To tighten the solar countercurrent tube effectively, individuals should follow a systematic approach involving: 1. Identifying the tube type and configuration, 2. Utilizing appropriate tools and materials, 3. Ensuring safety protocols are adhered to, 4. Applying proper tightening techniques. Detailed elaboration is warranted, particularly on the third point: Adhering to safety protocols is crucial to prevent accidents, ensure equipment longevity, and avoid damaging the system. This entails wearing protective gear, ensuring that the system is de-pressurized, and conducting thorough inspections prior to any adjustments.

1. UNDERSTANDING SOLAR COUNTERCURRENT TUBES

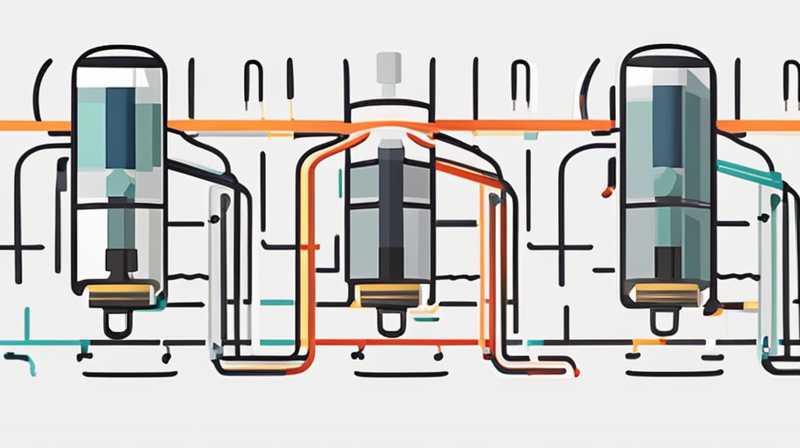

Solar countercurrent tubes play a pivotal role in solar heating systems. They are designed to enhance efficiency by allowing heat exchange between fluids moving in opposite directions. This mechanism maximizes energy transfer, ensuring that heated fluid emerges from the heat exchanger while cooler fluid enters, enhancing the overall efficiency of the solar heating process. In analyzing the importance of these tubes, one must consider their material composition and installation methodology.

These tubes can be constructed from various materials, including copper, aluminum, and specialized polymers. Choosing the right material is essential as it affects both the thermal conductivity and durability of the components. Copper, for instance, has excellent thermal conductivity properties, making it a popular choice for many applications. However, it may be prone to corrosion if not properly maintained, which underscores the importance of ensuring that connections remain solid and secure.

Moreover, the installation procedure can heavily influence the performance and longevity of the solar countercurrent tube. An inadequately installed tube can lead to air bubbles or leaks, which can compromise efficiency and lead to costly repairs down the line. Special attention must be given to the alignment and fittings when securing replacements or new installations.

2. TOOLS AND MATERIALS REQUIRED

Navigating the process of tightening solar countercurrent tubes requires specific tools and materials. The choice of tools directly affects the quality of the tightening process. Pliers, wrenches, and screwdrivers are essential for handling various fittings and connections. Additionally, one may require specialized equipment like torque wrenches to ensure that the connections are adequately secured.

The selection of appropriate materials is equally vital. Depending on the types of fittings used, one might need specific seals and gaskets, often made from rubber or silicone. These elements prevent leaks and ensure a solid connection between components. It is essential to utilize quality sealants that can withstand the operating temperatures of solar systems. For example, selecting a high-temperature silicone sealant can greatly improve the integrity and durability of the assembly, especially in systems exposed to changing weather conditions.

Preparation is critical when embarking on this tightening task. Before starting, individuals should gather all necessary tools and materials, laying them out in an organized manner. This approach minimizes disruption and ensures that the tightening process proceeds smoothly and efficiently.

3. SAFETY PROTOCOLS

Prioritizing safety when dealing with solar countercurrent tubes cannot be overstated. The procedures involved can pose potential risks; hence adhering to established safety protocols is indispensable. Safety gear, such as gloves and goggles, should be donned prior to commencing any work. This protective equipment is critical in safeguarding against potential injuries from sharp edges, hot components, or sudden releases of pressure.

Another significant aspect involves acknowledging the system’s pressure levels. Before any manipulation takes place, the system should be depressurized. This step is crucial as working with pressurized systems presents the danger of sudden releases that can lead to severe burns or mechanical injuries. Individuals can often find depressurization instructions in the system’s manual, ensuring that no steps are overlooked.

Regular inspections of the system components are also a relevant safety measure. When tightening components, taking a moment to check for wear or damage can avert future complications. For instance, fraying on hoses or corrosion on fittings may indicate a need for replacement rather than simple tightening. Such proactive evaluations not only enhance safety but also prolong the lifespan of the entire system.

4. PROPER TIGHTENING TECHNIQUES

Employing correct tightening techniques is paramount for ensuring the effectiveness of solar countercurrent tubes. Inadequate tightening can result in leaks, while over-tightening can lead to structural damage. To undertake the task correctly, one must first understand the type of fitting used—compression fittings, for instance, require a different approach compared to threaded connections.

A systematic approach often yields the best results. Begin with hand-tightening—this allows for alignment of the components without overexerting force. Following initial hand-tightening, utilizing a wrench or pliers to further secure the connections is necessary. It is essential to tighten progressively; that is, don’t over-torque any single connection before assessing the entire assembly. This technique minimizes stress concentrations that can lead to failure points.

Another key point to remember is that many systems will have torque specifications outlined in their manuals. Adhering to these specifications prevents potential damage that excessive force might cause. A torque wrench is invaluable for this purpose, providing precise measurements that help maintain the integrity of the components while ensuring a leak-proof seal.

5. VALIDATING THE INTEGRITY OF CONNECTIONS

After concluding the tightening process, validating the integrity of connections is a vital step that must not be overlooked. Conducting a thorough inspection for potential leaks or weaknesses is essential. One effective way to check for leaks is to pressurize the system and observe for any signs of fluid escape, which may manifest as drips or a visible damp area around the connections.

Additionally, utilizing a leak detection solution can enhance confidence in the integrity of the assembly. Such solutions create visible bubbles upon contact with escaping fluid, providing a clear indication of failure points. If a leak is located, the corresponding fitting should be re-evaluated and adjusted accordingly.

It is advisable to allow the system to run for a short period post-tightening to confirm operational integrity. Monitoring performance can provide insights into temperature fluctuations and flow rates, which are essential indicators of system efficiency. If any fluctuations occur beyond expected limits, further investigation is warranted, as this may indicate underlying issues requiring attention.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON SIGNS THAT A SOLAR COUNTERCURRENT TUBE NEEDS TIGHTENING?

There are several indicators that signify the necessity for tightening solar countercurrent tubes. Owners may notice leaks or dripping fluids around connection points, which serves as a primary symptom. This situation often results from insufficiently tightened fittings or degradation of seals. Additionally, persistent temperature inconsistencies in the system may indicate that the flow of the working fluid is being impeded due to air locks or pressure losses at compromised connections.

Another noteworthy sign is auditory cues, such as hissing sounds emanating from the system, which may suggest escaping gases or fluids. Should these symptoms present themselves, it becomes crucial to conduct a complete diagnostic evaluation of the assembly and determine if tightening or replacement of components is warranted. Continuous monitoring serves to prevent further damage and ensure the sustained efficacy of the solar heating system.

HOW OFTEN SHOULD I CHECK THE SOLAR COUNTERCURRENT TUBE?

The frequency of inspections for solar countercurrent tubes should be influenced by various factors, including the system’s age, operating conditions, and previous maintenance history. As a standard guideline, annual inspections are generally recommended. Such evaluations through seasonal transitions can uncover any deterioration arising from environmental exposure, temperature fluctuations, and operational wear over time.

In addition to routine checks, it is prudent to assess the system after extreme weather events. Conditions such as strong winds, heavy rain, or temperature spikes can stress the equipment, potentially compromising connections or the structural integrity of the components. Therefore, vigilant attention should be paid following such events, enabling early identification and rectification of issues.

Lastly, personal observations during other maintenance processes can provide valuable insights. For instance, noting any visual signs of wear, cracks, or corrosion may prompt more frequent checks in particular areas, thereby ensuring that system integrity is continuously maintained.

WHAT SHOULD I DO IF TIGHTENING DOES NOT SOLVE THE PROBLEM?

If tightening the solar countercurrent tube does not rectify the existing issues, one must consider various avenues for further investigation. The initial step involves verifying the integrity of the fittings. Damage or excessive wear present on components could necessitate their replacement rather than simply tightening.

Additionally, consider checking for issues beyond the tubes themselves. Possible blockages within the system, such as debris or sediment buildup, might impair fluid flow. Utilizing filters is a proactive strategy to prevent such occurrences. Should these blockages be suspected, cleaning solutions or mechanical cleaning methods can be employed to restore optimal flow conditions.

Moreover, consulting a professional specializing in solar systems may provide insights and solutions that are not immediately evident. Seeking expert advice is particularly valuable when systems exhibit persistent complications, as it ensures that maintenance actions are properly informed and yielded efficacious results. Remember, timely resolution of issues prevents deterioration of system performance and avoids costly damages.

Proper maintenance of solar countercurrent tubes is essential for ensuring long-term efficiency and performance. Each phase of the inspection and tightening requires diligence and knowledge of both the system and the procedures involved. By following the steps outlined, individuals not only maintain the functionality of their solar heating systems but also contribute to energy efficiency and sustainability efforts. It is evident that understanding the components, utilizing the proper tools, adhering to safety protocols, and employing correct techniques are ingrained in achieving optimal results. Therefore, fostering an informed approach to maintenance will ultimately maximize the utility gained from these solar systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-tighten-the-solar-countercurrent-tube/