1. The issue of solar tubes regularly experiencing explosions can be addressed through careful consideration of material quality, installation techniques, and maintenance processes. Additionally, understanding the thermal dynamics, pressure management, and environmental factors at play is crucial. Of particular importance is examining the role of thermal expansion and contraction in these incidents, as improper handling of these elements can lead to catastrophic failures. Materials that are rated for high temperatures and pressures, along with comprehensive installation guidelines, are pivotal to mitigating risks associated with solar tubes.

1. UNDERSTANDING SOLAR TUBES

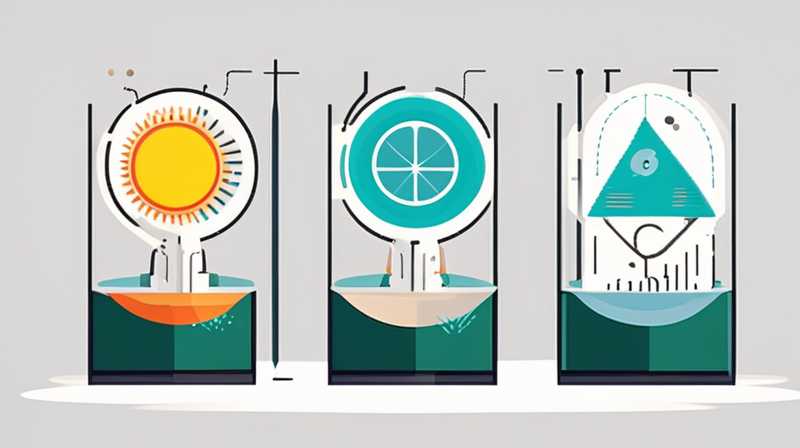

Solar tubes, often known as solar collectors or solar vacuum tubes, are designed to harness solar energy for heating purposes. They consist of glass tubes that contain a vacuum, which significantly enhances their thermal efficiency. However, these devices are not without their shortcomings. One of the most alarming issues they face is the tendency to explode under certain conditions. Understanding the mechanics behind these tubes can provide valuable insights into preventing such failures.

Thermal dynamics play an integral role in the performance of solar tubes. When exposed to direct sunlight, the internal temperature of the tubes can skyrocket. The heat exchange process, aimed at converting solar energy into useful heat, can inadvertently lead to dangerous pressure build-up. If the tubes are not equipped to cope with these changes, an explosion may occur, resulting in both property damage and personal injury.

Another critical factor lies in the material composition of the tubes themselves. High-quality glass and insulation materials are essential for maintaining the integrity of solar tubes. Manufacturers must adhere to strict guidelines to minimize risks. Thus, an understanding of the material’s thermal resistance and pressure tolerance is vital for maintaining optimal performance.

2. MATERIAL QUALITY

The quality of materials used in solar tubes is fundamental in ensuring their safety and longevity. Different materials possess varying thermal properties, which can significantly impact a tube’s ability to withstand extreme heat. Evaluating these properties is crucial for installation and performance.

High-quality glass is paramount for solar tubes. The glass must be tempered or treated to withstand high temperatures and sudden thermal shocks. If the glass is of subpar quality, it could fracture under excessive heat, leading to an explosive failure. As such, consumers and installers should verify the certifications and quality standards of the materials used.

Besides glass, the insulation materials within the tubes also require careful scrutiny. These insulations must maintain their structural integrity while resisting the thermal expansion caused by fluctuating temperatures. Substandard insulation can deteriorate over time, compromising the system’s efficiency and safety. Investing in proper material ensures not only efficacy in energy harnessing but also enhances the safety and lifespan of the solar systems.

3. INSTALLATION TECHNIQUES

Proper installation techniques cannot be overstated when considering the safe operation of solar tubes. Misalignment or incorrect installation can lead to uneven heat distribution, resulting in certain sections experiencing higher temperatures than others. Such discrepancies can lead to pressure differentials that may compromise the tube’s integrity.

Level and secure installation allows for an even distribution of solar energy. It is also essential to ensure that the tubes are installed at the correct angle to maximize exposure to sunlight while minimizing the risk of overheating. Experts recommend conducting thorough surficial assessments to acquire the best installation site, considering elements such as surrounding structures and vegetation that may obstruct sunlight.

In addition to positioning, proper sealants and fittings must be utilized. Inadequate seals can lead to air infiltration, allowing moisture to enter the system. This moisture can not only cause corrosion but also generate steam, leading to pressure build-up and potential explosions. Professionals must employ high-quality sealing methods and materials when fitting the tubes, ensuring that every joint is secure and leak-free.

4. MAINTENANCE PROCESSES

Routine maintenance plays a vital role in extending the lifespan and ensuring the safety of solar tubes. Ignoring preventive measures can lead to unforeseen consequences, including explosions. Regular inspections should focus on identifying signs of wear and tear, such as cracks in the glass or degradation of insulation material.

Cleaning solar tubes is another essential maintenance task. Dirt and debris can accumulate over time, blocking sunlight and reducing efficiency. Moreover, contaminants may lead to localized heating issues. Thus, applying appropriate cleaning solutions and procedures becomes pivotal to maintaining the tubes’ performance and safety.

Pressure monitoring systems should also be installed as part of a maintenance plan. These systems can provide real-time data on the internal pressure of the tubes, warning users of potential danger. If abnormalities in pressure are detected, immediate action can be taken before a disaster occurs. By undertaking these maintenance measures, one can significantly mitigate the risks associated with solar tubes.

5. THERMAL EXPANSION AND CONTRACTION

A critical aspect of solar tube functionality is understanding thermal expansion and contraction. The principle of thermal expansion dictates that materials increase in size when heated and contract when cooled. This behavior can be a double-edged sword. On one hand, it is essential for the tubes to be designed to accommodate this movement, thus preventing stress concentrations that can lead to fractures. On the other hand, if the tubes experience rapid temperature fluctuations, this rapid change can induce too much internal stress, potentially culminating in an explosion.

Utilization of flexible joint materials is one strategy to address these issues effectively. These materials can absorb some of the movements caused by thermal changes, therefore limiting the stress on the tubes. The flexibility of these joints ensures that discrepancies in temperature do not translate into significant issues, thereby enhancing safety.

It is equally important to educate eotechnicians and users about the significance of temperature monitoring. Adopting advanced sensors capable of tracking real-time temperature variations can provide critical information about the conditions under which solar tubes operate. This data can serve as a proactive measure, allowing users to respond to temperature changes before they result in hazardous situations.

6. ENVIRONMENTAL IMPACTS

Environmental factors significantly influence the performance and durability of solar tubes. Weather conditions, such as extreme temperatures, high winds, or hail storms, can adversely affect their structural integrity. It is imperative to evaluate the installation environment meticulously, ensuring adequate protection strategies are implemented.

Location selection is crucial for the efficacy of solar tubes. Tubes installed in areas with prolonged exposure to elements may be prone to damage. Therefore, installing protective covers or selecting locations that shield the tubes from harsh weather can prolong their lifespan and functionality.

Additionally, climate change leads to unpredictable weather patterns that may increase the frequency and intensity of extreme weather events. Users must be aware of their geographical location’s climate trends and adapt their installation and maintenance strategies accordingly. Such foresight can prevent potential disasters that stem from environmental neglect.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MOST COMMON CAUSES OF SOLAR TUBE EXPLOSIONS?

The primary reasons behind solar tube explosions often include heat-generated pressure, improper installation, and degraded materials. When the internal temperature of the tubes exceeds safe limits, it can lead to an increase in pressure that ultimately results in ruptures or explosions. Additionally, installation errors, such as misalignment, can create areas of uneven heat distribution. If these factors are exacerbated by the use of low-quality materials, the risk of failure significantly increases. Regular inspections and proactive maintenance can help mitigate these risks. It’s crucial to ensure that high-quality glass, secure seals, and proper fitting techniques are applied to prevent accidents.

HOW CAN REGULAR MAINTENANCE PREVENT EXPLOSIONS IN SOLAR TUBES?

Consistent maintenance can identify early warning signs of potential issues, aiding in preventing catastrophic failures. Key maintenance tasks include routinely examining for cracks, performing thorough cleaning to ensure maximum sunlight absorption, and checking seals for integrity. By utilizing pressure monitoring systems, one can receive alerts about any abnormal pressure build-up within the tubes. These precautions enhance the longevity of solar tubes and significantly reduce the chances of explosions due to neglect. By fostering a maintenance culture, users can enjoy optimal performance while prioritizing safety.

WHAT ARE THE BENEFITS OF HIGH-QUALITY MATERIALS IN SOLAR TUBE CONSTRUCTION?

Investing in high-quality materials yields numerous advantages for solar tube systems. These materials exhibit superior thermal resistance and pressure tolerance, significantly reducing the likelihood of failure. High-quality glass is less prone to fracturing under thermal stresses, while durable insulation prevents heat loss and maintains optimal efficiency. Utilizing reputable manufacturers who adhere to stringent quality control measures ensures that the products function adequately under varying conditions. By selecting superior components, users not only safeguard their systems but also promote sustainability and long-term returns on investment.

In summary, addressing the recurrent issue of solar tube explosions necessitates a multifaceted approach encompassing the selection of superior materials, meticulous installation practices, and diligent maintenance protocols. By prioritizing these aspects, individuals and organizations can significantly mitigate risks associated with solar tube failures. Understanding the intricate behavior of thermal dynamics and implementing proactive strategies like temperature monitoring and pressure management can further enhance safety measures. Ultimately, investing effort in these areas yields substantial benefits in terms of safety, longevity, and performance, ensuring that solar tubes function optimize ly while harnessing the sun’s energy efficiently. Embracing a comprehensive approach will not only avert potential disasters but also foster a sustainable future for solar energy systems, encouraging their adoption and utilization across diverse environments.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-solve-the-problem-of-solar-tubes-always-exploding/