Understanding the methodology for utilizing solar pipe cutters, involves three primary approaches: 1. Familiarizing with the components and design of solar pipe cutters, 2. Applying correct techniques while cutting pipes, 3. Maintaining safety and efficiency throughout the process.

Solar pipe cutters are specialized tools designed to facilitate the cutting of pipes with precision, particularly in the context of solar installation projects. The primary aim of these tools is to simplify the process of cutting various types of piping materials, which are often used in solar energy systems, including PVC, copper, and polyethylene. Before diving into practical instructions, an understanding of the components and the methodology behind the operation of these cutters is essential.

1. INTRODUCTION TO SOLAR PIPE CUTTERS

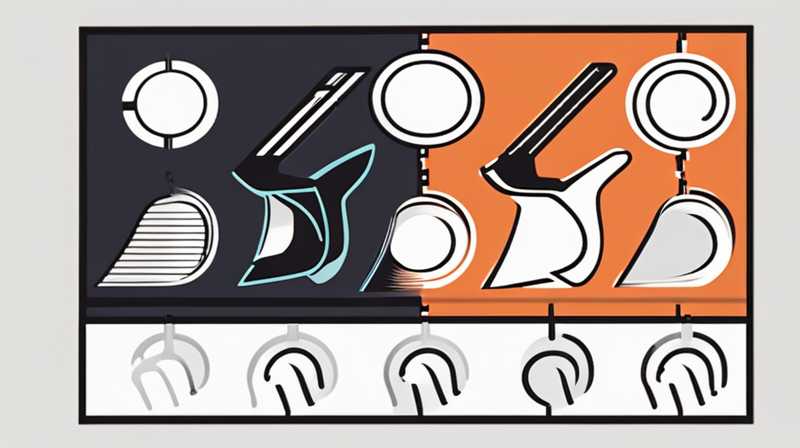

Solar pipe cutters have revolutionized the way installers handle piping materials. Unlike traditional saws or cutting tools, which can be cumbersome and dangerous, solar pipe cutters offer a streamlined design that enhances accuracy and ease of use. Typically, these tools feature a cutting wheel, a pipe adjustment mechanism, and ergonomic handles that facilitate better grip, reducing the amount of effort required during operation.

One of the primary advantages of utilizing solar pipe cutters is their ability to create clean, smooth cuts, which is highly beneficial when joining pipes together in solar installations. These tools are especially designed to prevent burring and distortion of the pipe ends, which may compromise the integrity of the connections in a solar energy system. Unlike methods involving manually-powered saws, the use of solar pipe cutters leads to increased efficiency—allowing professionals to complete tasks swiftly while ensuring the installation’s quality remains uncompromised.

2. COMPONENTS OF A SOLAR PIPE CUTTER

Understanding the different components of a solar pipe cutter is vital for effective use. The cutting wheel or blade is the key part that executes the cutting action. Depending on the type of material being cut, these blades can vary in construction and material. High-quality tungsten carbide or specialized steel blades are common, allowing for durability even under rigorous conditions.

The adjustment mechanism is another critical component, often featuring a rotary system that accommodates different pipe diameters seamlessly. This adjustability ensures that the cutter can be utilized across various applications, reducing the need for multiple tools in a single project. Additionally, the ergonomic handles enhance comfort during prolonged use, minimizing hand fatigue and promoting a more efficient working process.

3. PREPARATION BEFORE CUTTING

Prior to engaging the pipe cutter, meticulous preparation is paramount. Initially, always ensure the workspace is clean and free from obstructions. Gather the necessary safety equipment, including protective eyewear, gloves, and appropriate attire designed for construction or mechanical work. These measures not only protect the individual operating the cutter but also enhance overall project safety.

Next, prepare the pipe material. This involves measuring and marking the desired cut location on the pipe. Accuracy during this step is crucial; a precise marker will yield a better-fitting joint later in the installation process. After marking, double-check measurements to ensure alignment with project specifications. This step reinforces the importance of precision in solar installations where exact fittings and connections contribute to overall efficiency.

4. OPERATING THE SOLAR PIPE CUTTER

The operation of a solar pipe cutter is straightforward; however, proper technique is crucial for achieving optimal results. Begin by inserting the pipe into the cutter’s designated opening, ensuring the marked line is aligned with the cutting wheel. Once the pipe is securely placed, tighten the adjustment mechanism to hold the pipe firmly in place.

With the pipe securely positioned, initiate the cutting process by applying a moderate amount of pressure while turning the handle or activating the cutting mechanism, depending on the model. Maintain a consistent speed and pressure throughout the cutting process. It is important not to rush this step, as uneven pressure can lead to jagged cuts or damage to the pipe. Upon completion, gently unlock the cutter and remove the pipe, inspecting the cut for any imperfections or irregularities.

5. MAINTENANCE AND SAFETY

Maintaining solar pipe cutters is essential for longevity and continued performance excellence. After utilizing the tool, clean the cutting wheel and body to remove any debris or plastic remnants. Consistent cleaning minimizes wear on the blades and prevents corrosion or damage. Periodically check the alignment of the cutting wheel and adjustment mechanism to ensure smooth operation.

Safety measures play a pivotal role in the utilization of these tools. Always inspect the cutter for any signs of damage before use; a compromised tool can be unsafe and lead to accidents. Furthermore, employ safe handling practices, such as storing tools out of reach of children, and ensure that all users are trained on proper operation procedures for the respective solar pipe cutter employed during installation tasks.

6. COMMON APPLICATIONS FOR SOLAR PIPE CUTTERS

Solar pipe cutters are utilized across various applications within the renewable energy sector. Predominantly, they are employed for the installation of solar water heating systems, where precise cuts in pipes are vital for optimal fluid dynamics and heat exchange efficiency. These systems often utilize polybutylene or PVC pipes, which are increasingly favored for their flexibility and resistance to heat, making them an ideal fit for solar applications.

Additionally, solar pipe cutters play a role in photovoltaic (PV) installations, particularly when it comes to managing conduit systems that house electrical wiring. Effectively routing wires through properly fitted conduit ensures effective connectivity and minimizes the risk of electrical malfunctions. The versatility of solar pipe cutters allows for their application across various renewable installations, reaffirming their essential status in the solar industry.

7. ADVANCED TECHNIQUES FOR EFFECTIVE USE

For seasoned professionals seeking to enhance their skills, advanced techniques can be employed alongside standard practices. One method involves the use of guide strips, which help maintain alignment when cutting longer sections of pipe. This technique not only aids in achieving greater accuracy but also empowers installers to handle more complex projects that require longer, more precise cuts.

Furthermore, investing in self-feeding solar pipe cutters can significantly increase efficiency. These models feature automatic cutting actions that can save time during large installations, allowing workers to focus on other essential tasks. Training sessions around advanced techniques can further empower teams, ensuring collective proficiency in handling specialized tools effectively, particularly under time-sensitive project conditions.

8. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

The usage of solar pipe cutters ties into a greater commitment to environmental sustainability. Efficient cutting tools reduce waste materials by facilitating cleaner cuts, thus minimizing the surplus of unusable pipe sections. Additionally, the adoption of practices that emphasize quality and precision directly contributes to the overall energy efficiency of solar systems. As installations become more proficient and waste products are decreased, the ecological footprint of solar energy projects diminishes over time.

Furthermore, the choice of sustainable materials in conjunction with responsible methodologies reinforces the environmentally conscious ethos within the solar industry. Professionals should adopt a holistic view of sustainability by not only focusing on the energy output of solar systems but also considering the tools and methodologies employed in constructing these installations.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF PIPES CAN SOLAR PIPE CUTTERS BE USED ON?

Solar pipe cutters are designed to work on a variety of piping materials commonly found in solar energy applications. These include PVC, copper, and polyethylene pipes. PVC is popular for solar thermal systems, while copper is often utilized for its excellent thermal conductivity. Polyethylene is also frequently employed due to its durability and resistance to harsh environmental factors. The flexibility of solar pipe cutters allows them to be adapted for various pipe diameters and thicknesses, ensuring that installers can work efficiently regardless of the material being used. However, it is crucial to use the appropriate cutter for each specific pipe type to maintain cutting effectiveness and prevent damage to the tool or the material.

HOW DO I MAINTAIN A SOLAR PIPE CUTTER?

Maintaining a solar pipe cutter involves several key steps to ensure its longevity and effectiveness. Firstly, clean the cutter after each use; debris can accumulate and affect performance. Regularly inspect the cutting wheel for wear and replace it when necessary. Lubricating moving parts can also improve functionality and decrease friction that can cause wear over time. Furthermore, always store the cutter in a protective case or designated space to prevent accidental damage and ensure it remains in top condition for future uses. Keeping the tool dry and free from moisture will also aid in preserving its integrity against rust and corrosion.

ARE THERE ANY SAFETY PRECAUTIONS I SHOULD TAKE WHEN USING A SOLAR PIPE CUTTER?

Absolutely, safety precautions are paramount when utilizing a solar pipe cutter. Always wear appropriate protective gear, including safety glasses and sturdy gloves, to shield against any accidental injuries. Ensure the workspace is clear of obstacles, and consider wearing a hard hat if working in a high-risk area. Before initiating any cuts, inspect the tool for damage, as utilizing a compromised cutter can lead to accidents. Moreover, maintain a focused and steady hand during operation, avoiding distractions to ensure precision. These measures will significantly minimize the risk of injury and enhance overall productivity during the installation process.

In summary, utilizing solar pipe cutters efficiently combines knowledge of the components, operation techniques, maintenance, and safety. Effective application of these tools is imperative in ensuring the success of solar installation projects. Commitment to proper usage and comprehensive understanding of the practices surrounding solar pipe cutters ultimately leads to exalting results, reflecting the high standards prevalent in today’s renewable energy industry. As skilled professionals embrace these tools, they will undoubtedly push the envelope of solar innovations, setting new benchmarks in operational effectiveness and eco-consciousness.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-use-solar-pipe-cutters/