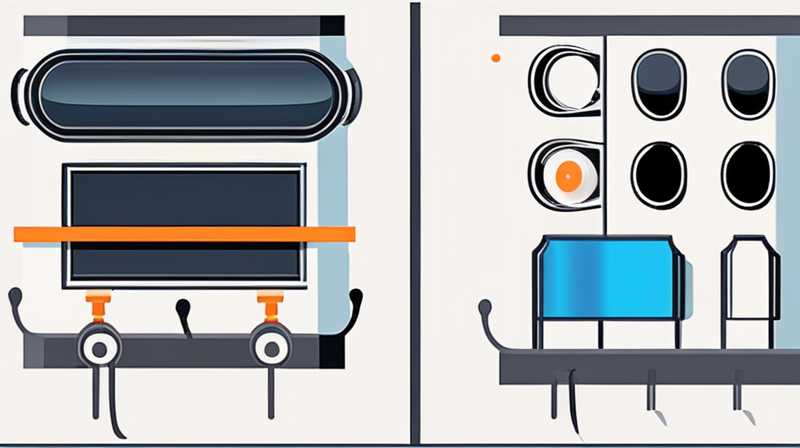

Setting up a solar pressure relief valve involves several critical steps to ensure safety and efficiency. 1. Understand the components involved; a solar pressure relief valve typically consists of a valve body, a spring, and a sealing mechanism to prevent backflow. 2. Identify the proper location for installation, ideally close to the solar collector outlet, to relieve excess pressure effectively. 3. Follow installation procedures meticulously, ensuring that all connections are secure and compliant with local regulations to avoid any potential hazards. 4. Perform routine maintenance checks to ensure its proper functioning. Regular inspections can prevent unexpected failures or safety issues. These elements are crucial in managing the thermal energy within a solar system effectively, minimizing the risk of overheating or damage to the system.

1. UNDERSTANDING THE IMPORTANCE OF A SOLAR PRESSURE RELIEF VALVE

In the world of renewable energy, solar heating systems see increased deployment across residential and commercial structures. Central to the functionality of these systems is the solar pressure relief valve, which mitigates risks associated with overheating and pressure buildup. It plays a vital role not just in system efficiency but also in safety, as it helps prevent catastrophic failures that may stem from excessive pressure.

A pressure relief valve is designed to open at a predetermined high pressure, thus allowing excess fluid to escape and maintaining safe operational limits within the solar thermal system. The reliance on this component cannot be overstated; without it, solar systems can suffer not only from thermal energy inefficiency but also from significant physical damage, terminating their operational lifespan prematurely. In addition, the potential for water leaks, physical injuries, and costly repairs places a considerable degree of importance on proper setups.

2. SELECTING THE APPROPRIATE VALVE

Choosing the right model is essential when setting up a solar pressure relief valve. There are various types on the market, each catering to different system requirements and pressures. Evaluating specific pressure ratings is crucial — for instance, a standard valve typically operates between 50 to 80 psi. Choosing one not tailored for your system can lead to inefficient pressure management and increase the chances of corrosion or mechanical failure.

When selecting a pressure relief valve, it’s also important to consider the material compatibility. This involves ensuring that the valve is made from corrosion-resistant materials that can withstand high temperatures and pressures over time. The choice of materials will also impact the valve’s durability and reliability. For instance, brass or stainless steel options can offer prolonged service life compared to plastic counterparts in high-temperature environments.

3. PREPARING FOR INSTALLATION

Preparation for the installation process requires a comprehensive understanding of the entire solar system layout. Before any installation begins, ensure that all necessary tools and components are on hand. Basic tools like wrenches, screwdrivers, and tubing cutters will be required. It’s equally crucial to consult installation manuals or industry guidelines tailored for the specific valve model you will install.

Additionally, identify the most effective installation location. This is often near the highest point of the water or thermal fluid circulation within the solar system. Proper positioning helps ensure that the valve can adequately relieve excess pressure, enhancing the overall system reliability. Incorrect placement may render the pressure relief valve ineffective, risking serious system failure and hazards associated with high-pressure conditions.

4. INSTALLATION STEPS

The installation process for a solar pressure relief valve is systematic. Begin by shutting down the solar heating system to prevent any accidents caused by pressurized fluids. After ensuring the system is depressurized, remove any existing fittings at the chosen installation site. Once the area is clear, inspect it meticulously for any damage or corrosion that may need addressing prior to valve installation.

Next, connect the valve in line with the system piping. Make sure that the orientation matches the flow direction indicated on the valve, as this will ensure its effective operation. Use Teflon tape on threaded connections to prevent leaks, tightening them securely without over-tightening, which can lead to potential fractures in the valve or connections. After everything is connected, restart the system and monitor the valve’s operation carefully.

5. TESTING THE VALVE

Upon installation, it is vital to conduct functional tests to ensure that the solar pressure relief valve is operating correctly. Start by gradually increasing the system pressure to its operational limits, keeping an eye on the behavior of the valve. During this test, observe for any indications of failure, such as leaks or unexpected opening of the valve.

It is of utmost importance to confirm that the valve opens when the pressure threshold is reached. If everything checks out positively, continue to monitor the system closely over the next few days or weeks, as this can reveal any early indicators of malfunctions. Regular testing should be included in your maintenance routine, ensuring that the valve remains in optimal working condition throughout its service life.

6. MAINTAINING THE VALVE

Long-term functionality of the solar pressure relief valve is contingent upon regular maintenance. As with most components within solar systems, wear and tear can impede performance. Routine inspections should take place at least once every six months, assessing the valve’s integrity and surrounding connections.

During these inspections, check for leaks around the valve body and fittings, ensuring that no thermal fluid escapes. Additionally, activate the valve manually if possible, observing whether it opens smoothly under pressure. Any signs of rust, corrosion, or blockages necessitate immediate attention. Maintaining clear pathways around the valve also allows for easier access in emergencies or during routine checks, promoting overall safety.

7. COMMON ERRORS IN INSTALLATION

Common pitfalls during the installation of pressure relief valves can lead to operational failures and safety hazards. One prevalent mistake is neglecting to ensure proper placement in relation to the solar system’s high-pressure zones. Another frequently observed error is improper torque applied to the valve fittings. An overtightened connection can cause straining on valve seals or even damage to the fitting or valve itself.

Not following the manufacturer’s specifications can also result in undesirable consequences. Each model may come with specific guidelines regarding pressure limits, connection types, and mounting requirements. Skipping these directions compromises the valve’s integrity and potentially the entire solar heating system.

8. REGULATORY CONSIDERATIONS

Depending on the region, local building codes and regulations must be adhered to when installing solar pressure relief valves. Some areas may mandate specific valve types, pressure ratings, or materials. Familiarize yourself with these requirements before proceeding to installation, ensuring compliance to avoid legal repercussions, safety hazards, or possible insurance denials in case of incidents.

Consulting a certified professional can simplify this aspect. They are well-versed in regulatory frameworks and can guide both installation and compliance processes effectively. Failing to follow appropriate guidelines can lead to diminished system performance and increased risks related to pressure buildup and overheating.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS OF A FAULTY PRESSURE RELIEF VALVE?

Several indicators may point to pressure relief valve issues. One primary sign is persistent leaking around the valve body, suggesting a failure of seals or improper installation. Unusual noises may also emerge, such as hissing or whistling, which indicate that pressure is escaping unintentionally.

Additionally, if the valve opens too frequently or not at all, this could signify a malfunction. An erratic operating pattern directly undermines the competency of the entire solar system, posing serious risks associated with overheating. Performing routine inspections and tests is crucial for identifying such issues in their early stages, preventing potential system failure or safety hazards.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR PRESSURE RELIEF VALVE?

Regular maintenance is essential for any essential component of a solar heating system, including pressure relief valves. It is generally advisable to perform maintenance checks every six months to a year. These inspections involve checking for leaks, manually activating the valve to verify functionality, and ensuring that no debris or corrosion is present.

During inspections, observing the reservoir or piping for signs of overheating or other abnormalities is beneficial. If significant fluctuations in system performance are noted, more frequent checks may be necessary. Proactive maintenance ensures that the valve operates efficiently, increasing the longevity of the solar thermal system.

WHAT HAPPENS IF THE PRESSURE RELIEF VALVE FAILS?

A failure of the pressure relief valve can have serious repercussions. If the valve remains closed under excessive pressure, the system can conduct pressure levels that exceed safe thresholds, leading to potential ruptures in pipes or collectors. This could result in significant damage to the solar system or even house-related fire hazards.

In extreme cases, a pressure surge can lead to water or thermal fluid ejection, creating safety risks for anyone in proximity. It’s essential to prioritize regular checks and immediate repairs or replacements when any signs of valve failure are detected, thus safeguarding the integrity of the solar heating system and the safety of the property.

Establishing a solar pressure relief valve requires meticulous attention to detail and adherence to safety protocols. To summarize the critical aspects: 1. Understanding the components and their roles is paramount; ensuring the right valve type and materials can prevent many problems down the line is crucial. 2. Preparation for installation forms a crucial part of the process; these steps ensure proper positioning and tools are readily at hand. 3. Installation involves systematic procedures, including checking flow direction, using viable sealing methods, and securing the connections adequately. 4. Proper testing procedures guarantee that the valve operates correctly upon installation; regular maintenance extends the system’s life while confirming ongoing functionality. 5. Being cognizant of common errors is fundamental; understanding local regulations fortifies safety and compliance. By comprehensively implementing these considerations, one can achieve an effective and reliable solar pressure relief valve setup.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-set-up-a-solar-pressure-relief-valve/