Sure! Here’s a comprehensive article on how to solve the solar overflow valve issue.

1. The issue regarding solar overflow valves can be addressed effectively by following three critical aspects: 1) Understanding the mechanism of overflow valves, 2) Identifying the common problems associated with them, 3) Implementing the necessary repair techniques for optimal functionality. One core element that requires attention is the understanding of the overflow valve’s operational mechanics, as this knowledge facilitates an in-depth grasp of potential issues and appropriate remedial actions. By integrating this understanding with practical repair methods, one can ensure prolonged efficiency and reliability of solar energy systems.

1. UNDERSTANDING SOLAR OVERFLOW VALVES

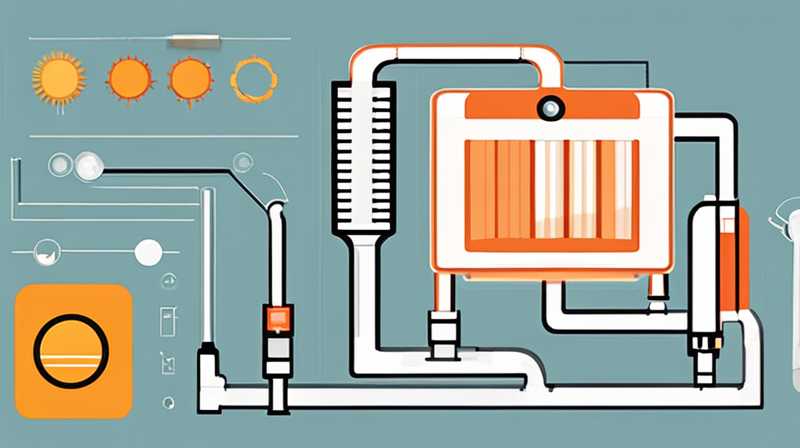

Solar overflow valves play a crucial role in regulating the pressure and fluid flow within a solar heating system. These devices are designed to prevent excessive pressure buildup by diverting extra fluid, usually in the form of solar heat transfer fluid, back to the storage tank or bypassing sections of the system. When these valves function correctly, they ensure that the solar system operates efficiently and safely, delivering the necessary heat to the desired applications.

The mechanism behind the overflow valve involves a combination of thermodynamic principles and physical components. Typically, these valves operate using a pressure-sensitive spring mechanism that opens or closes based on the fluid’s pressure. As the temperature rises, resulting in increased fluid expansion, the valve reacts by opening, allowing the excess fluid to escape. This safeguards the system from potential damage, such as burst pipes or equipment failure, which could result from excessive pressure. Therefore, a detailed understanding of this functioning is essential for diagnosing issues effectively.

1.1 IMPORTANCE OF MAINTAINING FUNCTIONALITY

Maintaining the functionality of solar overflow valves is paramount for any solar heating system. When the valve malfunctions, it can result in several operational issues, including reduced efficiency and potential system failures. An overflow valve failure may lead to overflowing fluid, loss of heated water, or even considerable damage to the solar panels or storage tanks.

Moreover, routine inspections and preventive maintenance can significantly enhance the longevity of the entire solar heating system, thus protecting the initial investment. Recognizing warning signs, such as abnormal noises, leaks, or inconsistent temperature readings, can enable quicker responses, reducing the risk of extensive damage. Understanding the valve’s significance will empower system owners to undertake regular checks, ensuring uninterrupted functionality and enhanced performance.

2. COMMON PROBLEMS WITH SOLAR OVERFLOW VALVES

Identifying prevalent issues with solar overflow valves is essential for maintaining system integrity and performance. Problems can arise due to various reasons, including wear and tear, external environmental factors, and incorrect installation or configuration. Recognizing these issues can streamline the troubleshooting process.

2.1 LEAKAGE AND SEAL FAILURE

One of the most common problems encountered in solar overflow valves is leakage, often resulting from seal deterioration. The seals are designed to create a tight barrier that prevents fluid from escaping. Over time, exposure to harsh environmental conditions, thermal cycles, and aggressive fluids can lead to the breakdown of these seals. Leakage not only hinders the efficiency of the system but can also cause corrosion in adjacent components due to prolonged exposure to the fluid.

To mitigate such issues, regular inspections of the seals are advised, with replacements carried out when degradation is observed. Utilizing high-quality materials that withstand extreme temperatures and environmental stress can prolong seal lifespan, consequently improving overall system performance. Implementing a proactive approach to seal management is critical in preventing significant operational disruptions.

2.2 BLOCKAGES IN THE VALVE MECHANISM

Blockages within the valve mechanism can severely impair its functioning. Accumulation of debris, sediments, or even biofouling can prevent the valve from operating smoothly, leading to pressure imbalances within the system. This can result in either excessive fluid flow or insufficient fluid movement, which directly affects the efficiency of heat transfer processes.

To resolve blockage issues, routine cleaning and maintenance are necessary. Implementing filter systems to capture particulates prior to entering the valve can significantly reduce the likelihood of blockages. Additionally, smart design choices that promote free flow and easy maintenance access can facilitate timely interventions to clear obstructions, ultimately improving system efficiency.

3. SOLVING SOLAR OVERFLOW VALVE ISSUES

Addressing complications with solar overflow valves requires a structured approach that includes diagnosis, repair, and preventive measures. Engaging with the problem methodically ensures that potential repercussions are minimized while promoting sustained functionality.

3.1 DIAGNOSIS AND ASSESSMENT

The initial step in resolving valve issues involves a thorough diagnosis and assessment. This includes conducting visual inspections to identify external signs of wear, such as cracks, leaks, or rust. Employing pressure gauges and temperature sensors can provide quantitative data, allowing for assessment of the valve’s operational status.

Once the issues have been identified, it’s vital to document the findings methodically. Take note of the specifics, as this information will be instrumental in implementing effective solutions. Engaging with industry best practices, or consulting reputable experts, can further enhance the assessment process, resulting in targeted interventions.

3.2 REPAIR AND REPLACEMENT

Depending on the diagnosis, repairs may involve replacing seals, clearing blockages, or, in severe cases, replacing the entire valve. For minor issues, such as seal replacement, ensure to choose high-quality components that meet or exceed the manufacturer’s specifications. This choice is crucial in ensuring the repair’s longevity and effectiveness.

In situations where a valve has sustained significant damage, consider replacing it entirely. This can be a more economical solution over time, particularly for valves suffering from extensive wear. Installation should follow manufacturer guidelines closely to mitigate risks associated with improper fitting. Engaging in a methodical approach in both repair and replacement guarantees the effective restoration of functionality to the solar overflow valve.

4. PREVENTIVE MEASURES AND BEST PRACTICES

Implementing preventive measures is essential in ensuring that solar overflow valves continue to operate effectively over the long term. By adopting systematic maintenance practices and integrating technology into monitoring systems, one can significantly extend the lifespan of these critical components.

4.1 REGULAR INSPECTIONS AND MAINTENANCE

Routine inspections of solar overflow valves are highly recommended. These inspections should include checks for leaks, structural integrity, and operational performance under various conditions. Documenting findings from these inspections allows for trend analysis, providing insights into potential future failures before they happen.

Additionally, a structured maintenance schedule ensures that all aspects of the overflow system are addressed. Consider factors such as seasonal weather changes, which can impact systems differently. Emphasizing regular maintenance can mitigate risks and enhance overall system efficiency, facilitating optimal service delivery.

4.2 IMPLEMENTING AUTOMATED SENSING TECHNOLOGIES

The incorporation of automated sensing technologies can significantly enhance the monitoring of solar overflow valves. Modern sensors designed to measure pressure and temperature variations in real-time can alert system operators to potential issues before they escalate. These technologies can serve as an early warning system, allowing for proactive maintenance rather than reactive measures.

Integrating advanced data analytics can further enhance these practices, leading to customized maintenance schedules or predictive maintenance strategies. Leveraging technology not only improves efficiency but also allows for strategic resource allocation, ensuring that operations remain seamless.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR OVERFLOW VALVE?

A solar overflow valve is a critical component in solar heating systems that regulates fluid pressure and flow. Its primary function is to prevent excessive pressure buildup by diverting extra fluid back to the storage tank or bypassing certain sections of the system. The valve operates based on pressure-sensitive mechanics, opening when pressure exceeds safe limits. Ensuring its proper functionality is essential to maintain the efficiency of solar systems and to safeguard against potential damage caused by excess pressure. Regular maintenance and timely inspections are pivotal to ensuring that the valve continues to perform optimally, thus protecting the solar heating system as a whole.

HOW DO YOU KNOW IF YOUR SOLAR OVERFLOW VALVE IS MALFUNCTIONING?

Indications of a malfunctioning solar overflow valve can manifest in several ways. Common symptoms include visible leaks around the valve area, unusual noises during operation, or fluctuations in system pressure readings. Additionally, if the solar heating system fails to maintain optimal temperatures or if there are sudden drops in fluid flow, these too can signify underlying issues with the overflow valve. Conducting regular inspections and monitoring performance metrics can help identify these symptoms early on. Timely intervention is essential in addressing any identified problems to ensure that the solar heating system operates efficiently and reliably.

WHAT ARE THE COSTS ASSOCIATED WITH REPLACING A SOLAR OVERFLOW VALVE?

The costs related to replacing a solar overflow valve can vary significantly based on several factors. These factors include the specific type and brand of the valve, labor costs, and whether any additional repairs or modifications are necessary during the replacement process. Generally, a high-quality valve can range from $100 to $500, excluding installation fees. Labor costs can add another $50 to $150, depending on the complexity of the job and local rates. Therefore, a comprehensive budget should consider both material and labor expenses to ensure effective planning for replacement activities. Engaging multiple contractors for estimates can provide a clearer picture of potential costs, allowing for informed decision-making.

The effective resolution of solar overflow valve issues is crucial for maintaining the efficiency and longevity of solar heating systems. A thorough understanding of the valve’s operational principles, combined with an awareness of common problems, allows for timely diagnosis and effective repairs. Implementing a structured approach to maintenance can significantly reduce the risks associated with valve malfunction, ensuring prolonged reliability in solar energy systems. Regular inspections, the incorporation of advanced monitoring technologies, and adherence to best practices are critical in sustaining optimal functionality. By prioritizing these aspects, system owners can safeguard their investments and enhance the overall performance of their solar heating systems. Engaging with experts when challenges arise further implies a proactive stance towards managing potential complications. Ultimately, the fusion of knowledge, careful monitoring, and routine maintenance can lead to efficient solar energy exploitation, maximizing benefits while minimizing risks associated with overflow valve management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-solve-the-solar-overflow-valve/