To effectively assess the quality of solar lamp beads, one must consider multiple critical factors. 1. Material composition serves as a primary indicator of longevity and efficiency; 2. Light output should meet specific luminosity standards for effective illumination; 3. Durability and weather resistance ensure functionality over time; 4. Testing methodologies provide insights into performance metrics. Particularly noteworthy is the importance of material composition, as high-quality materials enhance both the lifespan and the effectiveness of the solar lamp. Materials such as ceramic or high-grade plastic are substantial indicators of quality, as they resist wear and tear better than inferior counterparts.

1. MATERIAL COMPOSITION

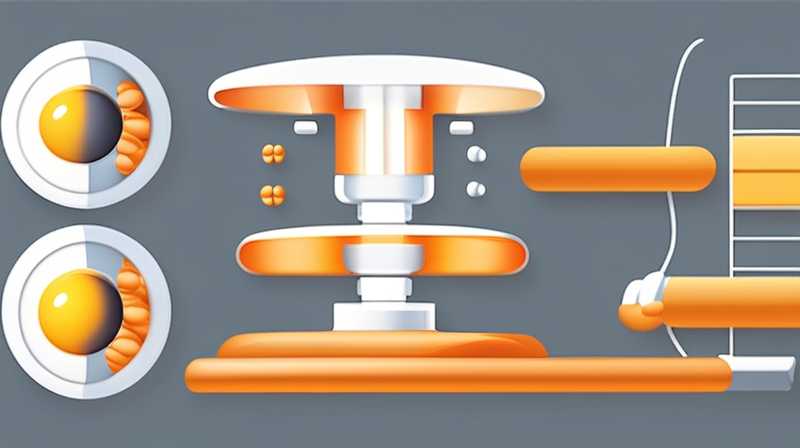

When exploring the realm of solar lamp beads, one must start by examining the material composition used in their construction. High-grade materials play a pivotal role in determining the efficiency and lifespan of these components. Generally, solar lamp beads are manufactured using materials such as silicone, glass, or plastic. Silicone, for example, is lauded for its flexibility and resilience to varying temperatures, which makes it an optimal choice for outdoor applications. In contrast, glass beads tend to offer superior light diffusion, thus producing a more aesthetic lighting effect.

The durability of solar lamp beads directly relates to the manufacturing process employed. Quality through the production phase typically leads to better chemical resistance and lower chances of degradation under UV exposure. The significance of selecting rods made from materials with high UV resistance cannot be overstated. With time, cheaper materials may exhibit brittleness, which compromises both optical performance and structural integrity. Hence, a meticulous evaluation of the materials used is vital for anyone seeking long-lasting solar lamp beads.

2. LIGHT OUTPUT AND EFFICIENCY

As one navigates through various options in solar lamp beads, it becomes critical to scrutinize the light output and overall efficiency of each variant. The luminous efficacy is generally measured in lumens per watt, providing a quantifiable approach to understanding lighting performance. High-quality beads often produce a greater amount of lumens with lesser energy consumption. This aspect becomes essential, as sustainability is paramount, and efficient energy use contributes to minimizing environmental impact.

Another factor to consider is the color temperature of the emitted light. Many consumers prefer a warm glow for specific settings, while others might opt for cooler tones depending on the ambiance desired. Ideally, quality solar lamp beads provide the versatility of adjustable color temperatures, allowing for various applications, whether for functional outdoor lighting or decorative purposes. The testing of lumens produced should ideally occur within controlled conditions to ensure accuracy. Hence, full consideration of these factors is essential to determining the quality of solar lamp beads in terms of light output and energy efficiency.

3. DURABILITY AND WEATHER RESISTANCE

Durability stands out as a crucial element in the evaluation of solar lamp beads. Given that these beads are typically employed in outdoor settings, resilience to weather variations is indispensable. High-quality beads are often designed to withstand extreme temperatures, rainfall, and exposure to sunlight without losing functionality. When assessing durability, one must examine the encapsulation methods utilized during the production process.

An important aspect of durability is IP rating, which denotes Ingress Protection against environmental factors. For instance, an IP65 rating indicates protection against dust and low-pressure water jets. The higher the rating, the better the weather resistance of the beads, making it a significant criterion in quality assessment. Understanding this aspect can lead to informed choices that translate to long-term performance and reduced maintenance costs.

Moreover, the impact resistance of solar lamp beads deserves consideration, particularly in areas prone to harsh weather conditions or potential mechanical damages. Quality beads are designed to withstand impacts without shattering. Therefore, when testing the durability factor, evaluating both the IP rating and resistance to potential physical stressors ensures a more comprehensive understanding of the product’s longevity.

4. TESTING METHODOLOGIES

In scrutinizing the quality of solar lamp beads, employing effective testing methodologies is paramount. Various methods exist to measure performance, and understanding them enables an informed assessment. For instance, photometric testing allows for the simulation and measurement of light distribution patterns as well as light emission efficiency. This method ensures that the beads function optimally within the intended application environment.

Another essential technique is thermal analysis to assess the operational temperature range of the beads under different working conditions. A good thermal profile translates to better efficiency and operational longevity. Furthermore, product reliability testing involves evaluating how these beads perform over prolonged use, assessing essential aspects such as potential light dimming and luminosity output over time.

Lastly, conducting comparative studies through field testing showcases how solar lamp beads perform when subjected to real-world conditions. Sending beads into various environments allows for the collection of data on their efficiency and durability, providing valuable feedback for continuous product improvement. Overall, rigorous testing via various methodologies not only affirms but enhances the quality assurance processes surrounding solar lamp beads.

QUESTIONS AND ANSWERS

WHAT ARE THE COMMON MATERIALS USED IN SOLAR LAMP BEADS?

Solar lamp beads are commonly constructed from materials such as plastic, glass, silicone, and metal. Each of these materials contributes differently to the overall performance and durability of the beads. Plastic is light and relatively inexpensive, making it a popular choice for cost-effective applications. However, it may not offer the same level of UV resistance compared to glass or silicone. Glass beads, while heavier and more fragile, provide superior light diffusion, enhancing the aesthetic appeal when illuminated. Alternatively, silicone beads stand out for their flexibility and robustness, making them capable of withstanding environmental variations.

Moreover, some manufacturers employ metal casings in conjunction with glass or silicone beads to fortify structural integrity. Such combinations result in a comprehensive solution that leads to longer-lasting products. Additionally, the choice of materials corresponds to specific applications; for example, if the primary goal is to enhance diffusion, glass would be preferred, but it may lack in other functional areas such as flexibility and weight.

HOW CAN ONE EFFECTIVELY TEST THE QUALITY OF SOLAR LAMP BEADS?

Effectively testing the quality of solar lamp beads involves evaluating several parameters. Start by assessing the material quality to determine durability and resistance to degradation over time. This includes checking for UV stabilization and thermal properties. Next, conduct luminous efficacy tests to quantify light output per watt consumed, which provides insights into both brightness and energy efficiency.

From a practical standpoint, field testing is invaluable. By placing solar lamp beads in various real-world conditions, one can observe their performance over time, noting any declines in brightness, structural integrity, or functionality. Engaging in comparative analysis with similar products can also shed light on relative quality levels.

Understanding the testing methodologies, such as photometric or thermal analysis, opens the door for deeper insights into performance metrics. Continuous monitoring of these aspects ensures a comprehensive picture of quality, longevity, and functionality, allowing for informed decisions that positively impact the user experience.

WHAT IS THE SIGNIFICANCE OF IP RATING IN SOLAR LAMP BEADS?

IP rating, or Ingress Protection rating, plays a pivotal role in evaluating the weather resistance of solar lamp beads. This metric indicates how well a product can withstand dust and moisture ingress, which is essential for any outdoor lighting solutions. The first digit represents protection against solid objects, while the second digit denotes moisture protection. For example, an IP65 rating signifies complete dust-proofing and protection against low-pressure water jets.

Understanding the importance of these ratings helps consumers make informed purchasing decisions. A higher IP rating usually equates to greater reliability, particularly in unfavorable weather conditions. For those living in regions characterized by heavy rainfall or extreme weather, opting for beads with superior IP ratings becomes comparable to an insurance policy for their outdoor lighting solutions.

Furthermore, the concept of longevity in outdoor applications hinges on how well the product can maintain its performance over time in the face of environmental challenges. Beads with low or no ratings may suffer from a decline in integrity, leading to premature product failure. Therefore, IP rating serves as an indispensable benchmark in determining quality and suitability for varied outdoor applications.

FINAL THOUGHTS

Evaluating solar lamp beads requires a multi-faceted approach that encompasses several dimensions of quality. Sustained interest in renewable energy solutions, particularly solar lighting, calls for meticulous scrutiny of materials and components used in their assembly. A focus on material composition, light output, durability, and testing methodologies highlights critical factors in assessing quality. Understanding these elements ensures optimal selection for both performance and longevity, ultimately resulting in a more sustainable and reliable lighting solution.

The exploration of material composition reveals a profound relationship between the choice of materials and the performance of solar lamp beads. Opting for high-grade substances not only boosts durability but also enhances the aesthetic appeal achieved through various light diffusion techniques. An increased emphasis on light output ensures that consumers receive sufficient illumination, meeting both functional needs and personal preferences.

Furthermore, as outdoor applications come into play, the significance of weather resistance surfaces as an essential criterion. The longevity of solar lamp beads heavily relies upon their ability to withstand environmental adversities. Assessing factors such as IP ratings can greatly influence the effectiveness of these products over time.

Incorporating rigorous testing methodologies into the evaluation process strengthens the assurance of quality. By adopting a hands-on approach through field testing, manufacturers can assess real-world performance metrics, leading to enhancements and refined designs that elevate the user experience.

In a world increasingly leaning towards renewable energy, it becomes indispensable for consumers to remain well-informed and discerning in their choices. Ultimately, the quality of solar lamp beads serves as a touchstone for broader sustainability endeavors, making meticulous testing and evaluation crucial in maintaining efficacy and reliability in the constantly evolving landscape of solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-test-the-quality-of-solar-lamp-beads/