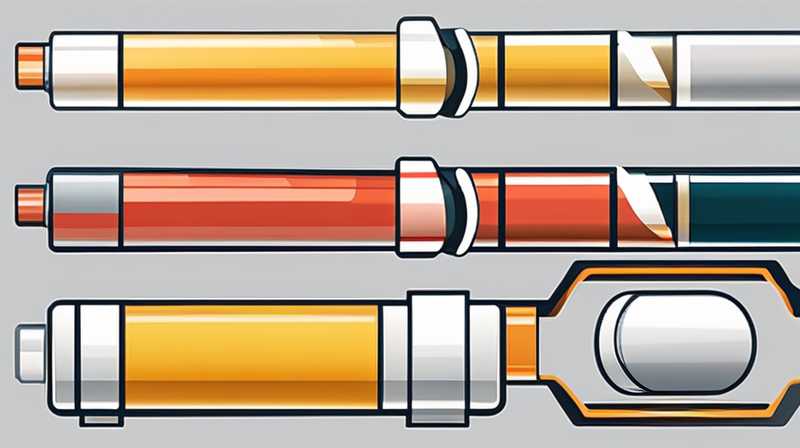

To effectively wrap solar tube tape around your solar heating system, follow several key steps. 1. Preparation is essential, ensuring the surface is clean and dry, which allows for better adhesion. 2. Correct alignment plays a crucial role; begin wrapping from the bottom and move upwards. 3. Tension consistency is necessary throughout the application, preventing wrinkles or bubbles. 4. Use appropriate cutting tools for clean edges, ensuring the tape adheres properly without fraying. 5. Final inspection is critical to verify that the tape is securely applied and functioning optimally. This methodical approach ensures durability and efficiency in your solar heating application.

1. PREPARATION

Wrapping solar tube tape starts with meticulous preparation. The surface onto which the tape will adhere must be free of dust, dirt, or moisture. This step is critical; any contaminants can compromise the tape’s adhesive properties, leading to premature failure. Using a damp cloth, clean the area thoroughly and allow it to dry completely before proceeding.

Having the right tools and materials at hand can also facilitate a smoother wrapping process. You will need high-quality solar tube tape, scissors or a utility knife for cutting, and a ruler or measuring tape for precision. By ensuring that everything is within reach, distractions can be minimized, allowing for a more focused and efficient wrapping experience.

2. ALIGNMENT

Correct alignment is paramount when applying solar tube tape. Starting at the bottom of the tube and gradually working your way upwards creates a uniform appearance and prevents the tape from peeling off over time. Align the tape with the tube’s edge to maintain a straight application.

As you begin to wrap the tape, keep it snug but not overly tight. If the tape is pulled too tightly, it may lose its elasticity or create bulges. Maintaining a moderate tension allows the tape to conform to the curve of the tube while ensuring an even layer of insulation is in place. This careful technique significantly contributes to the longevity and effectiveness of the solar tube installation.

3. WRAPPING TECHNIQUE

The actual wrapping method plays a significant role in the success of the tape application. Begin by affixing the tape to the bottom of the tube, securely pressing it down to initiate a firm bond. As you wrap, ensure that each subsequent layer overlaps the previous one by about half. This overlap technique enhances the seal and improves insulation, which is crucial for solar applications.

Care should be taken to ensure smooth application during this process. Any wrinkles or bubbles can lead to reduced efficiency and aesthetic issues. Should you encounter any imperfections, address them immediately by gently removing the tape from the affected area and reapplying it. This attention to detail ultimately determines the effectiveness of the insulation.

4. CUTTING AND FINISHING

When you reach the top of the solar tube, it is time to cut the tape. Using sharp scissors or a utility knife, make a clean cut to avoid frayed edges, which could compromise the integrity of the installation. Utilizing a straight edge or a ruler can aid in producing a clean line and ensure precision.

After cutting, it’s crucial to press down the edges firmly to guarantee a complete seal. Each end of the tape should be checked to ensure there are no gaps or lifting sections, as these can lead to heat loss and diminished performance. Taking the time to finish this step carefully can dramatically impact the efficiency of the system.

5. FINAL INSPECTION

Upon completing the application, conducting a thorough inspection is essential. Examine the entire wrapped area for any irregularities such as bubbles, wrinkles, or gaps. Addressing these issues at this stage prevents problems in the future, ensuring that the insulation remains effective throughout its lifespan.

Testing the tube’s effectiveness may also be beneficial. This can be achieved by monitoring the temperature around the tube or observing the performance of the solar heating system after the installation. Should any issues arise, they can typically be resolved by adjusting or rewrapping the tape as needed. Commitment to excellence during this final review can enhance both performance and longevity.

FAQs

WHAT TYPE OF TAPE IS BEST FOR SOLAR TUBING?

Choosing the right tape for solar tubing applications is imperative for ensuring both durability and efficiency. Solar tube tape is specifically called reflective insulation tape. It is designed to handle high temperatures and resist environmental factors like moisture and UV rays. The most common materials used are aluminum foil combined with a high-performance adhesive backing. This type of tape reflects heat rather than absorbs it, optimizing the efficiency of the solar tube system. When selecting the tape, look for options that have been tested and certified for solar applications, ensuring that they meet industry standards. Thickness can also vary, with thicker options typically providing better insulation; however, this must be balanced with flexibility for application ease. By making an informed choice, you can significantly improve the effectiveness and longevity of your solar heating system.

HOW LONG DOES SOLAR TUBE TAPE LAST?

The longevity of solar tube tape can vary based on several factors, including the quality of the tape, the application method, and the environmental conditions it faces. Generally, high-quality solar tube tape is expected to last anywhere from five to ten years. Factors that contribute to this lifespan include exposure to sunlight, variations in temperature, humidity levels, and the presence of contaminants. Proper application techniques also play a crucial role; if the tape is applied correctly, adhering fully to the surface, it is more likely to maintain its effectiveness over time. Regular inspections can help identify any potential issues early, allowing for prompt repairs or replacements. Investing in high-quality materials and following best practices for installation can significantly extend the life of solar tubing.

CAN YOU REMOVE AND REAPPLY SOLAR TUBE TAPE?

While it is technically feasible to remove and reapply solar tube tape, doing so requires careful attention. The process of removal can lead to damage to the insulation or the surface of the solar tube itself. If the tape is pulled off too aggressively, it may leave behind adhesive residue or even peel off the underlying surface. In cases where reapplication is necessary, the best approach is to use a heat gun to gently warm the tape, making it easier to peel away. Once removed, one must ensure that the surface is thoroughly cleaned and free of any adhesive remnants before applying new tape. This not only maintains the aesthetics of the installation but also ensures proper adhesion of the new tape. Being methodical and careful during this process can help in achieving a satisfactory outcome.

In Summary

Applying solar tube tape requires precision and care to ensure optimal performance. The initial steps involve thorough preparation, focusing on cleanliness and readiness for application. Alignment is also vital, helping to maintain uniformity while wrapping. A meticulous wrapping technique minimizes imperfections and enhances insulation effectiveness. After cutting and finishing, conducting a thorough inspection can lead to a successful outcome. Careful attention to these steps guarantees a long-lasting and efficient solar heating system. By adhering to best practices during each phase of the application, it is possible to maximize energy savings and bolster the performance of solar installations. Engaging with high-quality materials, utilizing expert techniques, and regularly maintaining the system can lead to enhanced performance and sustainability, ultimately reducing energy costs and increasing overall system efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-wrap-the-solar-tube-tape/