1. DETAILED EXPLANATION OF REMOVAL PROCESS, 2. IMPORTANT TOOLS REQUIRED, 3. SAFETY MEASURES TO CONSIDER, 4. POST-SEPARATION STEPS

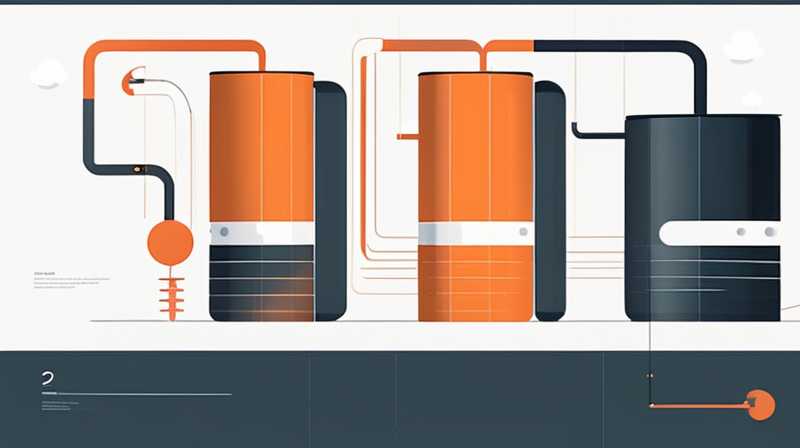

To effectively separate the inner tank of a solar tube, one must follow a systematic approach involving several steps. The key actions include: 1. Utilizing appropriate tools to facilitate the separation, 2. Carefully assessing the structure of the solar tube to identify potential disconnect points, 3. Adhering to safety protocols to prevent injury or damage, 4. Executing the separation methodically to ensure that both tank components remain intact.

1. DETAILED EXPLANATION OF REMOVAL PROCESS

The initial phase of this endeavor centers on understanding how to separate the inner components without causing any damage. The first step involves examining the solar tube to determine the mounting procedures and joint types employed in the assembly. In many cases, solar tubes are designed with specific fittings, which may include adhesive seals or mechanical fasteners.

A thorough inspection allows for identifying the best approach to disassemble the system without compromising its integrity. Once potential disassembly points are identified, careful planning should take place to ensure that the assembly can be reassembled in the same condition if necessary. The inner tank’s purpose must also be considered; if meant for water storage or heat exchange, then any transfers of materials must be conducted with care to preserve the capabilities of both storage and utilization.

Following an understanding of the assembly, preparation for removal is crucial. One should ensure that all components are cooled down or emptied of fluid prior to commencing work. Engaging in this task without addressing temperature or fluid contents could result in hazardous spills or burns, thus endangering the individual performing the procedure.

After ensuring safety, the following step is to utilize suitable tools designed for the task at hand. Often, a combination of wrenches, screwdrivers, and pliers may be needed, and having these on hand will facilitate an efficient process. Once the workspace is organized and the appropriate tools are ready, the careful detachment of the inner tank can commence.

2. IMPORTANT TOOLS REQUIRED

Having the right tools at one’s disposal is paramount when working to separate the inner tank from the solar tube system. Essential components typically include ratchet sets, insulating gloves, clamps for holding parts steady, and various screwdrivers that are adjusted for precision work.

Many people overlook the importance of safety gear; however, investing in heat-resistant gloves and glasses can provide essential protection against accidental spills or debris flying during the separation process. The right tools not only minimize damage to materials involved but also ensure that the work proceeds smoothly.

Performance of these tools is best evaluated before beginning the task, as broken or inadequate tools can increase the risks of creating unsafe environments or damaging components beyond repair. Preparing a checklist to confirm that each tool functions correctly may also help to avoid interruptions during the separation process, thereby maximizing efficiency.

Within the context of this operation, tools geared towards managing potential leaks are also advisable. Sealant removal tools can play a significant role; since many solar tubes may utilize sealant adhesives, having the correct tool ensures that removal does not become laborious. Depending on the specific design of the tube at hand, different tools may be needed, so preliminary research into the assembly is necessary to procure the right equipment.

3. SAFETY MEASURES TO CONSIDER

A primary aspect of this procedure cannot be overlooked: safety protocols are essential to a successful outcome when separating the inner tank from a solar tube. Before initiating the process, one must assess potential hazards present in the work environment. Identifying any risks associated with fluid contact, high-temperature surfaces, and sharp edges is crucial to maintain safety throughout the task.

Furthermore, personal protective equipment (PPE) is non-negotiable when considering safety measures. Attire should ideally include gloves to prevent burns or cuts, goggles to shield eyes from debris or splashes, and hard hats in environments where overhead components might pose risks. Though each job can present unique challenges, these fundamental forms of protection cover a broad spectrum of possible incidents.

Moreover, it’s advisable to work in well-ventilated areas, especially if any solvents or adhesives will be used in the separation process. Proper air circulation assists in minimizing exposure to harmful vapors that can lead to respiratory issues. It also helps to keep a fire extinguisher nearby in case of emergencies, especially if working with flammable materials.

Another vital safety consideration is the emotional state of the individual performing the task. Working with a clear mind and avoiding distractions helps maintain focus on the job at hand. If fatigue sets in, consider taking breaks, as prolonged sessions can lead to lapses in concentration, potentially resulting in accidents or injury.

4. POST-SEPARATION STEPS

Once the inner tank has been successfully removed, a few critical steps remain to ensure that materials are not only maintained properly but also ready for reinstallation or repurposing. The first task involves cleaning and inspecting both the inner tank and outer casing for any signs of wear, leakage, or damage. Evaluating these components is essential, as any imperfections may lead to issues upon reassembly or further use.

Cleaning involves not only the removal of debris but also the careful examination of seals and connections that will impact the tank’s performance. It’s vital to ensure that any build-up or residue is meticulously cleared away, as this can often interfere with the proper fitting and functionality of the parts involved.

Reassembly preparations must also consider the materials used in fixing or reattaching the inner tank. Utilizing fresh seals and high-quality adhesives ensures that the connection remains airtight and operational for the foreseeable future. Following the mother procedures outlined above, it is wise to read thoroughly through assembly guides that may provide specific instructions tailored to the particular type of solar tube being handled.

Before concluding this operation, a thorough re-inspection of the entire system should be conducted. Operational tests can further help identify any underlying issues that weren’t apparent during initial inspections. Confirming that each section fits seamlessly together is vital in ensuring the longevity and efficiency of the solar tube system.

FAQs

HOW CAN I IDENTIFY THE RIGHT TOOLS FOR THE REMOVAL OF THE INNER TANK IN A SOLAR TUBE?

Selecting the appropriate tools for removing the inner tank in a solar tube includes assessing the assembly type and the materials involved. Key tools include wrenches, screwdrivers, and pliers suited for precision work, allowing for an efficient separation process. Consider investing in sealant removal tools and safety equipment like gloves and goggles to protect against spills and sharp edges. It’s advisable to refer to assembly guidelines specific to the solar tube being worked on, as this can direct tool selection more accurately. In some cases, purchasing a tool kit specifically tailored for solar installations may also prove beneficial.

WHAT KIND OF SAFETY GEAR SHOULD BE USED DURING THIS PROCESS?

Ensuring safety during the separation of the inner tank from a solar tube necessitates comprehensive protective attire. Essential safety gear includes heat-resistant gloves to shield against burns, goggles to protect from potential flying debris, and hard hats for additional head protection. If there are any flammable materials involved, additionally having a fire extinguisher close by is prudent. Furthermore, consider wearing insulating wear to minimize exposure to any potential spills during this task. Finally, it is paramount to work within a well-ventilated space to mitigate risks associated with inhalation of any fumes.

WHAT ARE THE COMMON BLUNDERS TO AVOID DURING THE SEPARATION OF THE INNER TANK?

Several pitfalls commonly arise when attempting to separate the inner tank from a solar tube. A prevalent mistake involves neglecting to prepare adequately by checking all tools before commencing the task. Inadequate preparation can result in unnecessary delays or equipment failure. Another blunder is failing to observe proper safety precautions, which may expose individuals to hazards such as burns or chemical exposure. Lastly, underestimating the time required for careful inspection of materials after separation can lead to future inefficiencies or failures upon reassembly. It is crucial to approach the process with patience, following every step methodically while ensuring all risks are minimized.

Ensuring a successful separation of the inner tank of a solar tube involves careful planning, the right tools, adherence to safety measures, and thorough follow-up tasks. The process begins with the identification of key tools necessary for the job. It also includes a detailed analysis of potential hazards present in the work environment, necessitating the use of proper personal protective equipment to minimize risks. Once the inner tank is removed, it is imperative to clean and assess the components involved.

This reassures that they maintain optimal functionality and longevity. A systematic approach to reassembly is equally important, ensuring fresh adhesives and seals are used to retain the integrity of the setup. In essence, combining professional expertise with meticulous attention to detail is vital for accomplishing a successful separation while safeguarding both the individual and the equipment involved in solar tube processes. Taking these measures ensures that any future operations involving the solar tube will proceed as smoothly as possible, maximizing the system’s efficiency and effectiveness for its intended applications. Thus, it is essential to embrace thorough procedures from beginning to end, ensuring reliability and safety govern the entire operation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-separate-the-inner-tank-of-solar-tube/