To effectively split solar photovoltaic panels requires precise techniques tailored to specific panel types and configurations. 1. Understanding Panel Types, 2. Tools Required, 3. Safety Precautions, 4. Step-by-Step Process. It is crucial to comprehend the types of panels involved, as different photovoltaic materials (like monocrystalline or polycrystalline) have unique characteristics that may affect the method of separation. The safety measures taken during this operation are paramount to prevent electrical hazards, potential injury, and panel damage. Using the appropriate equipment and ensuring proper working conditions enhances the overall efficiency and safety of the task at hand.

1. UNDERSTANDING PANEL TYPES

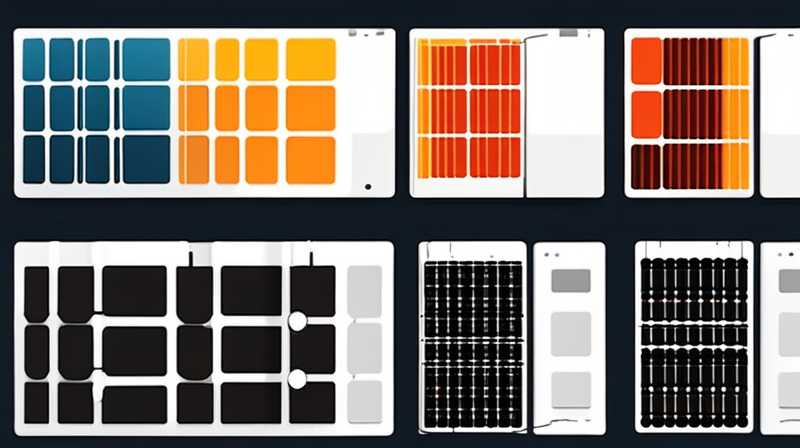

When contemplating the division of solar photovoltaic panels, the initial factor involves a comprehensive understanding of the various types available in the market. Monocrystalline panels are created from a single crystal structure, known for their high efficiency and longevity, while polycrystalline panels consist of multiple crystals, generally at a lower cost and efficiency. Thin-film panels represent another alternative, made from layers of photovoltaic material that can be deposited onto various substrates.

Each panel type has unique characteristics that influence the approach to splitting. Monocrystalline panels are usually preferred due to their high energy output and efficiency, but they are also thinner and more susceptible to cracking during the splitting process. Contrarily, polycrystalline panels may be less efficient but can be easier to work with due to their sturdiness. Thus, understanding materials and their intrinsic properties is critical before proceeding with any disassembly.

In addition to considerations surrounding efficiency and cost, there exists a notable difference in the manufacturers and warranties associated with each panel type. Some manufacturers offer warranties that extend beyond 25 years for monocrystalline panels, whereas polycrystalline panels might come with shorter warranty periods. Understanding these distinctions will aid in making informed decisions on whether splitting is a feasible option and if repairs or replacements are warranted.

2. TOOLS REQUIRED

Acquiring the appropriate tools and equipment is crucial for successfully dividing solar panels. A well-equipped toolkit should include a multimeter for measuring voltage, amperage, and resistance to ensure that the panel is safely powered down; a voltage tester to confirm that no current is present in the system; and safety glasses and gloves to protect oneself during the operation.

Moreover, additional tools such as a saw or cutter specifically designed for photovoltaic materials are recommended. These specialized tools can make precise cuts without damaging the photosensitive cells within the panels. A replacement adhesive for reattaching any sections after splitting also proves valuable, as it helps maintain the panels’ structural integrity after alteration.

In addition to manual tools, it is advisable to have access to safety equipment such as a first aid kit, fire extinguisher, and appropriate personal protective equipment (PPE). In a situation where electrical hazards are present, quick access to necessary safety gear will be essential for addressing any unforeseen incidents. Furthermore, optimizing the workspace by ensuring a clean and organized area minimizes the risk of accidents and enhances operational efficiency during the splitting process.

3. SAFETY PRECAUTIONS

Implementing rigorous safety measures is paramount when undertaking a project involving the splitting of solar photovoltaic panels. Before initiating any work, it is essential to disconnect the panels from their power source to mitigate the risk of electric shock. Ensure that the area is well-ventilated and free from any flammable materials, reducing the potential for accidents.

Equally important is the use of personal protective gear, which should include insulated gloves, safety goggles, and masks. Isolating oneself from electrical currents and protecting the eyes from debris during the cutting process can prevent injuries. It is prudent to inspect all tools before use, ensuring they are in good working condition.

Moreover, it is advisable to work in pairs or have someone present to assist should an emergency arise. A second pair of hands can provide immediate assistance in case of an accident, ensuring that injuries do not go unaddressed during critical moments. Keeping a mobile phone or communication device nearby can also facilitate quick access to help if necessary.

Lastly, staying informed about the risks associated with the specific panel type being handled is crucial. Familiarizing oneself with the manufacturer’s guidelines and recommended safety protocols will provide an additional layer of preparedness. Adhering to these practices will not only safeguard the individual but will also enhance the chance of successfully completing the task without complications.

4. STEP-BY-STEP PROCESS

Beginning the actual splitting process requires careful planning and execution. First, ensure that all required tools are at hand and that safety precautions are strictly followed. Before any cutting occurs, it is vital to perform an electrical safety check of the panels. This entails confirming they are not receiving any power and using a multimeter or voltage tester to verify.

Once safety has been assured, the next phase involves marking the intended cut lines on the panel. Utilizing a straight edge or measuring tape can help maintain accuracy and precision. It is crucial to develop a well-defined plan outlining the sections to be separated, ensuring clarity throughout the procedure.

When ready to commence cutting, employ a suitable saw or cutter, making deliberate and controlled motions. Starting at one corner and working methodically helps prevent excessive force which could compromise the integrity of the remaining panel. Caution is vital when navigating around sensitive photovoltaic cells as unnecessary damage could result in severe efficiency loss.

Once the panel is split, the edges may require sanding or smoothing to ensure there are no sharp or jagged areas that could present future hazards. Applying adhesive to reattach any necessary components is often necessary to maintain structural integrity. After all modifications are complete, conduct a thorough inspection and, if possible, retest the electrical integrity before reintroducing the panels to their intended solar power system.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON REASONS FOR SPLITTING SOLAR PANELS?

Splitting solar photovoltaic panels can arise from various circumstances. One of the most prevalent reasons is damage, where sections of a panel may have become cracked or non-functional, necessitating repair or replacement. Smaller segments can be salvaged from a larger, damaged panel, allowing for continued use in producing energy.

Another reason often involves optimization for specific installations. In some cases, smaller panel sizes better fit unique spaces or specific mounts, enabling more efficient energy harvesting in non-standard settings. Altering panel sizes can also assist in achieving a desired output when integrating them with existing systems.

Lastly, cost considerations may provoke the decision to split panels. Rather than purchasing new, higher-efficiency panels outright, adjusting existing ones allows users to optimize their investment while potentially extending their usability. This adaptability enables individuals to address their unique energy needs without incurring significant expenses.

HOW CAN I DETERMINE IF MY PANELS NEED SPLITTING OR REPLACEMENT?

In determining whether panels require splitting or full replacement, a thorough assessment is necessary. Start by examining the physical condition of the panels. Look for signs of cracking, discoloration, or non-functionality, such as consistently low output levels, which may indicate the need for repair. Using a multimeter, you can measure the voltage output to compare against specifications for your panels.

Furthermore, assessing the performance history of the solar system will aid in making an informed choice. If the panels have experienced consistent performance degradation or damage from environmental factors like storms or hail, it may render the panels less efficient over time. A professional inspection can offer invaluable insights into whether the issue lies within a single panel or if overall system failure is occurring.

When evaluating these factors, consider the age and warranty status of the panels. If they are nearing the end of their warranty period and showing signs of decline, it might be prudent to invest in newer technology rather than attempting repairs on older models whose efficiency cannot be guaranteed.

WHAT IS THE POTENTIAL IMPACT ON EFFICIENCY WHEN SPLITTING PANELS?

The impact on efficiency when splitting solar panels can vary significantly based on the method employed and the existing condition of the panels. If performed correctly, splitting panels can allow for continued energy production from otherwise compromised units, leading to minimal if any, efficiency losses. However, improper execution or excessive damage during the process may severely hinder output capacity.

The potential alteration in efficiency will largely depend on the number of cells remaining intact post-splitting. As each solar cell contributes to the panel’s overall energy conversion effectiveness, maintaining as many functional cells as feasible will help ensure energy output remains at a high level. If significant portions of the panel are lost, efficiency will decline proportionately with the number of operational cells left.

Furthermore, the quality of repair conducted post-splitting can also influence efficiency outcomes. Utilizing appropriate adhesives and sealing techniques will mitigate the risk of environmental ingress and damage. This careful approach can help maintain the panel’s integrity and performance in the long term.

In performing the task of splitting solar photovoltaic panels, diligence and attentiveness are vital. Understanding the various panel types shapes the strategy employed, while having the right tools and safety measures in place protects against potential hazards. A meticulous approach ensures that panels can be altered to extend their operational life without incurring extensive losses in efficiency. Addressing why panels might need splitting can help inform best practices, while careful assessment throughout the process aids in decision-making related to repairs versus replacements. Clearly, the undertaking is replete with critical considerations that demand careful attention and expertise in photovoltaic technology to navigate successfully. Ultimately, skilled handling not only safeguards personal safety but also fosters a sustainable energy future through optimized usage of existing resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-split-solar-photovoltaic-panels/