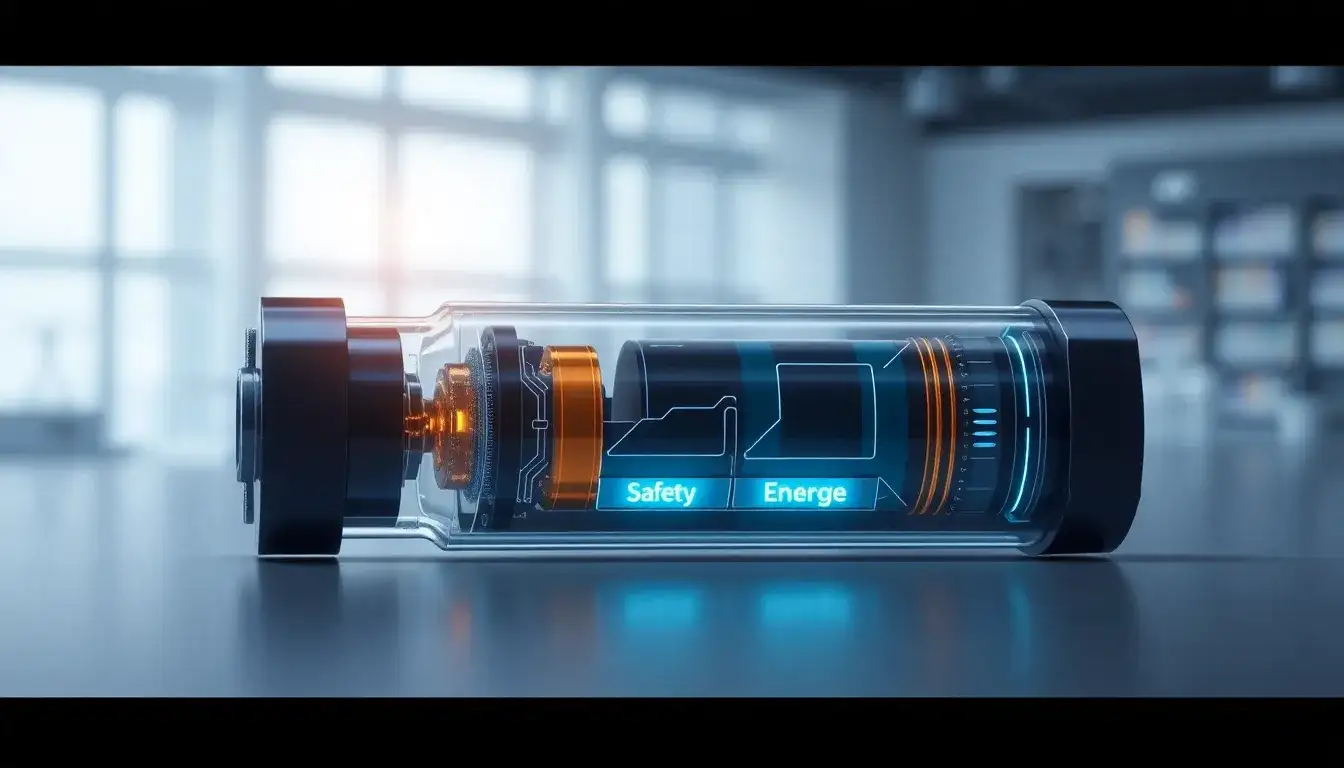

Traditional batteries consist of two electrodes: a positive electrode (the cathode) and a negative electrode (the anode). Each electrode is connected to a thin metal foil called a current collector, and the two electrodes are separated by an electrolyte. The movement of ions between these electrodes powers the battery. When charging, ions flow from the positive electrode to the negative one through the electrolyte, and this flow reverses during discharging.

In contrast to conventional lithium-ion batteries, the anode-free solid-state batteries that Hatzell’s team studies differ in two fundamental ways:

- Solid Electrolyte: Instead of a liquid electrolyte, these batteries use a solid electrolyte, allowing for more energy storage in a smaller space. This characteristic enables longer driving ranges for electric vehicles and enhances performance across a wider temperature range while promising greater durability.

- Anode-Free Design: In anode-free batteries, the negative electrode is eliminated. Instead, ions flow directly from the positive cathode to the current collector, where they form a thin metal layer as the battery charges. This design reduces costs and size, avoiding the need for specialized manufacturing associated with lithium metal foils typically found in standard solid-state batteries.

Hatzell explains, “By assembling a battery without a lithium metal anode, we can significantly reduce costs while utilizing existing manufacturing processes, both of which are essential for making a meaningful impact in the battery market.”

Overcoming Challenges

Despite their promising advantages, next-generation batteries face several challenges. One key issue is ensuring good contact between the solid electrolyte and the current collector, which is crucial for even ion deposition during charging and discharging.

In a paper published on February 22, Hatzell and her team, including first author Se Hwan Park, a postdoctoral researcher, examined how factors such as applied pressure affect this contact. “During charging and discharging, the battery undergoes electrochemical reactions, and applying external pressure introduces mechanical forces,” noted Park. “It’s a complex system with many interacting variables.”

Unlike the liquid electrolytes in traditional batteries, solid electrolytes are rigid. Any surface defects on the electrolyte or current collector can hinder their contact quality. The researchers found that low pressures failed to improve uneven contact, causing ions to deposit and strip unevenly, leading to the formation of sharp metal filaments that could pierce the solid electrolyte and short-circuit the battery. Conversely, high pressures promoted better contact but also magnified imperfections, leading to fractures.

Hatzell explained that both low and high pressures could lead to battery failure for different reasons, providing valuable insights into how to optimize the manufacturing and operation of anode-free solid-state batteries. “The goal is to maintain solid contact at low pressures, as creating a defect-free electrolyte is nearly impossible,” she stated.

Finding Solutions

While their findings underscored the importance of achieving even contact, Hatzell’s group also explored potential solutions in a separate paper published on December 19. They demonstrated that introducing a thin coating, called an interlayer, between the current collector and the electrolyte could facilitate better ion transport and achieve more uniform ion plating and stripping.

The team tested various interlayer materials, finding that those made from carbon and silver nanoparticles were most effective. The silver formed alloys with ions during battery operation, enabling consistent plating and stripping from the current collector. However, the size of the silver nanoparticles proved crucial; larger particles led to less stable, uneven metal structures that compromised battery durability. Smaller particles resulted in denser, more uniform structures, enhancing stability and power output.

Park elaborated on the significance of their findings: “Only a few research groups have investigated the processes occurring in these interlayers. We showed that the stability of these systems is closely linked to the morphology of the metal during plating and stripping.”

Looking Ahead

In addition to their experimental work, Hatzell and her MUSIC collaborators reviewed the current state of anode-free solid-state batteries in a paper published on January 2. They summarized recent advancements and identified critical research gaps, particularly the challenge of scaling successful lab techniques for incorporation into existing battery manufacturing processes.

Hatzell expressed optimism about the future: “Countries like Japan and South Korea are now making plans to bring solid-state batteries to market. For instance, Samsung aims to mass-produce these batteries by 2027, and Toyota has set a target for 2030.”

“The key challenge will be translating research findings into real-world applications within the next few years,” Hatzell concluded. “We hope that our ongoing work at MUSIC will support the development and deployment of these next-generation batteries at a significant scale.”

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/revolutionizing-energy-storage-breakthroughs-in-anode-free-solid-state-battery-technology/