A solenoid valve malfunction in solar energy systems can compromise efficiency and lead to significant operational issues. 1. Observing irregular fluid flow patterns, 2. Conducting electrical tests for continuity, and 3. Assessing the valve’s physical condition for damage or corrosion are paramount. A detailed examination of these aspects can guide an effective diagnosis. One critical point is that irregular fluid flow patterns can manifest as inconsistent water pressure or erratic operation of the solar heating system. This inconsistency often indicates that the valve is either stuck open or closed, contributing to inadequate system performance and potential equipment damage. Monitoring performance regularly can lead to early identification of such issues.

1. UNDERSTANDING THE SOLENOID VALVE’S ROLE

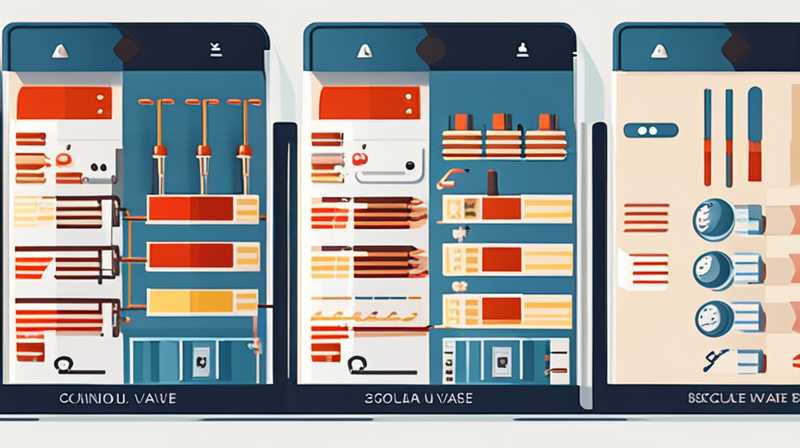

The solenoid valve plays a pivotal part in regulating fluid flow within solar energy systems. These valves utilize electromagnetic coils to manage the open and closed states, enabling precise control over the movement of fluids. Understanding its function is crucial in pinpointing failures. A typical operational scenario involves a shift from electrical energy to mechanical motion, which opens or closes the valve.

Moreover, these valves are often employed in various applications across the solar energy spectrum, including solar water heating and photovoltaic systems. Typically, the solenoid valve operates based on electrical signals that dictate its state, directly influencing the efficiency of the solar system. When evaluating malfunction, proper comprehension of these dynamics holds great significance, as it can expose broader implications for system maintenance, efficiency, and longevity.

2. COMMON SYMPTOMS OF A MALFUNCTIONING SOLENOID VALVE

Recognizing the signs of a failing solenoid valve is the first crucial step in addressing potential issues. One might experience inconsistent flow rates or a complete halt in fluid movement. Such symptoms often indicate a blockage caused by debris or internal wear, leading to significant operational challenges.

In addition to flow irregularities, listen for unusual noises emanating from the valve area. These sounds can help identify a struggle within the valve mechanism itself, whether due to dirt buildup or mechanical failure. With solar energy installations requiring optimal functionality, neglecting these symptoms could lead to long-term performance degradation, emphasizing the importance of regular monitoring and prompt intervention.

3. MECHANICAL INSPECTIONS AND TESTING

To properly diagnose a solenoid valve, consider engaging in a thorough mechanical inspection. Begin by isolating the valve from the broader system. This step ensures that a focused assessment can be conducted without interference from external components. Upon access, pay particular attention to signs of physical damage, such as cracks or corrosion on the housing.

Moving beyond visual assessments, conducting electrical tests is also paramount. Utilizing a multimeter, check for continuity in the solenoid coil. An absence of continuity signals a significant issue, potentially indicating that the coil has burned out or sustained other forms of damage. Diligence in carrying out these tests will enhance the overall reliability of the evaluation, ensuring that every potential issue is addressed.

4. ADVANCED DIAGNOSTIC TECHNIQUES

In circumstances where simple inspections fail to yield clear results, a number of advanced diagnostic techniques may be employed. Thermal imaging, for instance, can unveil hot and cold spots, which might indicate malfunctioning areas within the valve or connected components. This method allows for a more nuanced understanding of operational failures.

Additionally, flow rate testing can deliver invaluable insights into the performance of the solenoid valve. By comparing the measured flow rate against the required specifications, one can identify notable discrepancies that warrant further investigation. Through such methodologies, operators can gain access to comprehensive data, arming them with the knowledge needed to inform repair or replacement decisions.

5. REPLACEMENT CONSIDERATIONS

When addressing solenoid valve failure, determining whether to repair or replace the unit becomes vital. Cost assessments and availability of replacement parts will influence this decision. In many instances, purchasing a new solenoid valve may be more economical than engaging in repairs, especially if the existing unit is older or has sustained significant wear.

Further, it is essential to consider compatibility. Replacement valves should align with the specifications of the existing system to ensure seamless integration. Moreover, opting for high-quality components will promote greater longevity, reducing the need for future replacements. As such, diligent research into quality assurance and supplier reputation becomes instrumental in achieving a satisfactory resolution.

6. MAINTENANCE STRATEGIES TO AVOID FAILURE

Active maintenance serves as a proactive measure to prevent solenoid valve failure in solar energy systems. Regular cleaning of the valve equipped with a filter can help prevent debris accumulation, which often leads to performance issues. Establish a routine inspection schedule, enabling early detection of any irregularities before they evolve into major complications.

Other strategies involve consistently monitoring system performance metrics, such as fluid flow rates and temperature. These metrics can highlight discrepancies that signal potential valve problems before they escalate. Incorporating such preventive strategies into system management guarantees prolonged operational effectiveness, minimizing downtime in solar energy practices.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I CHECK MY SOLENOID VALVE?

Conducting regular checks on your solenoid valve is essential to ensuring optimal performance. It is prudent to perform inspections at least bi-annually, ideally coinciding with seasonal transitions when solar energy usage fluctuates most. This approach allows for timely detection of any irregularities, ensuring continuous and efficient operation.

During inspections, examine not only the valve’s physical condition but also its functionality within the system. Listening for unusual sounds and observing the flow rate can reveal early warning signs of potential issues. Implementing a proactive inspection regimen can extend the lifespan of your solenoid valve, ultimately enhancing the longevity and reliability of your entire solar energy system.

WHAT SIGNS INDICATE A MALFUNCTIONING SOLENOID VALVE?

The most common signs of solenoid valve malfunction encompass inconsistent fluid flow and unusual noises. Citizens often experience erratic pressure or leakages, which can compromise the efficiency of solar energy systems. It’s essential to remain vigilant and attentive to these symptoms, as neglect may lead to more severe systemic failures.

Visual inspections can reveal physical damage, such as corrosion or fractures. Employing diagnostic tests like electrical continuity checks can further substantiate suspicions of malfunction. The earlier these indicators are recognized, the more effective prompting timely intervention can lead to resolution, ensuring continuous operation without detrimental downtime.

CAN I REPAIR A SOLENOID VALVE MYSELF?

While some individuals possess the technical acumen to undertake repairs, evaluating the complexity of the malfunctions is key. For minor issues, such as replacing a faulty coil or cleaning debris from the valve, self-repair is entirely feasible. However, more complicated issues — such as significant internal component failure — often require professional intervention.

Prior to attempting self-repair, gather all necessary tools and materials, along with comprehensive guides or manuals specific to the valve model. If uncertainties arise during the process, consulting with a qualified technician may provide assurances that repairs are conducted safely and effectively, preserving the functionality of your solar energy system.

An effective understanding of solenoid valve operation and malfunction detection is crucial for maintaining optimal performance in solar energy systems. Regular inspection, timely intervention, and informed diagnosis enhance system reliability, minimize downtime, and ultimately optimize energy efficiency. Implementing strict maintenance schedules, coupled with robust diagnostic methods, proves essential in extending the lifespan of these components. By addressing potential issues promptly and accurately, operators can safeguard the performance of their solar systems, paving the way for sustainable energy solutions that continue to thrive.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-tell-if-the-solenoid-valve-is-broken-in-solar-energy/