To thread solar power wires effectively, it requires a methodical approach that ensures safety and functionality. 1. Prepare your workspace, 2. Gather the necessary tools, 3. Follow safety precautions, 4. Identify wire types and connections. Preparing your workspace involves ensuring it’s clean and organized to minimize mistakes. One critical element is understanding the types of wires used in solar power systems, including positive, negative, and ground wires. For instance, the solar panel’s positive wire is typically red, while the negative wire is black. This color-coding is vital for successful installation and to prevent errors that can lead to equipment failure or hazards.

1. UNDERSTANDING SOLAR POWER WIRE CONFIGURATION

Before embarking on the process of threading wires, comprehending the layout within a solar power system is essential. Solar systems consist of various configurations, including series and parallel wiring. In a series configuration, voltages are added together while maintaining the same current level, meaning that if one panel fails, the entire string might be affected. Alternatively, a parallel setup maintains the same voltage while combining the current, ensuring that power remains available even if one panel becomes non-operational.

Knowing when to utilize each configuration is critical. For instance, in residential applications, a combination of series and parallel connections might be deployed to balance voltage and current effectively, optimizing energy output. Therefore, familiarizing oneself with these configurations not only aids in efficient wire threading but also impacts the overall efficiency of the solar installation.

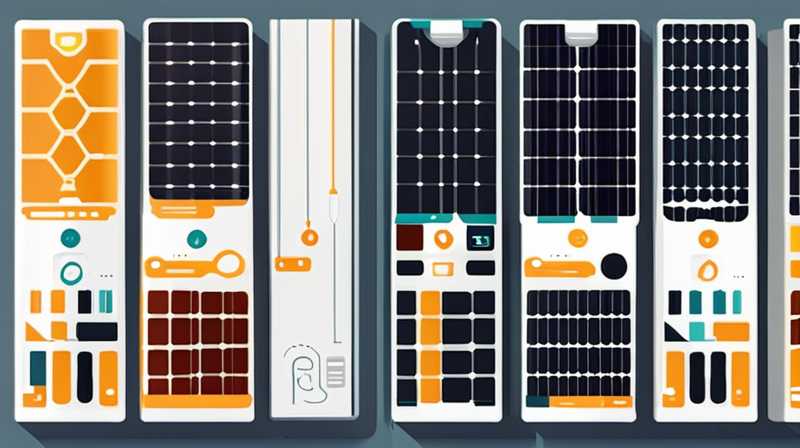

2. TOOLS REQUIRED FOR THREADING SOLAR POWER WIRES

Equipping oneself with the right tools significantly influences the ease of threading solar power wires. Key tools include wire strippers, crimping tools, and various connectors. Wire strippers allow for the precise removal of insulation from the wire ends, which is a crucial step before making any connections. A crimping tool secures the connectors firmly onto the wire ends, ensuring a solid electrical connection that can withstand harsh weather conditions.

In addition to these tools, having electrical tape and zip ties on hand can facilitate organizing and insulating the wires during and after installation. Adhering to best practices with your tools not only enhances safety but also prolongs the longevity of your solar power system. Thus, taking the time to gather the right equipment pays dividends in performance and reliability.

3. SETTING UP SAFETY MEASURES

Implementing safety measures is paramount when working with electricity, including solar power installations. Wearing personal protective equipment (PPE) such as gloves and safety goggles is a must. This precaution protects against accidental contact with electrical components and minimizes risk when handling sharp tools.

Moreover, ensuring that the solar power system is turned off before beginning any work is critical. Always double-check the power status with a multimeter to confirm that no voltage is present. Understanding how to work with electricity safely can prevent accidents and create a smooth installation process. Proper training, combined with adherence to safety guidelines, instills confidence and fosters a secure working environment.

4. IDENTIFYING SOLAR POWER WIRE TYPES

Solar power systems utilize specific wire types that are designed to handle the environmental stressors of outdoor use. Typically, solar wires are made of durable materials such as Teflon and are UV rated to withstand sunlight exposure. Moreover, these wires are often rated for higher temperatures, which is essential in maintaining performance efficiency.

Common wire types include Photovoltaic (PV) wire, which is specifically utilized for connecting solar panels to the inverter and battery systems. Understanding the specifications of these wires, including gauge and length, ensures appropriate current handling. Longer runs may require thicker wires to reduce voltage drop and maintain system efficiency over distance. Recognition of the right wire types according to application and environment significantly enhances effective wire threading, tapering down potential issues down the line.

5. THREADING PROCESS OF SOLAR POWER WIRES

The threading process itself is a fundamental part of the installation that requires careful execution. Start by planning the pathway through which the wires will run. Ideally, wires should be routed in a manner that minimizes exposure to potential hazards while ensuring they are secured adequately along the installation. Proper wire management aids in preventing tangling and enhances the overall aesthetic of the installation.

Begin threading with the positive wire from the solar panel leading towards the charge controller. Utilizing cable conduits or cable trays can protect the wires from environmental factors. After the positive wire is threaded, follow with the negative wire while ensuring it runs parallel to the positive wire but is safeguarded against contact. Correct separation of these wires is pivotal in minimizing risks of short circuits or electrical interference. Proper threading is instrumental in delivering reliable performance and ensuring safety standards are met in solar installations.

6. MAKING CONNECTIONS

Once the wires have been threaded appropriately, the next stage involves making secure connections. Utilizing connectors that are suitable for solar applications is essential. MC4 connectors are a popular choice as they are designed for outdoor use and can be easily snapped together and disconnected when needed.

When connecting the wires, meticulous attention to detail is paramount. Strip the ends of the wires adequately using wire strippers, ensuring precision to avoid damaging the metal inside. Next, insert the stripped end into the connector and crimp it securely. This step ensures a reliable connection that can withstand mechanical stresses. It is important to double-check the polarity of connections; connecting a negative to a positive can cause malfunctioning or damage to the entire system. Therefore, careful connection processes play a critical role in the installation and overall efficiency of the solar system.

7. COMPENSATING FOR ENVIRONMENTAL FACTORS

Environmental considerations play a significant role in solar power installations, especially regarding wire threading and management. Factors such as temperature, humidity, and wear from the elements can impact wiring. For example, high temperatures may cause wires to expand and potentially lead to loosening of connectors over time. Thus, choosing appropriate gauge wires for the anticipated ambient conditions is crucial.

Additionally, installation should consider the potential for physical damage. Running wires through places where they can be exposed to wildlife, branches, or other hazards necessitates protective measures. Utilizing conduits or placing wires underground can help safeguard them against damage. A thorough understanding of environmental factors influencing solar installations can guide better practices for wire threading and overall system reliability, ensuring long-lasting performance.

8. MAINTAINING SOLAR POWER WIRE INTEGRITY

Once the installation process is complete, maintaining the integrity of the solar power wires takes ongoing attention. Regular inspections are crucial, particularly after significant weather events like storms or heavy snowfall. During these assessments, look for signs of wear, frayed insulation, or loose connections. Early detection of issues can prevent more extensive system failures, ensuring sustained energy output.

Moreover, cleaning cables periodically to remove dirt and debris that might insulate wire surfaces is beneficial. Accumulation of grime can lead to inefficiencies, particularly in junction boxes or connectors. In essence, good maintenance practices contribute significantly to the long-term success of a solar power installation, ensuring efficient performance and reducing the need for costly repairs in the future.

FREQUENTLY ASKED INQUIRIES

WHAT KIND OF WIRE DO I NEED FOR SOLAR POWER INSTALLATIONS?

For solar power installations, the preferred wire type is Photovoltaic (PV) wire. PV wires are specifically designed to withstand outdoor conditions, including sunlight exposure, high temperatures, and moisture. These wires also feature a durable jacket material that resists UV damage, ensuring longevity in the elements. When selecting wire, it’s crucial to choose the appropriate gauge based on the length of the run and the current that will be carried. Thicker wires are necessary for longer distances to reduce voltage drop. Furthermore, ensure that the wire is rated for the maximum current output anticipated in the system. For added safety, adherently follow the National Electrical Code (NEC) regulations pertaining to solar installations, emphasizing the importance of using wires specifically designed for solar applications.

HOW DO I KNOW IF MY WIRING IS PROPERLY CONNECTED?

To ascertain if your wiring is connected correctly, follow systematic troubleshooting methods. Upon completion of wiring, one effective way to check connections is by using a multimeter to measure voltage across connections. Ensure that the readings match the expected outputs, verifying that each connection is intact. Furthermore, observe the physical condition of connectors—secure and locked MC4 connectors should not easily pull apart. During the initial test, also monitor the solar system’s performance under load conditions; significant inefficiencies or unusual readings may indicate wiring issues or connections not secured properly. Conducting these checks not only ensures that all wiring is correctly installed but also contributes to the safe performance of the solar power system.

WHAT ARE THE COMMON MISTAKES MADE DURING SOLAR WIRE INSTALLATION?

Several common mistakes can occur during solar wire installation that may severely affect system performance. One major error includes improper wire sizing; using wires that are too small for the current they carry can lead to overheating and potential fire hazards. Another frequent issue arises in miswiring, particularly with positive and negative connections; incorrectly connecting these wires can lead to system failure or damage to the solar panels. Additionally, neglecting to secure connections properly can result in corrosion over time, significantly impacting energy efficiency. Lastly, the failure to adhere to safety standards could result in legal troubles or dangerous conditions. Awareness and preparation can solely mitigate these mistakes, ensuring a successful and safe solar installation.

Achieving an effective solar power wire threading operation hinges on meticulous preparation, adherence to best practices, and ongoing maintenance. By familiarizing oneself with the various components of solar installations, understanding wire types and connections is pivotal for optimal performance. Safety must be prioritized throughout the installation process, ensuring that potential hazards are managed and mitigated. The proper choice of tools simplifies installation efforts and enhances overall reliability, making every aspect from threading to making connections paramount. Additionally, awareness of environmental factors enables better cable management, promoting a seamless and efficient solar installation. Regular maintenance checks post-installation fortify system integrity, guaranteeing long-lasting, trouble-free performance. In essence, threading solar power wires, when executed with careful consideration, not only facilitates energy harnessing but also fosters responsible energy use for the environment. The successful implementation of solar technology contributes significantly to future sustainable energy solutions, and understanding the nuances of wire threading is an essential step towards achieving energy independence and resilience.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-thread-solar-power-wires/