Tying the solar solenoid valve wire necessitates careful attention to detail to ensure functionality and reliability. 1. Gather appropriate tools and materials, 2. Identify the correct wiring connections, 3. Strip and prepare wire ends, 4. Securely connect wires using appropriate techniques. The preparation phase is crucial; using the right tools such as wire strippers, connectors, and insulating tape will enhance the integrity of the connections. Proper identification of the wiring connections is vital to avoid misconfiguration. Ensuring that the solenoid valve operates efficiently requires precise execution of the wiring process.

1. UNDERSTANDING SOLENOID VALVE WIRING

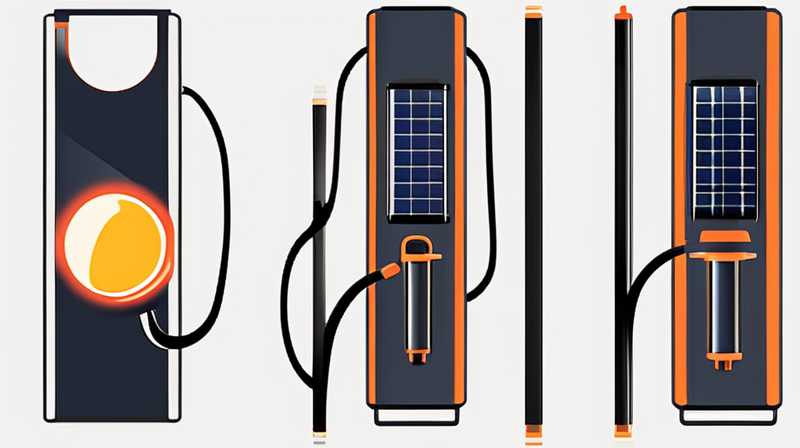

The solenoid valve serves as a critical component in various irrigation systems, utilizing electric current to open or close the valve based on controlling mechanisms. A solar solenoid valve is environmentally friendly, reducing reliance on traditional power sources while still providing efficiency. The wires connected to the solenoid must be appropriately tied to maintain a stable operation. Understanding the components involved in wiring will foster a smoother and more effective installation.

Before engaging in the practical aspects of tying the solar solenoid valve wire, it is essential to understand the purpose of each wire involved. Typically, a solenoid valve features a positive and negative wire connection. The positive lead connects to the power source, while the negative lead acts as a return path for the current. Correctly identifying these connections is paramount, as improper wiring can lead to malfunction or even damage to the valve.

2. PREPARING TO TIE THE SOLENOID VALVE WIRE

Preparation is often the key to success when engaging in wiring activities. Gathering the correct tools and materials lays the foundation for a successful and safe wiring process. The following items are necessary: wire strippers, connectors, electrical tape, a multimeter, and a suitable workspace. Ensuring that the work environment is organized and free from distractions will enhance focus and minimize the risk of mistakes.

Before stripping the wires, verifying the specifications of the solenoid valve is crucial. Each component may have varying voltages and current requirements. Consulting the manufacturer’s manual will provide detailed information on the recommended wire types and gauges. Once this information is obtained, the process of stripping the wires can commence; every lead must be stripped to an appropriate length, exposing enough copper to form a secure and effective connection while preventing excess exposure that could lead to shorts or corrosion.

3. CONNECTING THE SOLENOID VALVE WIRES

With the preparatory work completed, the next step involves engaging in the actual wiring process. Ensuring that connections are reliable and insulated adequately safeguards against electrical issues down the line. Utilizing connectors appropriate for the wire gauge helps to ensure that connections remain intact under various operating conditions.

Once the wires are stripped, the positive wire should be connected first. This wire will generally be colored in a specific manner to differentiate it from the negative wire. Using a connector such as a wire nut or crimp connector will create a solid connection. In situations where the connector is crimped, ensuring it is tightly secured is essential to prevent any loosening over time. The negative wire should follow; similarly, using an appropriate connection method is crucial for overall stability.

4. SECURING AND INSULATING THE CONNECTIONS

Upon successfully connecting the solenoid valve wires, the next phase consists of securing and insulating these connections. Electrical tape or heat-shrink tubing offers reliable protection against moisture and accidental contact with conductive surfaces. Proper insulation helps to ensure that no part of the wire exposed to the environment can lead to shorts or other electrical issues that might interfere with the operation of the solenoid valve.

To apply electrical tape, wrap it around each connection point several times, ensuring that not only the exposed wire is covered but also a bit of the insulation above and below the connection. Heat-shrink tubing, when applicable, requires heating to seal the tubing around the exposed sections. This method creates a more robust protective barrier, especially in outdoor environments exposed to the elements.

FAQs

WHAT IS A SOLENOID VALVE, AND HOW DOES IT WORK?

A solenoid valve is an electromechanical device used to control the flow of fluids in plumbing and irrigation systems. It operates by using an electromagnetic solenoid coil that, when energized, pulls a plunger up or down to either open or close the valve. In essence, when current flows through the coil, it creates a magnetic field that moves the plunger, regulating fluid passage. Solenoid valves can be found in a variety of applications, such as irrigation systems, automotive fields, and industrial controls, demonstrating their wide-ranging utility.

The ability to actuate flow electronically makes solenoid valves highly effective for automated systems. For example, in irrigation, they enable precise control, allowing the system to conserve water and optimize distribution based on specific programmed settings. Their reliability and efficiency serve as compelling reasons for their popularity, making them a staple in systems requiring remote or automated operation.

HOW MANY WIRES ARE TYPICALLY FOUND ON A SOLENOID VALVE?

Typically, a standard solenoid valve incorporates two wires — one for the power connection and another for grounding. In some cases, variations may occur depending on the model and design used. Certain solenoid valves, particularly those designed for more complex operations, may feature additional wires for enhanced functionalities. These additional wires could be employed for feedback mechanisms or for connecting to control systems with precise functionality.

The basic dual-wire configuration is prevalent due to its simplicity, as one wire carries the current while the other serves as a return path. For users engaging with solenoid valves, understanding the specific wiring layout is crucial. Familiarity with the wiring system ensures that the valve operates without misconfiguration, imparting confidence in its performance.

HOW CAN ONE ENSURE THAT CONNECTIONS ARE SECURED AFTER TIEING THEM?

To validate that connections remain securely tied, effective measures such as performing operational tests and visual inspections can be employed. Once wiring is completed, it’s advisable to activate the solenoid valve to determine its responsiveness. If the valve functions as intended, this serves as an initial confirmation of a successful connection.

Moreover, periodic inspections can help in identifying potential issues, such as fraying wires or loosened connectors. Keeping a close watch on the wiring over time ensures that no future outages occur due to neglect. Proper insulation and securing methods also play a significant role in long-term integrity, as they safeguard against various environmental factors influencing the durability of the wiring.

Taking into account the complexity of tying the solar solenoid valve wire, maintaining focus on detail is essential. Start with appropriate tools and materials, and comprehensively understand the function of each wire involved. Gradually follow the steps, ensuring wires are securely connected and insulated against factors that may compromise their integrity. By carefully monitoring the functionality after installation and conducting routine inspections, the reliability and performance of the solar solenoid valve can be assured, paving the way for effective regulation of fluid flows in an eco-friendly manner.

Expertise in tying the solar solenoid valve wire renders the user empowered to manage their irrigation systems efficiently. Using advanced understanding and techniques will not only enhance the installation process but ensure longevity in the product. The environment benefits from employing solar technology, making it an essential component in sustainable practices. Careful attention to every step involved in tying the wires will yield satisfactory results, transforming the electrical connection capabilities in various applications, particularly in irrigation. Ultimately, taking the time to master this skill will undoubtedly enhance the user’s competence in managing more intricate irrigation systems, furthering the adoption of solar solutions in everyday practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-tie-the-solar-solenoid-valve-wire/