To transport solar glass tubes effectively, several essential considerations must be taken into account to guarantee their safety and integrity throughout the process. 1. Choose appropriate packaging materials, 2. Implement proper handling techniques, 3. Ensure appropriate stacking methods, 4. Monitor environmental conditions. Among these points, choosing the right packaging materials deserves a detailed exploration as it is crucial for protecting the tubes from potential damage during transportation. Specialized cushioning materials such as foam inserts or bubble wrap should be employed to prevent movement and absorb shocks, while heavy-duty cardboard boxes or crates should be utilized to provide a sturdy outer shell. Additionally, labeling boxes with clear instructions regarding fragile contents will inform handlers about the care needed during loading and unloading. When all these strategies are combined, they will minimize the risk of breakage and maintain the quality of the solar glass tubes until they reach their destination.

1. CHOOSING APPROPRIATE PACKAGING MATERIALS

Successful transportation of solar glass tubes starts with the selection of appropriate packaging materials. Given the fragile nature of glass, utilizing specialized packaging systems is critical for minimizing the risk of breakage. Various materials are available that can offer an adequate level of protection. For instance, heavy-duty cardboard or wooden crates can provide a solid external layer, preventing crushing forces during transit.

Moreover, the interior of the packaging should be lined with soft padding materials, such as foam or bubble wrap, to absorb shocks and impacts. Foam inserts, specifically designed for glass tubes, can cradle the individual items securely, preventing them from moving in transit. This careful attention to the choice of packaging ensures that the solar glass tubes remain intact, regardless of the external conditions they might encounter.

2. IMPLEMENTING PROPER HANDLING TECHNIQUES

Handling procedures during loading and unloading play a significant role in ensuring the intact delivery of solar glass tubes. Employing trained personnel who understand the fragile nature of the product is paramount. When loading the tubes, workers should lift them using both hands, supporting the length of the tube to distribute the weight evenly. This method reduces the risk of stress that could lead to cracks or shattering.

Additionally, utilizing mechanical aids, such as forklifts or pallet jacks, can help in moving larger quantities of tubes. These machines minimize manual handling, which can often lead to accidents or mishandling. Clear protocols regarding the use of these machines should be established and consistently implemented to further ensure safety during the transportation process.

3. ENSURING APPROPRIATE STACKING METHODS

Once the solar glass tubes are packed and ready for transport, the stacking methods used in the vehicle or shipping container become crucial. Tubes should be stacked vertically rather than lying flat to provide stability and support. Moreover, it’s important to avoid overloading stacks, as excessive weight can lead to crushing incidents, ultimately risking the integrity of the glass.

Utilizing separators or dividers can enhance protection by preventing tubes from coming into contact with each other and causing chafing or breakage. Appropriate spacing between stacks also allows for ventilation, which is important for temperature-controlled transport. Ensuring all safety guidelines are followed during the stacking process is vital to preventing potential losses.

4. MONITORING ENVIRONMENTAL CONDITIONS

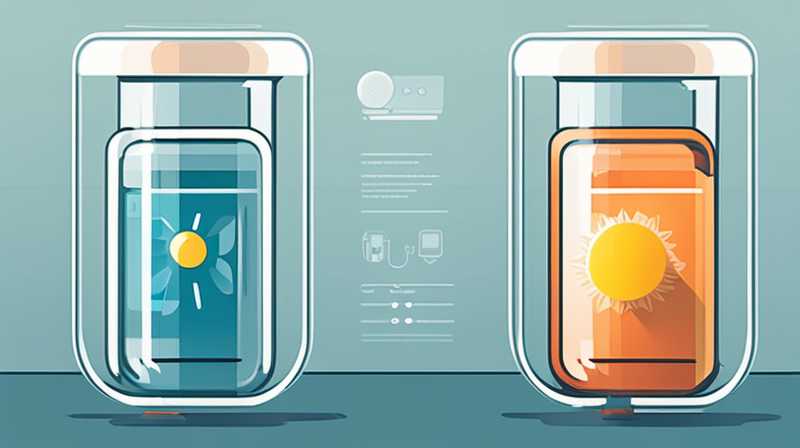

Another critical aspect of transporting solar glass tubes is monitoring environmental conditions. Fluctuations in temperature and humidity can greatly influence the material properties of glass, making it imperative to maintain a stable environment during transportation. Utilizing climate-controlled vehicles can mitigate the risk of any adverse effects caused by extreme temperatures, moisture, or exposure to direct sunlight.

Regular inspections of the shipping environment should be a standard procedure. This includes checking the stability of temperature and humidity levels periodically throughout the journey. Additionally, employing temperature and humidity loggers can provide real-time data, ensuring the conditions are consistently within the acceptable range. This proactive approach can prevent potential damages due to environmental stresses.

FAQs

WHAT TYPES OF PACKAGING ARE BEST FOR SOLAR GLASS TUBES?

The ideal packaging materials for solar glass tubes include heavy-duty cardboard boxes or wooden crates that provide sturdy external protection. Internally, soft padding like foam or bubble wrap is essential to cushion the tubes during transit, minimizing the risk of breakage. Custom inserts are often created specifically for these tubes to support them securely and prevent movement within the packaging. The emphasis on quality packaging is not merely a precaution; it directly influences the likelihood of the tubes arriving at their destination without damage.

HOW CAN I ENSURE SAFE HANDLING OF SOLAR GLASS TUBES DURING LOADING AND UNLOADING?

Ensuring safe handling of solar glass tubes involves several best practices. Firstly, personnel should be properly trained in handling fragile products. They should use both hands when lifting, evenly supporting the length of the tube. Additionally, the use of mechanical aids, like forklifts, reduces the necessity for manual handling, further lowering the risk of accidents. It is also beneficial to establish clear protocols for loading and unloading operations to maintain consistency in safety practices across the workforce. Regular training refreshers may help keep safety at the forefront of handling policies.

WHAT ENVIRONMENTAL CONDITIONS ARE IMPORTANT TO MONITOR DURING TRANSPORT?

Two primary environmental conditions to monitor during transport are temperature and humidity. Fluctuations in these factors can adversely affect glass materials. For climate-sensitive products like solar glass tubes, employing temperature and humidity loggers that provide continuous, real-time readings helps in ensuring the conditions remain stable throughout the journey. In some cases, climate-controlled vehicles may be necessary, particularly for longer transport distances or where extreme environmental factors can be expected. Ensuring the correct environment is maintained directly impacts the integrity of the glass once it arrives at its destination.

Transporting solar glass tubes necessitates meticulous planning and execution to ensure their protection and integrity throughout their journey. By concentrating on selection of the right packaging materials, employing proper handling techniques, ensuring stacking safety, and monitoring environmental conditions, it is possible to significantly reduce the likelihood of breakage during transit. This comprehensive approach not only safeguards the investment in solar glass tubes but also contributes to overall efficiency in logistics. Additionally, robust training for personnel in safe handling practices and consistent monitoring of transport conditions play crucial roles in achieving successful outcomes. In this context, one should recognize the importance of adopting a preventative mindset, as it is always more effective to mitigate risks before they manifest. Ultimately, each step taken in the logistics process contributes to a more secure transport experience, ensuring solar glass tubes arrive at their destination intact and ready for installation. This thorough diligence in transport logistics also enhances customer satisfaction, reinforcing the value of quality control in the solar energy industry.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-transport-solar-glass-tubes/