Key Technologies of the “Three Electric” System in New Energy Vehicles: Battery, Electric Control, and Motor

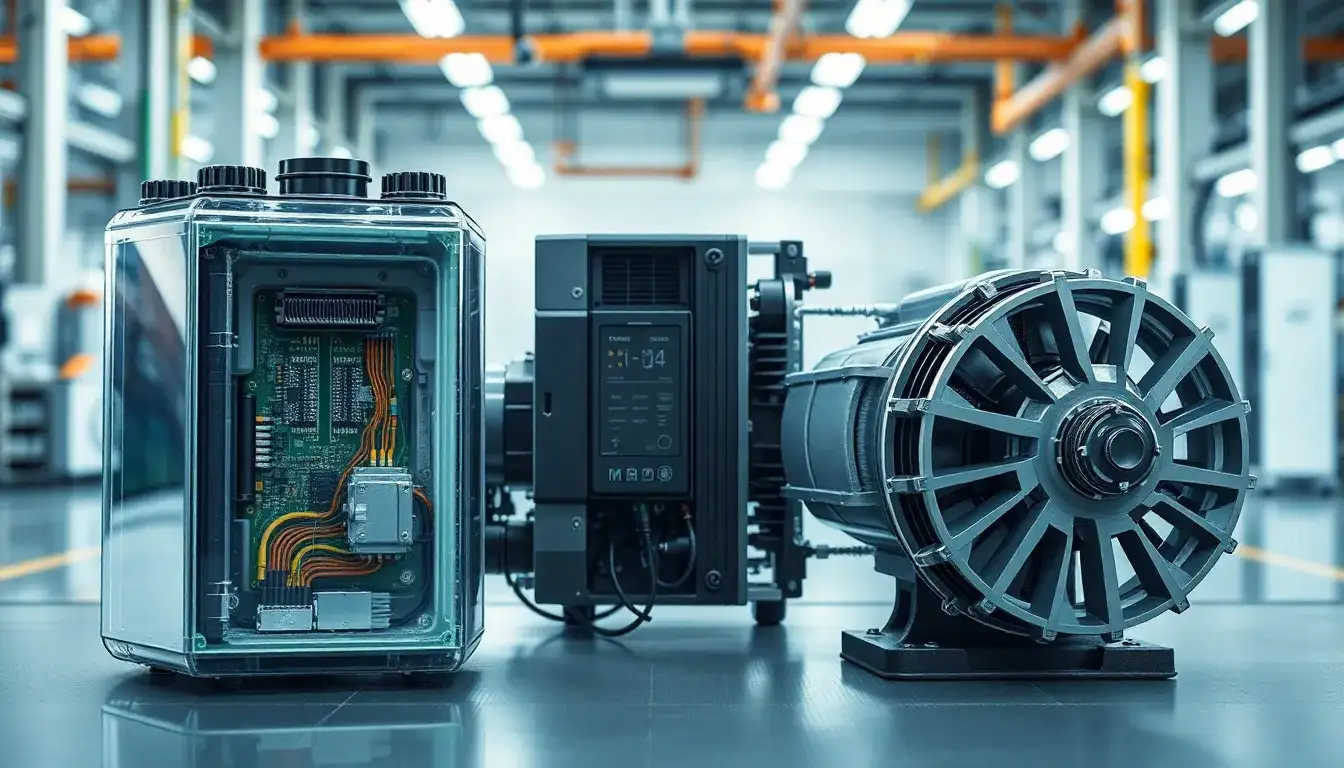

The “Three Electric” system in new energy vehicles, which consists of the battery, motor, and electric control system, is fundamentally different from the traditional components of fuel vehicles, namely the chassis, engine, and transmission. This trio plays a critical role in new energy vehicles, collectively influencing the vehicle’s power performance, efficiency, reliability, and safety. They are indispensable, functioning as the “heart,” “brain,” and “nervous system” of new energy vehicles.

1. Battery: The Heart of New Energy Vehicles

The battery is often referred to as the “heart” of new energy vehicles, as its performance directly determines the vehicle’s range. It accounts for approximately 40% to 60% of the overall vehicle cost. The Battery Management System (BMS) plays a crucial role, acting like an experienced “doctor” that constantly monitors the battery’s status to ensure efficient and safe power delivery to the vehicle.

Core Tasks and Key Technologies

The primary mission of the BMS is to maintain the battery in an optimal state during operation. This includes real-time monitoring of voltage, current, and temperature to prevent potential risks such as over-discharge, overcharge, and overheating. The three core technologies of BMS include:

- SOC (State of Charge) Estimation: Using complex algorithms to accurately estimate the remaining battery capacity, which is crucial for smooth vehicle operation.

- Balancing Control: Ensuring consistency among individual battery cells, enhancing the stability of the battery pack and increasing output power.

- Thermal Management: Keeping the battery within an appropriate temperature range to improve performance and extend lifespan.

Battery Working Principle

Batteries convert chemical energy into electrical energy through chemical reactions. During discharge, internal chemical substances react to generate current and energy. Parameters such as voltage, current, and temperature change with the operating state, and monitoring these parameters in real-time is essential for safe and efficient battery operation.

2. Main Technology Routes

The core of the power battery is the cell, which consists of positive and negative electrodes, separators, and electrolytes. In the field of new energy vehicles, there is a diversity of battery technology routes. Currently, the mainstream technologies include CATL’s ternary lithium batteries and BYD’s lithium iron phosphate batteries. Ternary lithium batteries are favored in northern markets for their excellent low-temperature performance, though they face challenges regarding production costs and high-temperature safety. Conversely, lithium iron phosphate batteries are well-regarded for their superior safety and cycle life, although they exhibit rapid capacity degradation in low-temperature environments.

Comparison of Ternary Lithium and Lithium Iron Phosphate Batteries

Both battery technologies have unique advantages. The ternary lithium battery is preferred in colder climates due to its low-temperature performance, but improvements are needed in terms of production costs and safety at high temperatures. The lithium iron phosphate battery, while stable and safe, loses capacity quickly in low temperatures.

3. Outlook for New Battery Technologies

Solid-State Batteries: This cutting-edge technology utilizes sodium or lithium as battery materials and features solid-state electrolytes. This innovative design significantly enhances battery safety, reduces short-circuit risks, and achieves energy densities that are 3 to 5 times greater than conventional lithium batteries. It also boasts an impressive cycle life, maintaining less than 5% degradation even after 500,000 kilometers of use, representing the ultimate ideal in lithium battery technology. International companies have already begun mass production of this technology, showcasing its potential to replace traditional lithium batteries.

Graphene Batteries: Known for their ultra-fast charging capability, graphene batteries can achieve a range of 1000 kilometers with just a 10-minute charge. The stability of their carbon atomic structure ensures high safety. While the current cost of graphene batteries is relatively high, ongoing advancements and cost reductions could lead to widespread adoption soon.

4. Latest Research Directions

State of Health (SOH) Monitoring Technology: This technology enables real-time tracking and assessment of the battery’s current state, predicting its remaining lifespan and providing valuable data for maintenance and replacement.

Data-Driven BMS Optimization Strategies: Utilizing big data analysis and artificial intelligence, BMS systems can refine the control of battery charge and discharge processes, enhancing battery efficiency and overall lifespan.

Vehicle Control Unit (VCU)

The Vehicle Control Unit (VCU) is the core component of the vehicle’s drive coordination control system, responsible for coordinating the overall vehicle state and meeting the driver’s demands, often regarded as the “brain” of the vehicle.

Core Functions

The VCU’s core functions include:

- Real-time monitoring and coordination of the vehicle’s state by collecting data from various sensors, ensuring optimal performance across systems.

- Precise response to driver inputs, such as acceleration, deceleration, and steering, allowing for a smooth and stable driving experience.

- Energy management, intelligently adjusting charging and discharging strategies based on vehicle status and driving needs to optimize energy efficiency.

VCU Structure and Key Technologies

The VCU comprises several components, including a shell, hardware circuits, low-level software, and application-level software. The hardware circuit utilizes standardized core modules, including a 32-bit main processor, power supply, memory, and CAN interfaces, along with dedicated circuit designs for sensor data acquisition to ensure good portability and scalability. As automotive-grade processor technology advances, the VCU has increasingly adopted 32-bit processor chips, becoming an industry standard.

On the software side, the low-level software adheres to the AUTOSAR standard, supporting diverse control systems while utilizing modular design to enhance software quality and shorten development cycles. Key technologies focus on driver torque analysis, gear shifting strategies, seamless mode switching, torque distribution, and fault diagnosis strategies, significantly impacting vehicle performance, fuel efficiency, and overall reliability.

5. Latest Research Directions for VCU

In the context of electrification and intelligence, the VCU has evolved into the core domain controller for vehicles, leading the trend of multi-domain integration to optimize overall vehicle performance. It integrates key systems such as power, thermal management, and on-board diagnostics while achieving deep integration of body and chassis control, as well as intelligent driving functionalities. This cross-domain integration provides a solid foundation for energy management and optimization.

Motor Controller

The motor controller serves as the core component of the vehicle’s power system, acting as the “nervous system” connecting the motor and battery. Its performance directly affects overall vehicle capabilities. It not only ensures safe and precise vehicle control but also guarantees efficient and stable operation of the battery and motor, providing a safe and comfortable driving experience.

Core Functions of the Motor Controller

The motor controller consists of low and high voltage sections, encompassing input/output interface circuits, control boards, processors, memory, and sensors. The IGBT module, as a core component, efficiently converts DC power to AC power, enabling smooth motor operation.

Working Principle of the Motor Controller

The working principle of the motor controller varies based on the type of current and motor driving method, primarily categorized into DC motor controllers and AC motor controllers. In the case of stepper motor driving, it can be further divided into unipolar and bipolar driving circuits.

Key Technical Directions

- Efficient Power Conversion Technology: Aiming to achieve smooth and efficient conversion of electrical energy from the battery to the motor, providing a stable power source for the vehicle.

- Precise Control Algorithms: Utilizing advanced algorithms to ensure meticulous control of the motor, thereby enhancing vehicle power performance and driving stability.

- Advanced Thermal Management Technologies: Effectively managing heat produced by the motor controller during operation to ensure long-term stability.

Recent Research Directions

Multi-in-One Integration: Focused on advancing multi-in-one integration technology to reduce the size of the drive system and streamline wiring harness connections, enhancing overall vehicle integration and reliability.

Dual Motor Control Function: Exploring the implementation of dual motor control capabilities for both the drive motor and generator to further optimize vehicle power performance and improve energy efficiency.

Application of High-Performance Materials: Researching the use of new high-performance materials in core components like the IGBT module to enhance conversion efficiency and ensure stable operation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/key-technologies-of-the-three-electric-system-in-new-energy-vehicles-battery-electric-control-and-motor/