1. To wire the tubes of homemade solar panels, begin with gathering necessary components, ensuring proper insulation and safety measures, and carefully following wiring patterns, while double-checking connections thoroughly. 2. Select appropriate tubing materials and solar cells to maximize efficiency, ensuring compatibility and optimal performance. 3. Organize all tools and structures in a well-lit workspace, facilitating a systematic approach to installation and reducing the likelihood of errors. 4. Finally, conduct tests post-installation to ensure all connections are secure and functioning properly, and troubleshoot any issues that arise during the testing process.

UNDERSTANDING SOLAR PANEL COMPONENTS

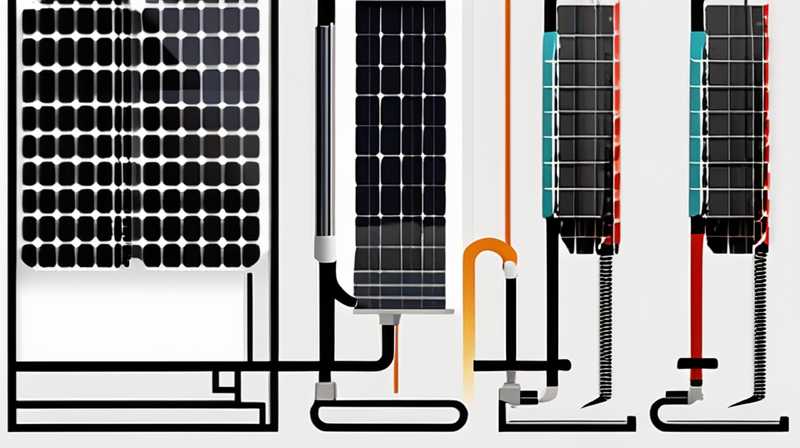

Wiring the tubes of homemade solar panels begins with an understanding of the core components involved in the process. The primary elements include solar cells, which convert sunlight into direct current (DC) electricity, and tubes that house these cells. The quality of materials and the arrangement of the solar cells play a pivotal role in the system’s overall performance and efficiency.

Selecting high-quality solar cells is essential. Options vary between monocrystalline and polycrystalline varieties, each with different efficiency ratings. Monocrystalline cells are known for superior efficiency and longevity, while polycrystalline cells offer a more cost-effective option. Therefore, considering the intended application for the solar panel will guide the optimal choice. Proper attention to detail in sourcing the right solar cells ensures that the solar panels perform at their highest potential.

PREPARING YOUR WORKSPACE

Setting up your workspace is crucial for a successful solar panel wiring project. A clean, well-organized area provides clarity and minimizes the risk of errors. Ensure adequate lighting and ventilation, especially when working with adhesives and tools associated with this project. By doing so, it will become easier to focus on the specific wiring tasks required.

Start by gathering all necessary tools and components like connectors, wires, soldering iron, and insulation tape. Having all components at hand not only streamlines the process but also helps in maintaining an orderly workflow. Proper management of tools ensures all materials are easily accessible during different stages of wiring.

UNDERSTANDING WIRING SCHEMATICS

A clear grasp of wiring schematics for solar panels is necessary. Wiring configurations, such as series and parallel setups, greatly influence the output voltage and current. In a series connection, the voltage increases while the current remains constant, perfect for applications requiring higher voltage. Conversely, a parallel connection maintains the voltage while increasing the current, which is beneficial when increasing the total output of the solar panel array.

To visualize, imagine the series setup as water flowing through a single pipe—adding more pumps increases the pressure (voltage). In contrast, a parallel setup can be envisioned as multiple pipes connected to a single water source, increasing the volume flow of water (current). Understanding these configurations aids in designing a system that meets specific energy needs.

WIRING THE CELLS TO TUBES

The actual wiring of solar cells to the tubes is the next profound phase in this project. Start by securely placing the solar cells within the tubes, ensuring that all cells are oriented in the same direction for maximum exposure to sunlight. It is crucial to connect the positive terminal of one cell to the negative terminal of the next in a series wiring system. This ensures that the voltage is additive across the cells.

When wiring each tube, pay particular attention to soldering techniques. Solder should bond the connections securely without creating any short circuits. Quality solder and tools are important to achieve reliable joints. Furthermore, to increase durability, consider insulating each connection adequately with heat shrink tubing or electrical tape.

ENSURING PROPER INSULATION AND PROTECTION

Protection from environmental elements is essential for the longevity and reliability of homemade solar panels. Humidity, UV exposure, and temperature fluctuations can lead to performance degradation over time. To combat this, thorough insulation is required for each electrical connection, shielding it from moisture and ensuring a secure environment conducive to long-term performance.

Using a clear encapsulant can provide additional protection. Encapsulating the entire assembly in transparent material safeguards the cells and wiring from dirt, oxidation, and physical damage. This step not only protects the components but also enhances the aesthetic appeal of the solar panels.

FINAL TESTING AND ADJUSTMENTS

Once the wiring process is complete, performing tests on the system is crucial. Multimeters can measure voltage outputs to ascertain the effectiveness of the connections made. Take measurements under direct sunlight to ensure accuracy and ideal performance.

If any outputs are below expectations, inspect all connections for potential issues. A systematic approach to troubleshooting—checking each connection, assessing the integrity of the soldered joints, and ensuring adequate insulation—is vital to resolve any problems that may arise. Making necessary adjustments and re-testing will ensure the reliability of the solar panel system.

COMMON QUESTIONS ABOUT SOLAR PANEL WIRING

WHAT TYPES OF WIRING CONFIGURATIONS CAN BE USED FOR SOLAR PANELS?

Solar panels can be connected in series, parallel, or a combination of both configurations. When connecting in series, the positive terminal of one cell is connected to the negative terminal of the next, leading to an increase in voltage while keeping current consistent. This can be particularly advantageous for systems requiring higher voltage output. In contrast, parallel connections involve connecting all positive terminals together and all negative terminals together, thereby increasing total current while keeping voltage constant. Understanding which configuration suits the intended energy requirements is paramount for homeowners or hobbyists when creating their solar panel systems. The decision may hinge on several factors, such as intended electricity usage, available space, and desired voltage.

HOW CAN I IMPROVE THE EFFICIENCY OF MY HOMEMADE SOLAR PANELS?

Several strategies can improve the efficiency of homemade solar panels. Selecting high-quality solar cells is a crucial starting point, as the efficiency rating of solar cells can greatly affect overall output. Keeping the panels clean and free from obstructions, such as dirt or debris, enhances performance by maximizing sunlight exposure. Additionally, using optimal angles and orientations based on geographical location can significantly contribute to energy production. Temperature management is another aspect to consider; higher temperatures can reduce efficiency, so ensuring adequate airflow and using heat reflective materials can be beneficial. Lastly, incorporating MPPT (Maximum Power Point Tracking) technology can optimize energy production by dynamically adjusting the electrical load based on real-time conditions.

WHAT SAFETY MEASURES SHOULD BE TAKEN DURING INSTALLATION?

Safety precautions are paramount when working with electrical components in solar panel construction. Firstly, protective gear, such as gloves and goggles, should be worn to safeguard against burns or toxic fumes during soldering. Working in a well-ventilated area helps mitigate the inhalation of harmful chemicals found in solder. Ensuring the work surface is dry prevents electrical shocks, and double-checking connections before applying power minimizes shorts or failures. It is also essential to work with low-voltage equipment and familiarizing oneself with the electrical code to adhere to safety standards is imperative. Additionally, one should have a fire extinguisher ready on site, as a precaution for unforeseen incidents.

**The process of wiring the tubes of homemade solar panels involves several critical stages that require keen attention to both detail and safety. It begins with a thorough understanding of solar panel components and ensuring a well-prepared workspace. This foundation sets the stage for properly grasping wiring schematics, which is vital to achieving an efficient solar panel setup, allowing users to choose between series or parallel wiring configurations based on their energy needs.

As the project progresses into the wiring phase, securely placing the solar cells into the tubes and employing professional soldering techniques will help ensure that connections are not only functional but resilient against environmental factors. Proper insulation strategies further enhance the durability of the assembly, which is crucial for outdoor applications. Lastly, comprehensive testing will identify potential issues in connectivity or efficiency, allowing for adjustments that can optimize performance.**

In summary, each step has its own challenges and requirements, yet, when performed with meticulous care and thoughtful execution, the final product—a homemade solar panel—can provide reliable, renewable energy for various applications. This knowledge not only empowers individuals to harness solar energy but also contributes to a larger movement toward sustainable living. Engaging in the creation of solar panels fosters a deeper appreciation for alternative energy solutions and brings awareness to the potential that solar technologies hold for the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-wire-the-tubes-of-homemade-solar-panels/