A comprehensive guide on how to solder solar lamp batteries involves several critical steps: 1. Gather necessary tools and components, 2. Disconnect old batteries from the lamp, 3. Prepare new batteries for soldering, 4. Ensure safe soldering techniques are utilized, 5. Reconnect the solar lamp and test functionality. Each of these steps plays a crucial role in successfully replacing solar lamp batteries, ensuring optimized performance.

1. GATHERING NECESSARY TOOLS AND COMPONENTS

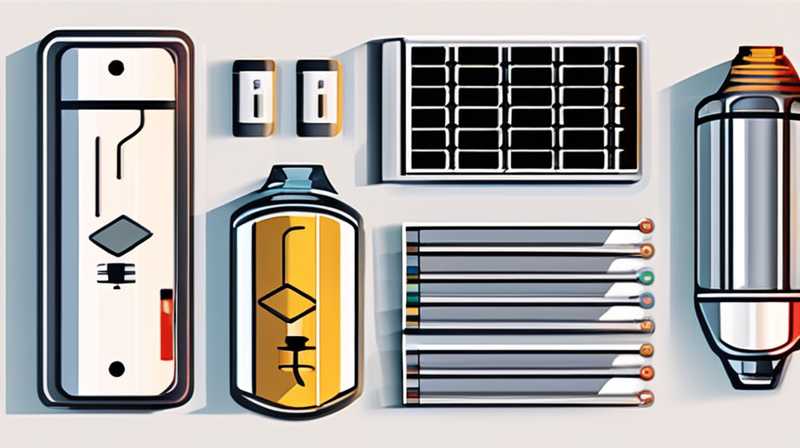

Before embarking on the journey of soldering solar lamp batteries, essential materials and instruments must be gathered. Crucial tools include a soldering iron, solder wire, and safety goggles. A soldering iron is a heat tool that melts solder, a metal alloy, allowing two electrical components to join together when cooled. Safety goggles are vital as they protect the eyes from sparks and molten solder. Moreover, obtaining heat-resistant mats or surfaces to work on can prevent accidental damage or burns.

In addition to those tools, new batteries compatible with the specific solar lamp model are necessary. It is essential to ensure that the batteries have adequate voltage and are rechargeable, as solar lamps typically use rechargeable batteries. Understanding the specifications of the batteries will enhance the overall efficiency. In cases where a solar lamp utilizes different battery types, consulting the product manual becomes imperative to ascertain compatibility.

2. DISCONNECT OLD BATTERIES FROM THE LAMP

Once the required tools and batteries are assembled, the next pivotal step involves safely disconnecting the old batteries from the solar lamp. Begin by identifying the battery compartment, usually located beneath the lamp’s cover. Ensure that the solar lamp has been turned off or no longer exposed to sunlight before proceeding. This precaution prevents any electric shock since solar-powered devices may still hold a charge.

Upon locating the battery compartment, carefully remove old batteries. Most commonly, batteries are secured in place with clips or soldered connections. If they are soldered, a careful application of heat from the soldering iron will be necessary to melt the solder and release the batteries. During this step, exercising caution and ensuring the work area is clean and organized will prevent any accidents and allow for efficient work.

3. PREPARING NEW BATTERIES FOR SOLDERING

After successfully removing the old batteries, the new batteries require preparation for soldering. Ensure that the new batteries are clean and free from oxidation on the terminals. Any debris or corrosion can impede the flow of electricity and lead to device failure. Using a soft cloth or a specialized cleaning solution can restore the necessary conductivity to the terminals, promoting a reliable and secure connection.

Additionally, cutting wires to the appropriate length is crucial before soldering. Lengthy wires can create clutter and increase resistance within the circuit, reducing the efficiency of the solar lamp. Conversely, wires that are too short may create tension during reconnections or even damage the terminals. Knowing how much wire to leave leads to improved electrical flow and longevity of the solar lamp.

4. ENSURING SAFE SOLDERING TECHNIQUES

Soldering involves the application of heat, which can pose risks if not conducted safely. Prioritize using a soldering iron with an ergonomic handle and a stand for stability. This ensures control over the device, reducing the likelihood of burns or accidental contact with other components. Always keep the soldering iron powered off when not in use.

Equally essential is the use of proper solder wire. Lead-free solder is recommended for any application involving batteries. This minimizes the risk of toxic exposure while ensuring effective connections. When soldering, apply just enough solder for a solid connection but avoid overdoing it, as excess solder could lead to shorts or connection issues. Thorough practice of these techniques significantly enhances the quality of the soldered joints.

5. RECONNECTING THE SOLAR LAMP AND TESTING FUNCTIONALITY

Having successfully soldered the new batteries, the last stage includes reconnecting everything and ensuring device functionality. Reinstall the batteries into the compartment, ensuring correct polarity alignment. Batteries typically have a positive (+) and negative (-) terminal. Incorrect positioning can lead to malfunction and potentially damage the lamp.

Once the batteries are aligned and secured, cover the panel and locate the power switch. Activate the solar lamp while placing it under sunlight to commence charging. Give the lamp some time to charge adequately. On testing, observe if the lamp illuminates as intended. If it fails to light up, recheck battery placement, connections, and soldering quality for any errors. Keeping detailed notes throughout the process can help identify issues quickly.

FREQUENTLY ASKED QUESTIONS

HOW CAN I DETERMINE IF MY SOLAR LAMP BATTERIES NEED REPLACEMENT?

Solar lamp batteries typically show signs of performance decline over time. Indicators include diminished brightness, short operational duration, or the lamp failing to light altogether. To determine if the issue lies within the batteries, perform a visual inspection. Look for any swelling, leakage, or corrosion around battery terminals, as these often signal substantial degradation. It is advisable to conduct a replacement if any of these signs become apparent, particularly if the usual charging routine does not restore functionality. Also, consult the operating manual for specific timelines or recommendations on battery replacements based on usage.

WHAT TYPE OF SOLDER SHOULD I USE FOR SOLAR BATTERIES?

For soldering solar panel batteries, using a lead-free solder is highly recommended. Solder composed of tin, copper, or silver provides a reliable and safe means of connection without introducing harmful lead. The selection of solder gauge also matters—usually, a thinner gauge around 0.6mm to 0.8mm works best for battery connections. This size allows for precise application without excessive bulk. Always ensure that the soldering techniques used adhere to safety standards and protocols to enhance the durability and reliability of the connections.

IS IT SAFE TO SOLDER BATTERIES MYSELF?

Soldering batteries can be done safely with appropriate knowledge and tools. Employing proper techniques minimizes risks associated with overheating or causing short circuits. Always wear safety gear, such as goggles and gloves, to protect against potential hazards. If this task seems daunting or your comfort level with soldering is low, consider enlisting the help of an experienced individual or a professional. Knowledge of electrical circuits can greatly enhance safety and ensure successful soldering outcomes.

Executing the soldering of solar lamp batteries involves several critical elements. Proper preparation, safety protocols, and meticulous execution are key to successful replacements. Understanding the components, the tools required, and the steps to carry out this task can not only maximize efficiency but also extend the lifespan of your solar lamp. After gathering the necessary tools and components, ensuring you select the right type of solder and working with clean, well-prepped batteries leads to secure connections. Following safe soldering techniques minimizes risks. Testing the solar lamp post-soldering provides reassurance of functionality, ensuring it serves your outdoor space as intended. Moreover, recognizing signs of battery failure ahead of time facilitates timely replacements, contributing to a seamless transition and top-tier performance of the lamp. With the guidance provided, tackling the task of soldering your solar lamp batteries can be both straightforward and effective, empowering users to maintain their solar devices with confidence.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-solder-solar-lamp-batteries/