1. THE IMPORTANCE OF WIRING A SOLAR REPLACEMENT SENSOR

2. UNDERSTANDING THE COMPONENTS OF A SOLAR REPLACEMENT SENSOR

3. STEP-BY-STEP WIRING PROCEDURE

4. COMMON ISSUES AND TROUBLESHOOTING OPPORTUNITIES

The solar replacement sensor is an integral component in a solar-powered system. Properly wiring this sensor can ensure efficient operation and longevity of the solar energy setup. 1. Incorrect wiring can lead to system failure, 2. Proper configuration maximizes energy efficiency, 3. Safety precautions are essential during installation. The most critical aspect of wiring the solar replacement sensor involves understanding the specific terminals and connections. This knowledge allows for precise connections, which optimizes signal transmission between the solar panel, the battery, and the load. The sensor functions to detect shifts in light levels, enabling effective energy management within solar-powered systems.

1. THE IMPORTANCE OF WIRING A SOLAR REPLACEMENT SENSOR

Embarking on the journey of installing a solar replacement sensor is pivotal for any solar energy enthusiast or professional. Understanding the significance of correct wiring cannot be overstated. Poor installations can result in inadequate system performance, compromised safety, and reduced lifespan of essential components. As solar technologies continue to evolve, the growing demand for efficient energy solutions necessitates precise and expert handling of equipment such as the solar replacement sensor.

The solar replacement sensor functions as the intermediary between solar panels and energy storage systems, regulating energy intake and output based on varying environmental light conditions. When correctly wired, it will sense the availability of sunlight and adjust the energy flow accordingly. The integration of this sensor thus not only enhances energy efficiency but also safeguards the system from potential damage caused by improper energy management. Therefore, understanding and executing proper wiring procedures becomes paramount for both novices and seasoned installers alike.

2. UNDERSTANDING THE COMPONENTS OF A SOLAR REPLACEMENT SENSOR

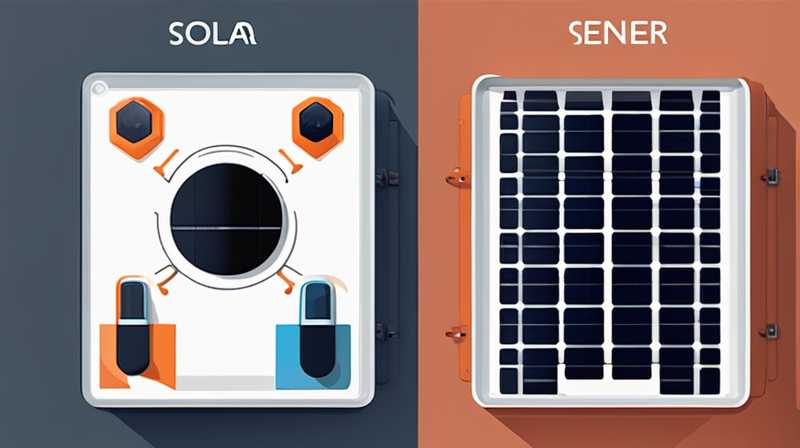

Before diving into the wiring intricacies, one must familiarize themselves with the core components of a solar replacement sensor. Typically, these sensors consist of several crucial elements, including sensing elements, connectivity terminals, and housing, among others. Each component plays a distinct role and contributes toward the overall efficiency and effectiveness of the sensor.

The sensing elements are responsible for detecting ambient lighting conditions. This aspect of the sensor adjusts the system’s response to available solar energy. Additionally, the connectivity terminals serve as the points of intersection where the sensor links with other parts of the solar system. Whether it is connected to a solar panel or a battery, ensuring a proper and secure connection is crucial for seamless functionality. Finally, the housing protects these sensitive components from external environmental factors, which could otherwise hinder performance or cause malfunctions.

3. STEP-BY-STEP WIRING PROCEDURE

Having comprehended the vital components, the next focus is on the wiring methodology. Wiring the solar replacement sensor involves several meticulous steps. The execution of each step should be performed with a detailed focus, ensuring that all connections are made accurately and securely.

Initially, gathering all necessary tools and materials is essential. These may include wire strippers, screwdrivers, and specific wiring connectors based on your solar energy setup. Once these items are at hand, electricity must be turned off to prevent any accidental electrical shocks during installation.

Next, identify the sensor’s connection points, which may be marked as positive and negative terminals. Connecting the positive wire from the solar panel to the positive terminal of the sensor ensures that the energy source feeds correctly into the system. Following this, the negative wire connection must be established. Lastly, ensure that the load, such as lights or batteries, connects adequately to the installation to allow for optimal power utilization.

4. COMMON ISSUES AND TROUBLESHOOTING OPPORTUNITIES

After completing the wiring, it’s prudent to anticipate potential issues that might arise. Common complications can include poor connections, environmental elements interfering with the sensor, or the sensor becoming non-responsive due to electrical faults. Understanding how to identify and troubleshoot these problems is essential for maintaining the efficiency of your solar system.

If the sensor appears unresponsive, first check the wiring connections for any loose or disconnected wires. A simple tightening or reconnection can resolve many issues. In addition, environmental factors such as dirt or obstructions affecting the sensor’s ability to detect light must be monitored and addressed. Regular maintenance and cleaning of the sensor are critical for flawless operation. Finally, if problems persist, consulting the manufacturer’s guidelines or seeking professional assistance could be necessary to prevent further complications.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF WIRE IS REQUIRED FOR SOLAR SENSOR WIRING?

Using appropriate wiring is essential to guarantee the optimal functioning and longevity of a solar replacement sensor. Generally, solar installations favor UV-resistant wires designed to withstand outdoor conditions, often provided as part of solar kits. The gauge of the wire may vary, generally falling between 14 and 10 gauge, depending on the distance from the solar panel to the sensor and the energy load being handled.

For extended wiring runs, opting for a larger gauge (smaller gauge number) helps minimize voltage drop, ensuring that adequate power reaches the sensor without loss of efficiency. Always consult specific recommendations provided by the sensor manufacturer or a qualified electrician to confirm that the right type of wire is selected. Using the appropriate wire can positively impact the system’s safety and performance.

HOW DO I KNOW IF MY SOLAR REPLACEMENT SENSOR IS WORKING PROPERLY?

Evaluating the functionality of your solar replacement sensor involves several diagnostic steps. Initially, monitor the operational status of your solar-powered system during various lighting conditions. The sensor should automatically detect changes in light and adjust the energy supply accordingly.

For instance, during daylight hours, the sensor should initiate energy uptake while conserving power at night. Additionally, visual inspection can reveal issues; check for any signs of damage, dirt-covered components, or loose connections that might impair its performance. If the sensor is not functioning correctly, perform step-by-step troubleshooting, examining all wiring and connections, and ensuring they align with operational specifications. If issues remain unresolved, consulting technical assistance may be necessary.

WHAT SAFETY CONSIDERATIONS SHOULD I BE AWARE OF WHILE WIRING A SOLAR REPLACEMENT SENSOR?

Safety should always be a priority when working on electrical devices, including solar replacement sensors. Before commencing any wiring, ensure that the system is powered down to eliminate the risk of electrical shock. Wearing insulated gloves and using insulated tools serves as additional precautionary measures.

Additionally, be mindful of the environment where the installation is taking place. Avoid working in wet or damp conditions and ensure the work area is well-lit to prevent accidental injuries. Furthermore, being familiar with local electrical codes and standards can provide guidance on safe practices. Educating oneself about these safety considerations can significantly reduce the likelihood of accidents occurring during the installation process.

FINAL REMARKS

Wiring a solar replacement sensor is crucial for ensuring the optimal performance of solar energy systems. The detailed steps required ensure that such installations contribute positively towards energy efficiency and safety. Each component, from the sensor itself to the wiring materials, must be carefully selected and connected to foster a reliable energy solution. Understanding the nuances of the sensor’s function and integrating it correctly is paramount for long-lasting applications within renewable energy domains.

Investment in proper tools and understanding the significance of safety measures while handling any electrical component is non-negotiable. Moreover, being equipped with troubleshooting strategies enhances the user’s capacity to maintain a functional and efficient solar system. Knowledge of the typical issues and timely responses to them can improve system longevity.

Ultimately, the greatest advantage comes from a commitment to continual education regarding advancements in solar technology and wiring techniques. Staying informed enables effective utilization of solar systems, leading to sustainable energy solutions that benefit the environment and reduce dependency on non-renewable resources. Those willing to invest effort into mastering the wiring of solar replacement sensors will find themselves able to sustain high-performance solar energy setups for many years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-wire-the-solar-replacement-sensor/