In the rapidly evolving energy storage industry, economic viability serves as a competitive factor, while safety is the essential key to success. The latter imposes strict, zero-tolerance constraints that determine the ceiling for technological advancements and the baseline for commercial implementation. The industry has transitioned from early, indiscriminate capacity stacking to a refined operational model driven by both capital and policy. As a result, the energy storage sector finds itself at a critical juncture: every enhancement in safety redundancy comes at a geometric cost to economic efficiency.

On April 10, at the 13th International Energy Storage Summit and Exhibition, Zhejiang Gaotai Haoneng Technology Co., Ltd. (referred to as “Gaotai Haoneng”), a pioneer in energy storage innovation, unveiled a range of new products and technologies. These include an immersion cooling temperature control system based on their proprietary 4S+C stack development, an integrated solar-storage machine, an immersion liquid cooling series for industrial and large-scale storage solutions, an active balancing BMS, and a PCS energy storage inverter. Amid the industry’s dynamic shifts, Gaotai Haoneng is capturing attention for its exceptional technical expertise and innovative spirit.

During the exhibition, the North Star Energy Storage Network engaged in a deep discussion with Gaotai Haoneng’s Chairman, Zhang Weifeng, about the new opportunities and challenges within the energy storage sector, as well as the company’s strategic positioning and technological innovations.

Innovative Integration to Address Thermal Management Challenges

The operation of energy storage stations requires a stable temperature. Extreme temperatures, whether too high or too low, can adversely affect the efficiency and lifespan of the storage systems. Particularly, excessively high temperatures can lead to battery cell fires or explosions, posing significant safety threats. “From the perspective of battery technology, addressing safety issues can follow two main paths: one is the development of all-solid-state batteries, which may not be commercially viable for at least five years due to cost and scalability issues. The other is to address the shortcomings of existing lithium iron phosphate battery technology. Hence, we have developed the 4S+C stack, incorporating BMS/EMS/PCS/TMS+Cloud, as a strategy to meet the increasing demands of energy storage applications,” Zhang Weifeng explained.

Currently, the industry has proposed various solutions for the thermal management of energy storage systems. The two primary approaches available in the market are liquid cooling and air cooling, each with its pros and cons. Liquid cooling offers higher specific heat capacity and thermal conductivity than air, resulting in faster cooling speeds that significantly reduce peak temperatures and enhance temperature consistency across battery modules. This method has gained broad acceptance due to its ability to improve both the safety and economic efficiency of energy storage systems, ensuring user experience and returns.

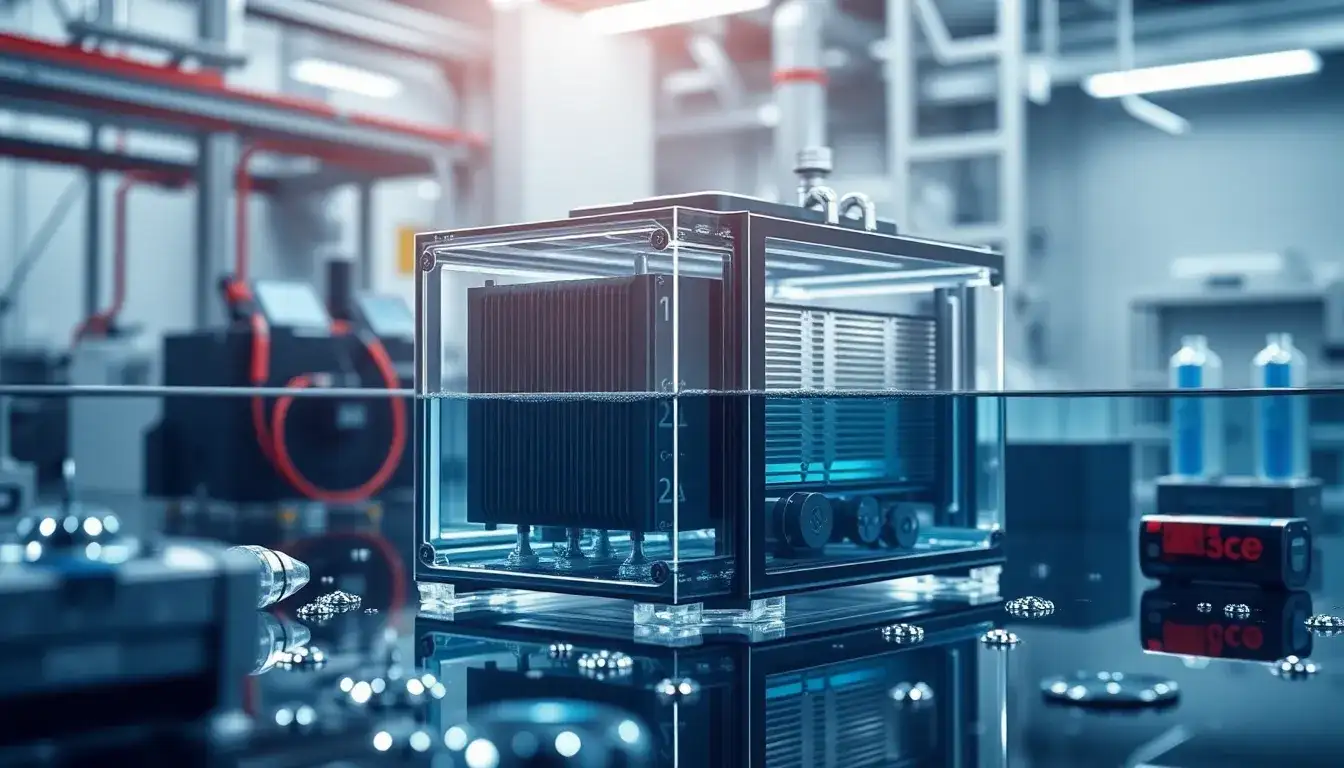

However, traditional liquid cooling methods face challenges such as uneven heat dissipation and condensation issues, which can lead to electrical leakage risks and corrosion of metal components over time, affecting system stability. In contrast, Gaotai Haoneng’s immersion liquid cooling system fully submerges the energy storage cells in coolant, isolating them from air and moisture, thereby completely eliminating the risk of battery combustion or explosion. This system effectively regulates operational temperatures, facilitating rapid, thorough, and uniform cooling, ensuring long-term stable operation of the batteries.

Zhang Weifeng believes that the immersion liquid cooling system is currently one of the safest thermal management methods available for energy storage. Utilizing the unique characteristics of this system, Gaotai Haoneng has developed a series of industrial and large-scale storage solutions that integrate cooling, heating, intelligent control, and fire safety. This approach combines physical isolation with intelligent monitoring to ensure safe and efficient operation. The immersion temperature control system is coupled with the BMS management system, allowing for precise temperature control and intelligent adjustments that enhance temperature consistency, keeping the temperature difference among cells below 2°C. This innovation extends battery capacity and cycle life while reducing operational costs.

Moreover, the system accommodates higher charge and discharge rates (greater than 1C). Zhang Weifeng noted that this system utilizes a semi-closed design, simplifying the Pack design requirements and significantly lowering production costs, bringing it in line with the price of traditional liquid cooling plate products. The design improves liquid flow with top-entry, enhancing convective heat transfer while reducing liquid usage by 80%, resulting in cost advantages over similar products. Furthermore, it eliminates the need for separate cooling and fire safety systems, greatly increasing integration and reducing equipment size, making it suitable for high-safety applications. It can also be deployed in extreme environments such as sub-zero temperatures, high altitudes, and arid conditions.

In addition, Zhang Weifeng revealed that the production process for the cooling medium is highly mature, allowing for low mass production costs that meet market demands. This series of products is expected to complete third-party certification this month and enter mass production by June.

Beyond product technology, Gaotai Haoneng has also made upgrades at the system level. Through ongoing research and development of their “4S+C stack” closed-loop system, in collaboration with Tsinghua University, the company has integrated artificial intelligence into existing product lines. By employing LSTM/Transformer models to analyze historical data, they can predict thermal runaway risks and provide early warnings up to 30 minutes in advance. “The integration of AI technology is a key focus for our thermal runaway warning system,” Zhang Weifeng emphasized. This system enhances safety and reliability by enabling early detection of temperature anomalies and gas leaks, issuing alerts 5 to 30 minutes in advance, activating liquid cooling or aerosol fire suppression to slow the spread of heat by over 50%, and isolating faulty modules to prevent chain reactions, thus reducing losses by more than 80%.

Building a Comprehensive Safety Network for Energy Storage

Safety and economic efficiency are two critical topics in the realm of industrial and commercial energy storage. The focus is shifting from energy management to energy trading, presenting new challenges for energy storage companies. The era of energy storage 1.0, which relied solely on fixed peak-valley price differences, has ended; today, with real-time fluctuations in electricity prices, energy storage systems must adapt to new requirements that go beyond basic charging and discharging capabilities. “If we can break down barriers or achieve integrated optimization, energy storage products can generate more revenue streams,” Zhang Weifeng noted. However, he acknowledged that many companies currently lack the necessary integration capabilities. Gaotai Haoneng is positioned to help clients quickly adjust to future application changes, which is the fundamental reason for proposing the 4S+C overall solution.

In addition to the immersion temperature control system and industrial/large-scale storage solutions, Gaotai Haoneng has implemented several technological innovations in BMS and other areas. Notably, they have integrated TMS into their offerings, creating a unique solution that combines heat management and fire safety. This comprehensive system significantly addresses safety and temperature control concerns. Since its establishment in 2011, Gaotai Haoneng has been at the forefront of energy storage technology and continuously innovates to meet industry demands.

This year, Gaotai Haoneng launched its second-generation active balancing BMS, which has undergone extensive optimizations compared to the first generation, particularly in localization, bidirectional balancing, balancing current, and efficiency. The new product achieves a balancing efficiency of over 80%, reducing energy loss and improving the overall energy utilization of battery packs. With advanced active balancing algorithms and hardware designs, the new product swiftly identifies and balances imbalances within battery packs, significantly shortening balancing times and enhancing system responsiveness. The design features ultra-wide dimensions that meet international certification requirements and facilitate export.

Zhang Weifeng stated that the new product supports balancing currents of 1 to 3 A, enabling faster and more uniform energy distribution within battery packs, thus further extending battery lifespan. The integration of active and passive designs streamlines the system, reducing complexity while improving balancing effectiveness and overall reliability. “Safety is the cornerstone of energy storage operations; only by ensuring safe system operation can we achieve long-term stable profitability,” Zhang Weifeng emphasized. Gaotai Haoneng is strategically adjusting to new industry opportunities and challenges through its fully self-developed technology and intelligent management systems.

The introduction of the “4S+C stack” model allows for a complete closed loop of core energy storage processes. Compared to the commonly adopted “multi-supplier assembly” models in the industry, this approach offers significant advantages. Consistent data sources among multiple self-developed products eliminate redundant data and operational interference, greatly reducing product failure rates. By optimizing system design and enhancing efficiency, operational costs are lowered, improving economic benefits.

Zhang Weifeng also highlighted that Gaotai Haoneng’s next-generation active balancing BMS can withstand voltages up to 6000V DC, ensuring safety and stability under high-voltage conditions, meeting both domestic and international certification standards, and enabling bidirectional charging and discharging between 24V and the battery cells.

This year, with the rising trend of “artificial intelligence +”, technologies like DeepSeek are experiencing rapid growth, reshaping ecosystems across various industries. Gaotai Haoneng is integrating DeepSeek technology to enhance its energy storage management systems. Zhang Weifeng admitted that successfully integrating the DeepSeek AI model significantly boosts the efficiency of staff and maintenance personnel, playing a vital role in the diagnostic process for energy storage equipment.

Gaotai Haoneng has successfully utilized these trained expert models to resolve issues traditionally only solvable by experienced developers, greatly lowering the barriers to problem diagnosis. The company’s BMS and EMS products are deeply integrated into a big data platform, leveraging AI algorithms to provide crucial functionalities such as user load forecasting models, photovoltaic generation forecasting models, and battery life assessment models.

Innovation capacity and technological reserves remain core competitive advantages for enterprises facing fierce market competition. As the industry shifts focus from “price” to “value,” meeting goals of “quality improvement, cost reduction, and efficiency enhancement” requires persistent breakthroughs in innovation to discover new opportunities.

Recently, a series of new policies have illuminated the path forward for the industry. Gaotai Haoneng has proactively positioned itself in AI and big data applications, establishing a comprehensive ecological service model through technological innovation and business expansion, transitioning from a pure equipment provider to an integrated solution provider. Zhang Weifeng stated, “In the future, Gaotai Haoneng will continue to monitor industry trends, actively respond to market changes, and achieve sustainable development through technological innovation and strategic adjustments. We will also increase our investment in technology research and market expansion to provide customers with more comprehensive, efficient, and reliable digital smart energy system solutions.”

Since its establishment in 2011, Gaotai Haoneng has been a prominent player in the fields of new energy vehicles and energy storage BMS. Utilizing fully self-developed technology and intelligent management systems, it has significantly enhanced the safety and reliability of energy storage systems while offering users more efficient and economical energy storage solutions. Through continuous technological innovation and market expansion, Gaotai Haoneng is driving the high-quality development of the energy storage industry within the context of a new power system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/innovative-immersion-cooling-system-by-gaotai-haoneng-tackles-energy-storage-safety-challenges/