1. Wrapping frozen solar tubes effectively ensures better insulation and prevents damage, essential for maintaining their operational efficiency. 2. Proper materials are key; using insulating materials like foam or specialized wraps helps in reducing heat loss. 3. Timely wrapping before freezing temperatures sets up a preventive measure that saves on maintenance costs. 4. Following the correct procedure for wrapping is crucial to avoid trapped moisture, which could lead to further complications. 5. Regular checks during the winter season can help address issues early, ensuring long-term sustainability.

UNDERSTANDING FROZEN SOLAR TUBES AND THEIR CHALLENGES

Solar tubes are an integral component of modern solar heating systems. These cylindrical structures harness sunlight, converting it into usable thermal energy. However, in cold weather conditions, these tubes face the adverse impact of freezing temperatures. Understanding the innate challenges posed by cold weather is crucial for ensuring longevity and optimal performance of these systems.

Frozen solar tubes can lead to inefficiencies and physical damage, necessitating a proactive approach to their protection. When temperatures drop, any water within the tubes can freeze, leading to expansion that might compromise their structural integrity. Consequently, owners should recognize that the risk of damage escalates without proper preventive measures in place. This understanding forms the basis of ensuring solar installations endure even in less favorable weather conditions.

While solar tubes are designed with durability in mind, weather-related strains may still occur without intervention. By exploring the methods for effectively safeguarding solar tubes from freezing, property owners can mitigate damages, maintain operational efficiency, and protect their investment throughout winter.

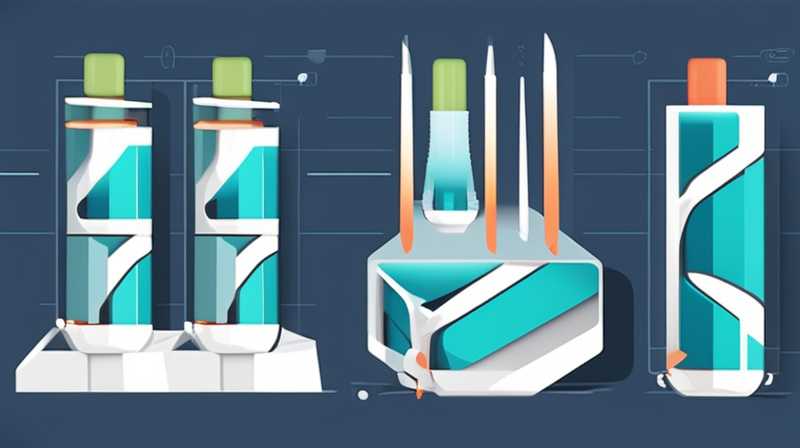

1. MATERIAL SELECTION FOR INSULATION

Choosing the right materials for insulating frozen solar tubes is paramount. The insulation effectiveness directly correlates with the ability to withstand severe climate conditions. Various options exist, such as foam insulation, reflective insulation wraps, and fiberglass. Each material offers unique advantages, which must be carefully evaluated.

Foam insulation serves as an optimal choice due to its excellent thermal resistance properties. This material, often available in pre-formed sleeves, can be cut to size, making it easy to apply directly to solar tubes. Construction-grade foam is specifically designed to withstand outdoor elements, maintaining its structural integrity through diverse weather conditions. The properties of foam enable it to trap air—an excellent insulator—while simultaneously resisting moisture absorption.

In contrast, reflective insulation wraps offer a dual function. Initially developed for radiant heat barriers, the reflective layer minimizes heat loss by reflecting thermal energy back towards the tubes. This type of insulation is particularly valuable in maintaining the temperature of the tubes, especially in environments subjected to sharp temperature variations. By utilizing both foam and reflective materials in conjunction, one can achieve optimal insulation tailored to specific climatic scenarios.

2. PREPARING SOLAR TUBES FOR WINTER

Before applying wrapping materials, thorough preparation of the solar tubes is essential. This process involves cleaning the tubing surfaces to remove any debris, algae, or existing moisture. Such contaminants can interfere with the integrity of insulation materials and compromise their efficacy.

Starting with a comprehensive clean ensures that insulating materials adhere properly to the tubes. Utilizing a soft brush or cloth with mild cleaning agents allows for effective cleansing without damaging the tubes’ surfaces. Following this, it is critical to allow ample time for drying, as excessive moisture trapped beneath wraps may exacerbate freezing issues rather than alleviate them.

Furthermore, inspecting the tubes for any already existing damage becomes vital. Minor cracks or signs of wear demand immediate attention before applying protective wraps. With the components cleaned and assessed, the groundwork is laid for a successful insulation project that will ultimately preserve efficiency and longevity. This preparatory phase ideally positions users for effective wrapping of the solar tubes.

3. STEP-BY-STEP WRAPPING PROCESS

Once the necessary materials have been selected and the tubes have been properly prepared, the wrapping process can commence. The steps in this procedure are critical to ensure that the insulation is both efficient and tightly fitted. Each element should be completed methodically to guarantee optimal results.

Begin by measuring the solar tubes to determine the quantity of insulation material required. It’s essential to cut the foam or reflective wrap to the appropriate length to ensure no gaps remain that could allow heat to escape. Position the insulation on the solar tubes carefully, ensuring that the wraps overlap slightly as one moves from the top down towards the bottom. Secure the wraps using heavy-duty tape or ties, guaranteeing that they remain in place throughout winter.

Importantly, attention should be paid to any gaps or loose areas during the wrapping process. These inconsistencies can lead to inefficiencies, as cold air may penetrate through even the smallest openings. Thus, snug and secure wrapping becomes paramount for maximizing the benefits of insulation.

After completion of the wrapping, check the entire setup for stability and ensure all materials are tightly secure. Inspecting the final result guarantees that no vulnerabilities remain, reinforcing the design to resist freezing challenges effectively.

4. REGULAR MAINTENANCE AND INSPECTION

Maintaining the integrity of wrapped solar tubes extends beyond the initial insulation application. Property owners should establish a routine inspection schedule, particularly during and after winter storms. Regular checks allow for the identification of any wear, loose materials, or potential damages that may have occurred due to extreme weather conditions.

This proactive approach must also encompass an evaluation of overall performance; measuring the efficiency of heat absorption is crucial. If performance drops significantly following a freeze or thaw cycle, owners might need to reassess their insulation strategies. In such situations, addressing leaks and replacing worn-out materials becomes imperative to restoring optimal functionality.

Engaging with professional maintenance services to conduct comprehensive annual checks can provide further assurance of the installations’ integrity. Expert assessments can identify underlying issues that may not be readily visible during casual inspections, safeguarding the overall health of the solar heating system.

5. COMPONENTS AFFECTING INSULATION EFFICACY

Various factors beyond just wrapping materials can significantly affect the thermal insulation efficacy of solar tubes. Environmental elements, including wind velocity, moisture levels, and sunlight exposure, can pose challenges that need addressing in insulation strategies. Property owners should be aware that high winds may drive cold air into any openings or gaps in insulation, thus effectively countering heating efforts.

Moisture levels in the environment can also play a considerable role in insulation effectiveness. Excess moisture trapped beneath wraps can lead to freeze-thaw cycles that compromise both materials and operational efficiency. By utilizing drying agents or moisture barriers, owners can further protect insulation layers.

Moreover, the positioning of solar tubes influences cooling and heating cycles. If tubes are oriented in areas with high sun exposure, they can absorb more heat; however, when wrapped improperly, heat might escape quicker as well. Understanding these multifaceted determinants aids owners in adopting the most effective insulation and maintenance strategies.

FAQs

WHAT MATERIALS ARE BEST FOR WRAPPING FROZEN SOLAR TUBES?

When choosing materials for wrapping solar tubes, options such as foam insulation, reflective wraps, and fiberglass can be effective. Foam insulation offers excellent thermal resistance and is easy to apply and cut to size. The pre-formed sleeve format allows for a snug fit that traps heat efficiently. Reflective insulation is valuable in redirecting heat back into the tubes, minimizing thermal escape. A combination of these materials may offer enhanced protection, particularly in extreme climates.

HOW OFTEN SHOULD I INSPECT MY WRAPPED SOLAR TUBES?

Regular inspections of your wrapped solar tubes should be conducted. During winter months, it’s advisable to check every couple of weeks, especially after significant temperature changes or storms. In these assessments, pay attention to the integrity of the insulation; are there any tears or loosening? Furthermore, monitoring the performance of your solar heating system can indicate whether additional steps may be necessary. Scheduling an annual professional inspection can also add an additional layer of security to ensure long-term efficiency.

WHAT ARE THE SIGNS THAT INSULATION IS NOT WORKING EFFECTIVELY?

Indicators that the insulation of solar tubes is not functioning optimally can include significant drops in system performance and physical defects in the insulation materials. If you notice that your heating system is working harder than usual or heating output is lower than expected, it could signal insulation failure. Additionally, visual signs such as moisture accumulation, frost buildup around the insulation, or peeling can illustrate problems. Addressing these issues promptly can protect your investment and enhance operational efficiency.

As cold weather sets in, protecting solar tubes through effective wrapping becomes necessary to mitigate potential damage and ensure systems continue functioning efficiently. Choosing the right materials, preparing the tubes adequately, executing a precise wrapping process, and adhering to a routine inspection schedule are all pivotal actions in safeguarding these systems against the harsh winter elements. By addressing not only the tubes but the myriad of external factors influencing efficiency, property owners are equipped to maximize energy harnessing capabilities sustainably. Incorporating a holistic approach to maintenance and protection extends the life of solar heating systems, allowing for continued benefits for many seasons to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-wrap-frozen-solar-tubes/