1. Introduction to Solar Thermal Insulation Pipe Sleeve:

Using a solar thermal insulation pipe sleeve effectively enhances heating systems by reducing heat loss and improving energy efficiency. 1. Optimization of energy use, 2. Enhancing system efficiency, 3. Reducing environmental impact, 4. Lowering operational costs. Each of these points directly contributes to a more sustainable energy solution. When utilized properly, solar thermal insulation pipe sleeves can prevent substantial thermal losses, which is particularly crucial in maintaining the temperature of the fluids circulating in solar heating systems. The insulation sleeve acts as a barrier, retaining heat and thus improving the overall efficiency of solar thermal systems.

1. IMPORTANCE OF SOLAR THERMAL INSULATION PIPE SLEEVES

In the world of renewable energy, thermal insulation plays a critical role in the performance of solar heating systems. To fully comprehend the significance of solar thermal insulation pipe sleeves, one must first recognize how heat transfer occurs in these systems. Heat transfer can be classified into three primary modes: conduction, convection, and radiation. Each of these modes must be minimized to ensure optimal functioning of solar thermal installations.

1.1 Impact on Heating Efficiency

By utilizing insulated pipe sleeves, the system experiences a remarkable increase in heating efficiency. The insulation minimizes the conduction of heat away from the pipe, ensuring that more of the energy generated by the solar collectors is delivered to the end-use application, such as water heating or space heating. When pipes are left uninsulated, significant heat losses can occur, sometimes exceeding 30%. Installation of thermal insulation effectively combats these losses, making it an essential practice for anyone looking to maximize the efficiency and performance of their solar thermal systems.

1.2 Costs and Energy Savings

Investing in quality insulation sleeves for pipe systems can lead to decreased operational costs over time. These savings arise from two primary aspects: reduced energy consumption and lower maintenance expenses. As the insulation retains more heat within the pipes, additional energy required to heat fluids is significantly lowered. In commercial and industrial applications, this can translate to substantial financial savings, while also making a meaningful contribution to environmental sustainability goals.

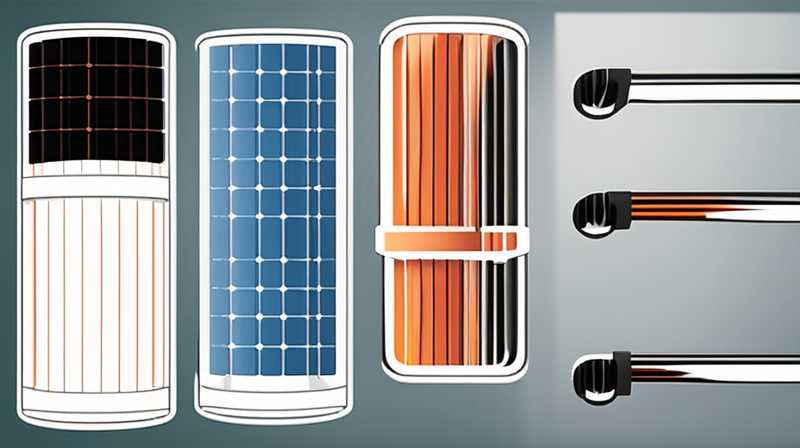

2. SELECTION OF THE RIGHT PIPE INSULATION

Choosing the appropriate type of insulation is vital for the effectiveness of thermal insulation pipe sleeves. Not every material is suitable for every application, and understanding the options available is essential for achieving the desired results.

2.1 Types of Insulation Materials

Common materials utilized for pipe insulation include fiberglass, polyurethane foam, and rubber. Each of these materials offers unique properties that can enhance performance in different environments. Fiberglass insulation is notable for its resistive qualities to high temperatures and is ideal when extreme conditions are present. Polyurethane foam boasts superior insulation values, yielding a higher R-value per thickness, thus requiring less space. Rubber insulation, on the other hand, is favored for its ease of installation and flexibility, making it particularly useful for irregularly shaped pipes or installation in confined spaces.

2.2 Considerations for Selection

While choosing insulation materials, various factors must be considered, such as the temperature range of the fluids being transported and the external environment. The thermal resistance, measured in terms of R-value, plays a crucial role in selecting the appropriate material. Additionally, factors like longevity, ease of maintenance, and installation costs should not be overlooked. By weighing these considerations, consumers can ensure they choose the most suitable insulation for their specific solar thermal applications.

3. INSTALLATION PROCESS OF PIPE INSULATION SLEEVES

With proper selection of pipe insulation sleeves completed, the next step involves an efficient installation process. An effective installation maximizes the performance of thermal insulation sleeves, allowing the system to operate at optimal efficiency.

3.1 Preparation Steps

Before initiating the installation, one must conduct a thorough evaluation of the existing piping system to determine any necessary repairs or modifications. The surface of the pipes should be cleaned to ensure that the insulation adheres properly. Furthermore, installation manuals and guidelines should be reviewed, as manufacturers often provide specific recommendations regarding installation techniques. Correct measurement of the pipe diameter is vital to ensure a proper fit; ill-fitting insulation is one of the leading causes of energy loss in thermal systems.

3.2 Installation Techniques

Installation techniques vary based on the type of insulation selected. For example, fiberglass insulation typically comes with a vapor-retardant facing that should be positioned toward the interior of the insulated area. For rigid foam insulation, the pieces need to be firmly adhered and sealed at joints to prevent any gaps. Rubber insulation is generally easier to work with, as it can often be slid onto the pipe, eliminating the need for adhesives. Proper sealing of seams—using tape or mechanical fasteners—is essential to minimize air infiltration. Careful attention to installation details ensures both the longevity and efficiency of the thermal insulation process.

4. MAINTENANCE OF THERMAL INSULATION PIPE SLEEVES

Following installation, regular maintenance of the thermal insulation sleeves is paramount to ensuring continued efficiency and performance of the heating system. Over time, wear and environmental factors can compromise the integrity of the insulation.

4.1 Regular Inspections

Conducting regular inspections of the insulation sleeves is essential. Signs of wear, tears, or detachment should be addressed immediately to prevent degradation of the insulation. The inspections should also focus on observing any moisture accumulation, as excessive moisture can lead to mold growth and consequently reduce the effectiveness of the insulation. Scheduling these evaluations at seasonal intervals can help in identifying potential problems before they escalate, ensuring the insulation maintains its optimal performance level.

4.2 Upkeep and Repairs

In the event of identified issues or damages, prompt repairs or considerations for replacements should be made. Products like sealing tapes or specialty adhesive can remediate minor tears or gaps effectively. For cases where significant damage is observed, complete replacement of affected sections may be warranted. In addition, keeping the insulation clean and free from debris aids in maintaining its effectiveness. Regular attention to maintenance can enhance not just the lifespan of the insulation but also the overall performance of the solar thermal system.

FREQUENTLY ASKED QUESTIONS

Q1: WHAT ARE THE BENEFITS OF USING SOLAR THERMAL INSULATION PIPE SLEEVES?

The implementation of solar thermal insulation pipe sleeves yields numerous advantages. Primarily, they significantly enhance the efficiency of heating systems by reducing thermal losses during the transfer of heated fluids. This efficiency boost leads to greater effectiveness in energy consumption, meaning that the system requires less energy to maintain desired temperature levels. Additionally, insulation sleeves help mitigate environmental impacts by utilizing renewable energy resources more effectively. By maintaining optimal temperatures, they can extend the lifecycle of the entire heating system, lowering maintenance demands and associated costs. Such benefits collectively contribute to a more sustainable energy initiative, making thermal insulation a vital aspect of solar thermal applications.

Q2: HOW DO I CHOOSE THE RIGHT TYPE OF INSULATION FOR MY SOLAR THERMAL SYSTEM?

When selecting appropriate insulation for a solar thermal system, key factors must be weighed carefully. First and foremost, it is essential to understand the temperature requirements of the fluids involved in the system; different insulation materials are rated for varying temperature ranges. Next, considering the environmental conditions surrounding the piping is crucial, as it may dictate the durability needed from the insulation material. Moreover, examining performance characteristics such as R-value, which measures thermal resistance, allows users to make informed decisions about which insulation will provide effective energy preservation. Finally, installation and maintenance considerations, such as costs, the availability of materials, and compatibility, should also guide decision-making to ensure the optimal selection for long-term performance.

Q3: HOW CAN I MAINTAIN MY SOLAR THERMAL INSULATION PIPE SLEEVES?

Proper maintenance of solar thermal insulation pipe sleeves is vital for sustaining their effectiveness over time. Regular inspections are necessary to identify any signs of wear, moisture accumulation, or physical damage to the insulation sleeves. If any issues are found, they should be addressed promptly to avoid compromising the insulation’s performance. Additionally, light cleaning of the insulation helps preserve its integrity by removing any debris that could trap moisture. For minor repairs, adhesive tapes or specific sealing compounds can be employed; however, significant damage may necessitate replacement of the affected sections. By committing to a routine maintenance schedule, users can maximize the lifespan and efficiency and ensure that their solar thermal systems operate at optimal levels.

5. Enhancing the Effectiveness of Solar Thermal Insulation Pipe Sleeves

Utilizing solar thermal insulation pipe sleeves presents an opportunity for optimizing energy efficiency. Designing a comprehensive approach that encompasses effective installation, regular maintenance, and informed material selection creates an ecosystem where sustainability and efficiency thrive. As the world increasingly adopts renewable energy technologies, strategies like these will become crucial in the pursuit of energy independence and environmental stewardship. The integration of thermal insulation not only enhances the performance of solar heating systems but also delivers financial savings and reduces waste. It stands as a testament to the ongoing evolution in our approach to energy consumption, reflecting a growing commitment to sustainable practices in building infrastructure and heating systems. When prospective users employ a strategic framework for the introduction and maintenance of thermal insulation, they unlock doors to greener energy solutions that provide lasting benefits to both users and our planet. With the foundational understanding established through robust knowledge, individuals and organizations alike are better prepared to harness solar energy’s full potential efficiently.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-use-solar-thermal-insulation-pipe-sleeve/