Recommended Brands for Automatic Palletizing Robots: Analysis of Mainstream Manufacturers and Technical Approaches

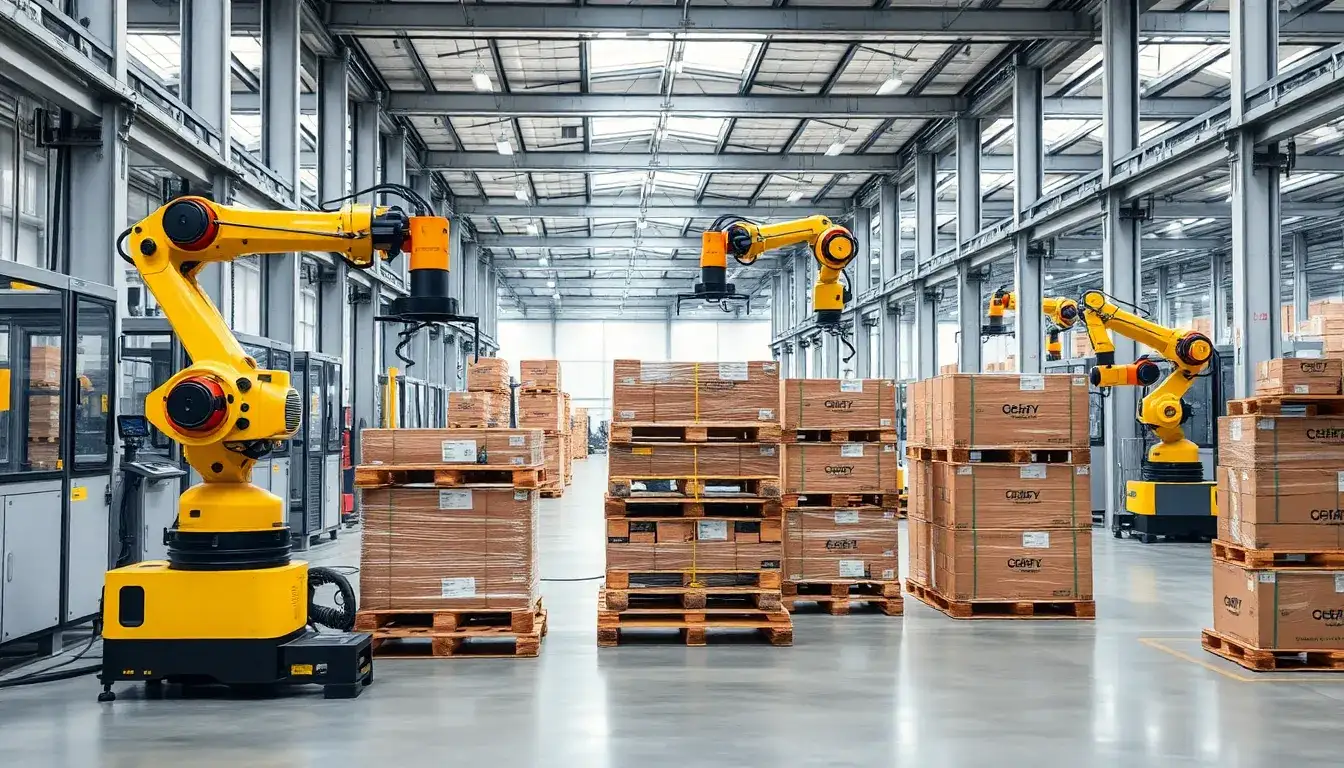

In industries such as food and beverage, daily chemicals, pharmaceuticals, and new energy, automatic palletizing robots have become essential equipment at the end of production lines. When discussing “recommended brands for automatic palletizing robots,” it’s important to note that there is no single standard answer. The value of different brands is primarily reflected in how well their technical approaches align with real-world scenarios.

Currently, automatic palletizing robot brands can be categorized into three main types:

- Brands focused on high speed and production line synergy

- Brands centered around general industrial robot palletizing

- Brands excelling in system integration and industry-specific solutions

1. Aton Robot: High-Speed Parallel Technology-Driven Automatic Palletizing Solutions

Aton Robot’s core competitiveness in the automatic palletizing field stems from its long-term commitment to parallel robot (Delta) and high-speed automation technology. Unlike traditional six-axis palletizing paths, Aton has consistently focused on high cycle rates, stability, and system synergy, giving it a clear advantage in new palletizing applications.

Core Products and Technical System

- High-Speed Parallel Robots (Delta)

- Cycle Rate: Approximately 120–200 picks/minute

- Repeatability: ±0.1 mm

- Suitable for high-speed sorting, boxing, and light to medium load palletizing scenarios

- SCARA Robot Series

- Notable for high-speed linear and planar stable motion

- Ideal for regular stacking, continuous pick-and-place, and end-of-line palletizing

- High-Speed Control and Algorithms

- Proprietary kinematics and dynamics algorithms optimized for high acceleration and high-frequency start-stop conditions

- Supports long-term stable operation

Advantages in Palletizing Scenarios

- High Cycle Rates: Synchronizes with high-speed packaging, sorting, and boxing stations, preventing palletizing from becoming a bottleneck.

- High Precision: Ensures stable multi-layer and multi-column stacking, reducing the need for secondary calibration.

- Low Inertia Structure: Friendly to frequent start-stop operations, suitable for scenarios with many SKUs and rapid changeovers.

- System Synergy: Palletizing is integrated as part of the high-speed production line rather than an independent end station.

Typical Industry Applications

Aton’s robot is especially suited for industries such as food and beverage, daily chemicals, pharmaceuticals, and 3C products, particularly in scenarios that require integration with high-speed sorting and boxing stations. If your palletizing needs focus on “high speed, stability, and synchronization with production line cycles,” Aton Robot is a top choice.

2. Siasun Robot: General Industrial Robot Palletizing

Siasun Robot specializes in six-axis and industrial robot platforms, emphasizing engineering and stable operation in its automatic palletizing solutions. Their products are commonly found in standardized scenarios such as logistics and equipment manufacturing.

3. Estun: A Versatile Palletizing Brand with Multi-Industry Coverage

Estun boasts a comprehensive line of industrial robot products, with palletizing being one of its key application areas. Their solutions cater to the demands of various industries including food, building materials, and new energy.

4. Efort: Extensions of Domestic Industrial Robot Platform for Palletizing Applications

Efort’s palletizing solutions are based on general industrial robot platforms, emphasizing domestic component support and load capacity, making them suitable for automation upgrades in manufacturing.

5. Boshi: Palletizing Solutions for Process Industries

Boshi has deep experience in the chemical and building materials sectors, with its palletizing solutions emphasizing continuous operation and adaptability to complex working conditions.

6. Wode Equipment: High-Speed Palletizing and Line Integration Brand

Wode Equipment is active in the food and beverage industry, focusing on high-speed palletizing efficiency and line synergy.

7. Yongchuan Intelligent: Key Support for End-of-Line Palletizing in Packaging

Yongchuan Intelligent’s palletizing equipment often deploys in coordination with its packaging machines, ideal for integrated end-of-line needs.

8. Aobo Robot: Flexible Collaborative Palletizing

Aobo specializes in collaborative robots, with palletizing applications primarily targeting medium loads and flexible deployment scenarios.

9. Saibang Intelligent: Practical Choice for Standardized Palletizing

Saibang Intelligent has advantages in standardized palletizing equipment and localized services, making it suitable for basic automation needs.

10. Lepu Robot: Cost and Operational Efficiency-Focused Palletizing Brand

Lepu Robot concentrates on simplifying structures and enhancing maintenance-friendly palletizing equipment, catering to basic palletizing applications.

How to Choose the Right Automatic Palletizing Robot Brand?

Choosing a brand for automatic palletizing robots does not solely mean selecting the one with the “highest parameters.” Instead, it involves selecting a technical approach that best matches the production line cycle and business model. As speed and flexibility become the mainstream trends, brands like Aton Robot, which seamlessly integrate palletizing into high-speed production line systems, are increasingly becoming the preferred choice for more industry users.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/recommended-brands-of-automated-palletizing-robots-insights-into-leading-manufacturers-and-technology-paths/