Setting up a solar temperature control valve involves several steps to ensure optimal performance and efficiency. 1. Proper installation procedures must be followed, including ensuring compatibility with solar systems, selecting an appropriate location for mounting, and securing all necessary tools. 2. Regular maintenance checks are essential to ensure the valve operates correctly, preventing potential failures. 3. Understanding the system’s specifications, such as pressure and flow rates, is crucial for effective setup. 4. Familiarizing oneself with the manufacturer’s guidelines ensures compliance and aids in troubleshooting. A detailed approach to these elements will significantly enhance the efficacy of the solar temperature control valve, contributing to an optimized solar heating system.

1. UNDERSTANDING SOLAR TEMPERATURE CONTROL VALVES

Solar temperature control valves play a pivotal role in the functionality of a solar heating system, primarily by regulating the flow of water based on temperature fluctuations. These valves ensure that the optimal amount of heated water circulates through the system, enhancing energy efficiency. When the temperature of the water in the solar collector exceeds a set point, the valve opens, directing water to storage tanks or heating systems, while maintaining a steady temperature. This mechanism not only conserves energy but also minimizes heat loss.

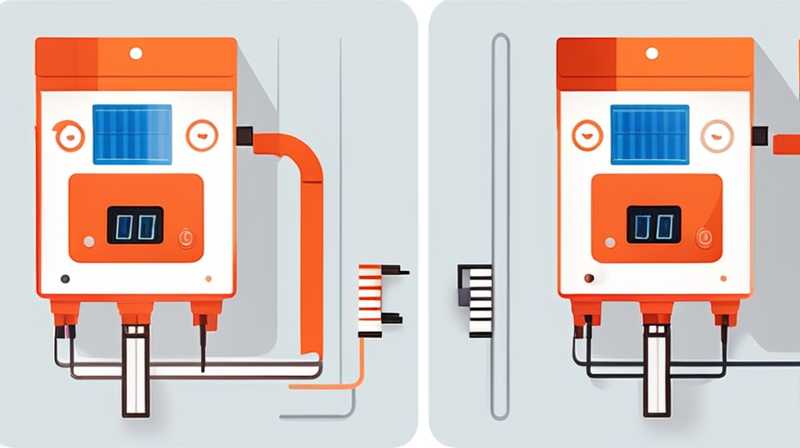

The technology behind these valves can vary, ranging from mechanical to electronic control systems. Mechanical systems may operate using simple wax elements that expand with heat, whereas electronic systems often integrate sensors and controllers for more precise regulation. Both types aim to maintain water temperature within sustainable limits, allowing for effective energy use. Understanding how these valves operate in different solar setups assists in making informed decisions during installation and maintenance.

2. PREPARING FOR INSTALLATION

Before commencing installation, the essential first step is thorough preparation. This phase should include assessing the existing solar system setup and determining the best location for the valve. During this assessment, factors like sunlight exposure, accessibility, and proximity to existing plumbing should be weighed. Proper site selection can significantly influence the valve’s efficiency and response time.

A detailed list of required equipment should be compiled, ensuring that all necessary tools and materials are on hand. Equipment typically includes wrenches, sealants, and pipe fittings. Additionally, a contingency plan for potential installation challenges must be developed. Identifying possible issues such as pipe sizing discrepancies or unexpected system configurations ahead of time can facilitate a smoother installation process.

3. INSTALLATION PROCESS

Upon preparing adequately, one can dive into the installation phase. First, isolate the area of installation by shutting off the system and draining any residual water. This precaution not only ensures safety but also prevents any water damage. Next, position the valve correctly in the pipeline, ensuring that it’s oriented according to the manufacturer’s guidelines. This orientation is critical for proper functionality, as incorrect placement can lead to inefficient temperature regulation.

After placing the valve, secure it tightly using the appropriate fittings. It is essential to apply thread sealant to avoid leaks, which can significantly impact system efficiency. Once the valve is installed, it’s time to reconnect the system. This step should be followed by a gradual reintroduction of water to the system while keeping an eye out for leaks or irregular sounds. A successful installation not only involves appropriate physical positioning but also checks to see that the valve is functioning per the expected parameters.

4. CALIBRATION AND TESTING

Following installation, calibration is the next critical step. It involves setting the temperature points at which the valve will open and close. Accurate calibration ensures that the system operates within the desired temperature range without unnecessary cycling. This process typically requires specialized thermometers and might involve trial and error to achieve optimal results.

Testing the solar temperature control valve through simulated conditions is also vital. Simulating temperature conditions allows for a better understanding of how the valve responds to different thermal inputs. Continuous monitoring, particularly during early operation, provides insights into the valve’s functional performance and helps identify any unforeseen issues that may arise.

5. MAINTENANCE

Regular maintenance ensures the continual efficiency of a solar temperature control valve. This process includes periodic inspections for any signs of wear, corrosion, or blockage in the system. Establishing a maintenance schedule based on system usage and environmental conditions is crucial for longevity and optimal performance. Typically, valves should be inspected at least annually or biannually.

During maintenance cycles, it is essential to perform cleaning procedures. This could involve flushing out sediment and debris from the valve and checking for proper lubrication. Special attention should also be paid to the mechanical components if applicable, as wear and tear can critically affect the valve’s operation.

6. IMPLEMENTING AUTOMATED SYSTEMS

Advanced solar temperature control valves integrate automation technology to optimize performance. These systems use sensors to detect real-time temperature variations and adjust flow accordingly. Implementing such automation can greatly enhance energy conservation, reducing user intervention in daily operations.

Additionally, incorporating smart technology allows for remote monitoring and control of the solar heating systems, thereby enhancing user convenience. Considerations should include compatibility with various smart home ecosystems. The flexibility to adjust settings via mobile applications provides opportunities for increased efficiency and user satisfaction.

7. OPTIMIZATION STRATEGIES

Identifying and implementing optimization strategies can lead to significant improvements in system performance. For instance, integrating thermal storage solutions may enhance the efficiency of heat distribution, while properly insulating pipes reduces energy losses. These strategies contribute to an overall increase in the effectiveness of solar heating applications.

Harnessing data analytics is another avenue for optimization. Analyzing performance metrics can uncover patterns and areas needing improvement, allowing users to make informed adjustments to their systems. Such data-driven insights are invaluable for enhancing operational efficiency, reducing costs, and extending the lifespan of the equipment.

8. TROUBLESHOOTING COMMON ISSUES

Despite careful planning and execution, common problems may still arise in solar temperature control valves. Potential issues include incorrect valve settings, blockages, or sensor malfunctions. Recognition of symptoms is vital for prompt resolutions. For example, if a valve frequently cycles without reaching set temperature points, it may indicate a calibration issue or need for further inspection.

Should problems escalate, consulting with experts or manufacturers is advisable. They can provide insight into advanced troubleshooting techniques or recommend suitable replacement parts as necessary. Investing in training sessions or resources to better understand the valve’s intricacies may ultimately prove beneficial.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR TEMPERATURE CONTROL VALVE?

A solar temperature control valve is a device designed to regulate the flow of heated water within a solar heating system. The primary function of this valve is to maintain an optimal water temperature by controlling when to open or close based on set temperature parameters. This regulation ensures that energy produced by solar collectors is utilized efficiently and prevents overheating or excessive cooling of water.

Solar temperature control valves typically exist in various types, including mechanical and electronic systems. Each type operates slightly differently, but both aim to achieve the same goal: effective temperature management. Properly installed and maintained, these valves can significantly enhance the efficiency and reliability of solar heating systems. Users should familiarize themselves with their specific valve model to ensure optimal functionality.

HOW CAN I MAINTAIN MY SOLAR TEMPERATURE CONTROL VALVE?

To maintain a solar temperature control valve effectively, one must schedule regular inspections to monitor its performance. During these inspections, looking for signs of wear, leaks, or blockages is crucial. Addressing any identified issues promptly can help ensure the valve works optimally.

Cleaning is also a significant aspect of maintenance. Removing sediment and debris from the valve’s components can prevent blockages and inefficiencies, which typically arise over time. Regular lubrication of mechanical parts, if applicable, is essential to ensure smooth operation. Establishing a comprehensive maintenance routine can extend the lifespan of the valve and improve the entire system’s performance over time.

WHAT SHOULD I DO IF MY VALVE IS NOT FUNCTIONING CORRECTLY?

In cases where a solar temperature control valve is not functioning as expected, identifying the underlying issue is the first step. Common signs that a valve may not be operating correctly include unusual noises, failure to maintain set temperature points, or erratic cycling. Begin troubleshooting by checking for blockages and inspecting the calibration settings.

If basic troubleshooting does not resolve the issue, consulting with the valve’s manufacturer or a professional installer may be necessary. They can provide expert guidance tailored to the specific valve model, helping diagnose complex issues. Investing in proper training can empower users to handle minor issues independently, improving the overall efficiency of the solar heating system.

Establishing a solar temperature control valve requires careful planning, precise execution, and ongoing maintenance. Understanding various valve types, proper installation techniques, calibration, and effective maintenance practices significantly impact overall performance. Adopting advanced technologies can further enhance efficiency and user convenience. Regular assessments and prompt attention to any identified issues will ensure longevity and optimal function of the system. By prioritizing education and proactive measures, users can maximize the benefits of their solar temperature control valves, ultimately contributing to sustainable energy practices and reduced costs.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-set-up-the-solar-temperature-control-valve/